Patents

Literature

36results about How to "Hydraulically hard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-solid waste weak concrete material prepared with solid sulphur slag of fluidized bed fire coal

The invention discloses a concrete material which totally adopts industry solids waste to replace cement preparation, comprising a gelled material and a skeletal material. The gelled material is composed of the components with the following weight portions of 36 to 75 portions of fluidized bed burning coal solid sulfur clinker, 9 to 25 portions of acetylene sludge and 6 to 15 portions of phosphogypsum; because the cementing materials such as cement, lime, asphalt, and the like, are not needed at all, material costs are remarkably reduced, great amount of industry solids waste is used to produce building materials, especially the fluidized bed burning coal solid sulfur clinker is used to serve as raw material, environment pollution is avoided, and land resources are saved.

Owner:CHONGQING UNIV

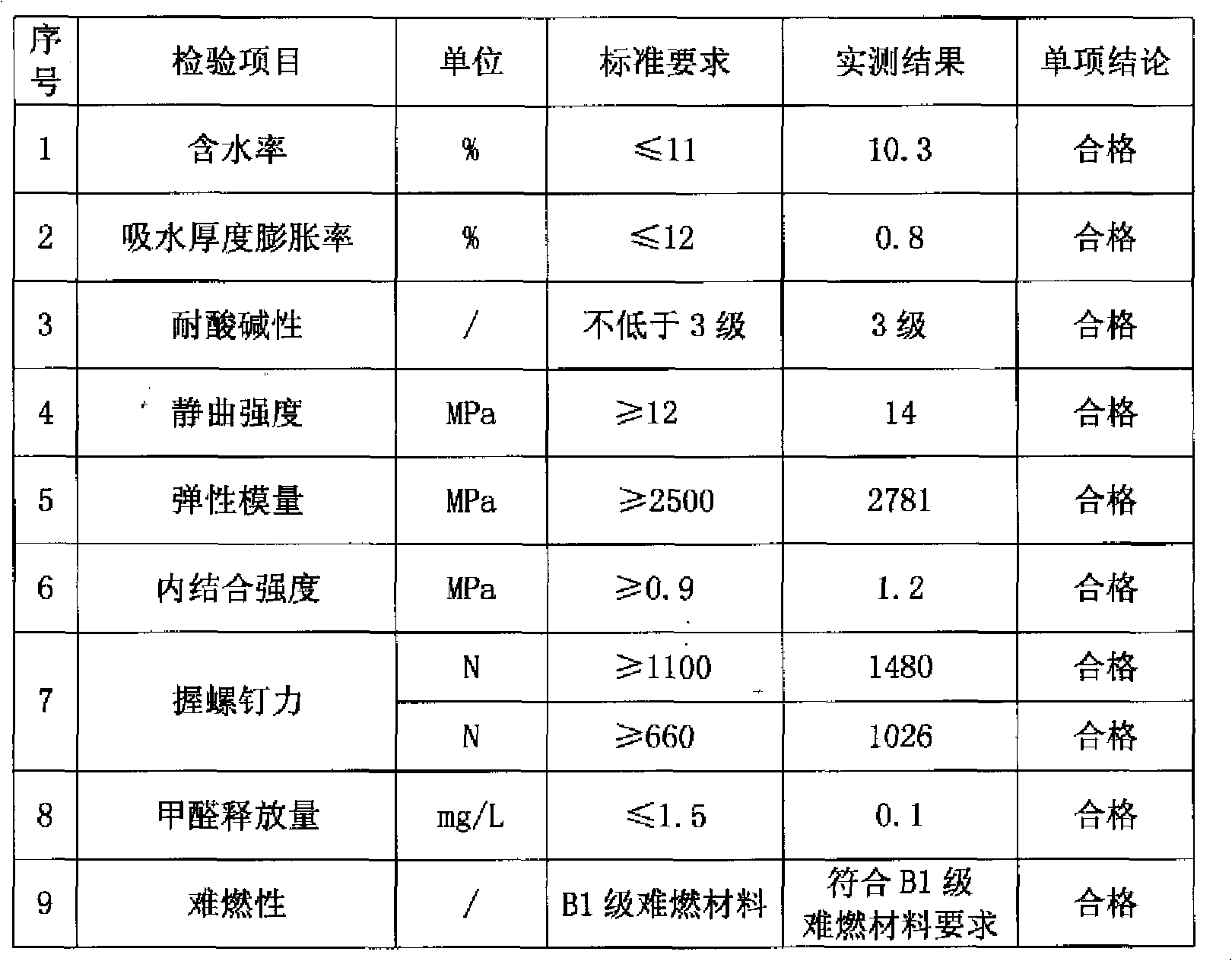

Flame-retardant fiber board and manufacturing method thereof

InactiveCN101602224ALow priceMaterials are readily availableDomestic articlesFlat articlesFiberPolymer science

The invention relates to a flame-retardant fiber board and a manufacturing method thereof. The flame-retardant fiber board is prepared from the following raw materials in portion by weight: 80 to 120 portions of fiber, 80 to 120 portions of magnesia, 80 to 200 portions of water solution of magnesium sulfate, 5 to 30 portions of active silica, 0.5 to 2 portions of organosilicon waterproof agent, and 0.5 to 1.5 portions of plasticizer. The manufacturing method comprises the steps: 1) preparing the fiber, namely cleaning and drying crop straws, wood branches or wood processing residual materials, and then obtaining the fiber through the crushing by a crushing machine; 2) preparing an inorganic adhesive, namely mixing the magnesia, the water solution of the magnesium sulfate, the active silica, the organosilicon waterproof agent and the plasticizer, and stirring the mixture to obtain the inorganic adhesive; 3) mixing the fiber and the inorganic adhesive prepared through the step 1 and the step 2, stirring the mixture, and paving the mixture after the screening by a screening machine; 4) paving a reinforcing network on the upper and lower surfaces of a paved slab; and 5) finally performing hot pressing on the board paved with the reinforcing network for 10 to 25 minutes at a temperature of between 100 and 110 DEG C at a pressure of between 12 and 30MPa to obtain the flame-retardant fiber board. The flame-retardant fiber board has broad application field.

Owner:湖南迪普环保建材有限公司

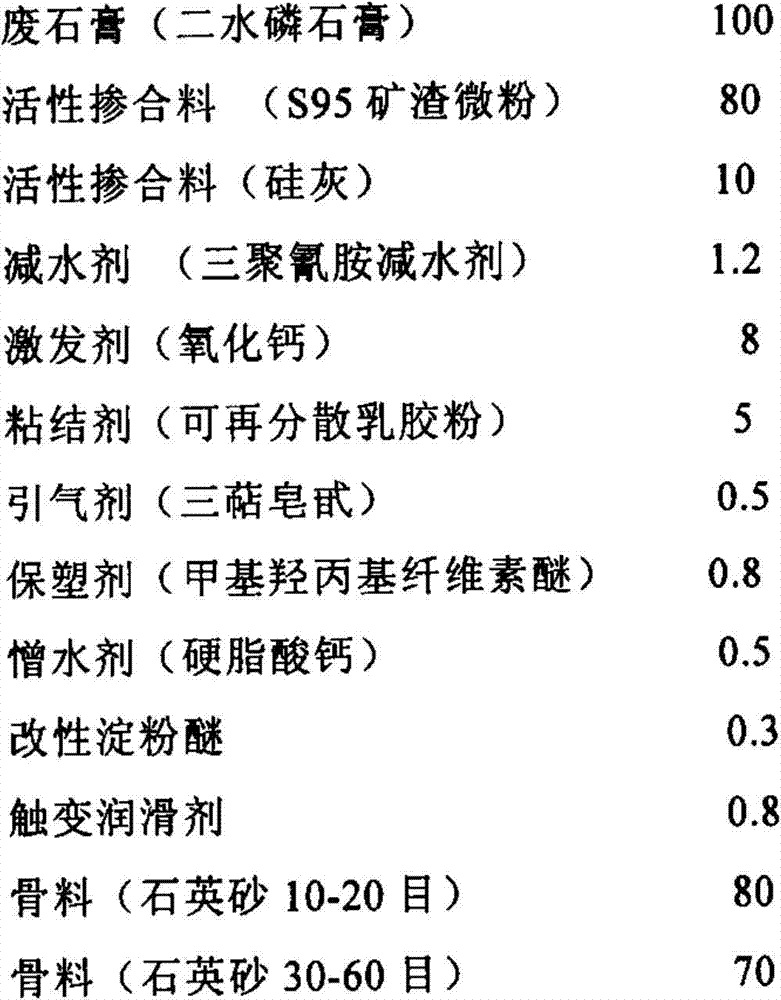

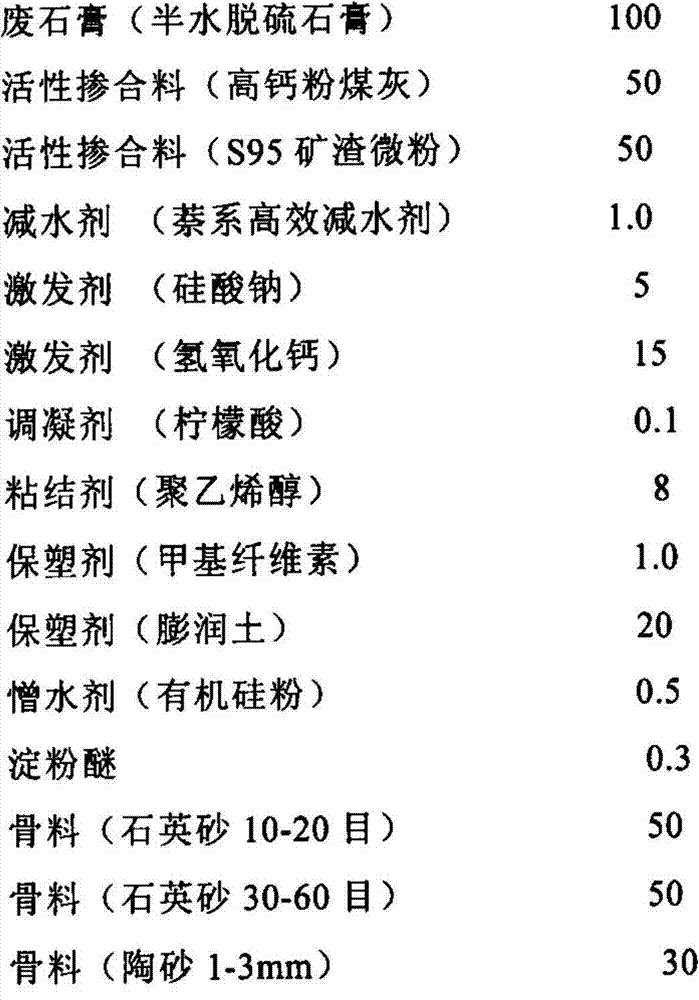

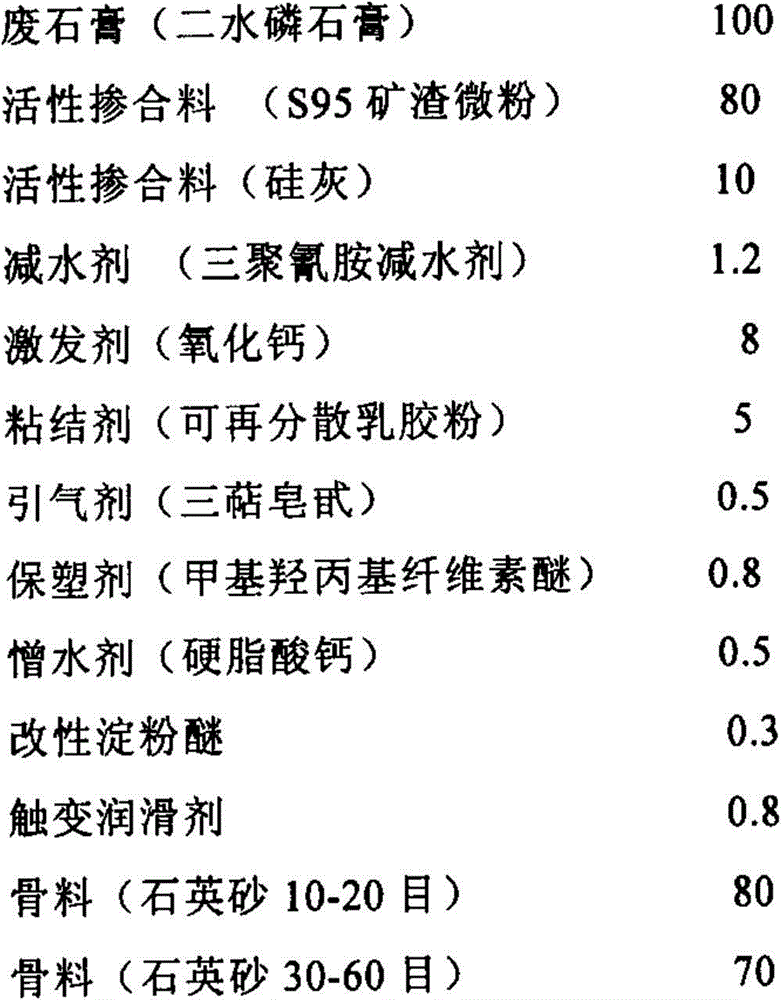

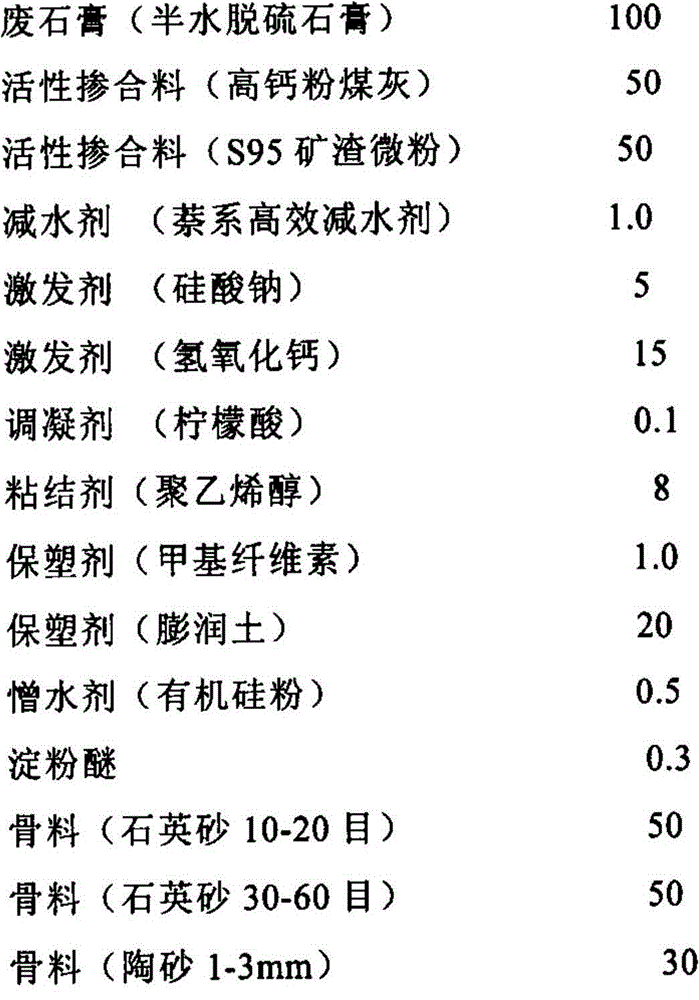

Assembly type building component joint gypsum base sealing material and application thereof

ActiveCN103496936AEasy constructionImprove plasticityBuilding constructionsResource utilizationEther

The invention relates to an assembly type building component joint gypsum base sealing material and application thereof. The assembly type building component joint gypsum base sealing material comprises, by weight, 100 parts of waste gypsum, 20-200 parts of active admixture, 0.01-10 parts of water reducer, 0.1-50 parts of excitant, 0-10 parts of thickening control agent, 0-30 parts of binder, 0-10 parts of air entraining agent, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of water repellent, 0-5 parts of starch ether, 0-10 parts of thixotropic lubricant, 0-150 parts of powder filler and 0-300 parts of aggregate, and can be applied to joint sealing after being mixed with water uniformly. Compared with the prior art, the assembly type building component joint gypsum base sealing material has the advantages of convenience in use, good filling ability, high binding power, durability, low cost and the like. In the sealing material, much industrial waste gypsum is used as gelatinization materials, so that performance of sealing mortar can be improved, material cost is reduced, pollution control and emission reduction are facilitated, and a new way for resource utilization of the industrial waste gypsum is provided.

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

Novel environment-friendly and fireproof composite biomass board

InactiveCN101786852ALow priceWide variety of sourcesSolid waste managementCeramic shaping apparatusSodium silicateScrap

The invention relates to the technical field of decorating and building materials, in particular to a novel environment-friendly and fireproof biomass board. The board is characterized by comprising the following components in percentage by weight: 65.0-75.0% of biomass packings, 15.0-25.0% of sodium silicate, 5.0-10.0% of sodium fluosilicate and 0.05-1.0% of fiberglass mesh, wherein the biomass packings are wood scraps, wood branches or crop straws. The environment-friendly and fireproof composite biomass board prepared by organically combining the wastes with good impact resistance and nail holding power, such as crop straw fibers or wood fibers, fiberglass with excellent tensile property and inorganic adhesives with unique fireproofness and waterproofness can be widely applied to the household products such as furniture, indoor and outdoor decoration of buildings, advertisement designing, building templates and other special-purpose boards.

Owner:王春莉

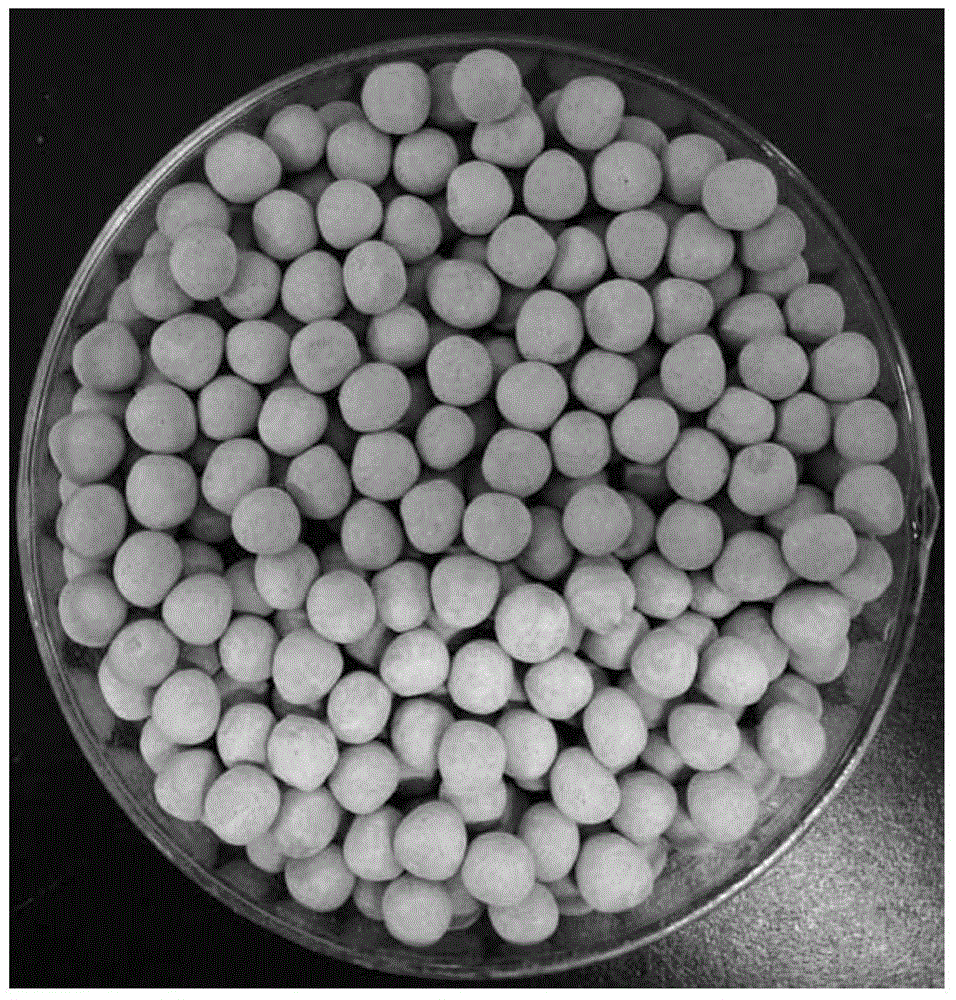

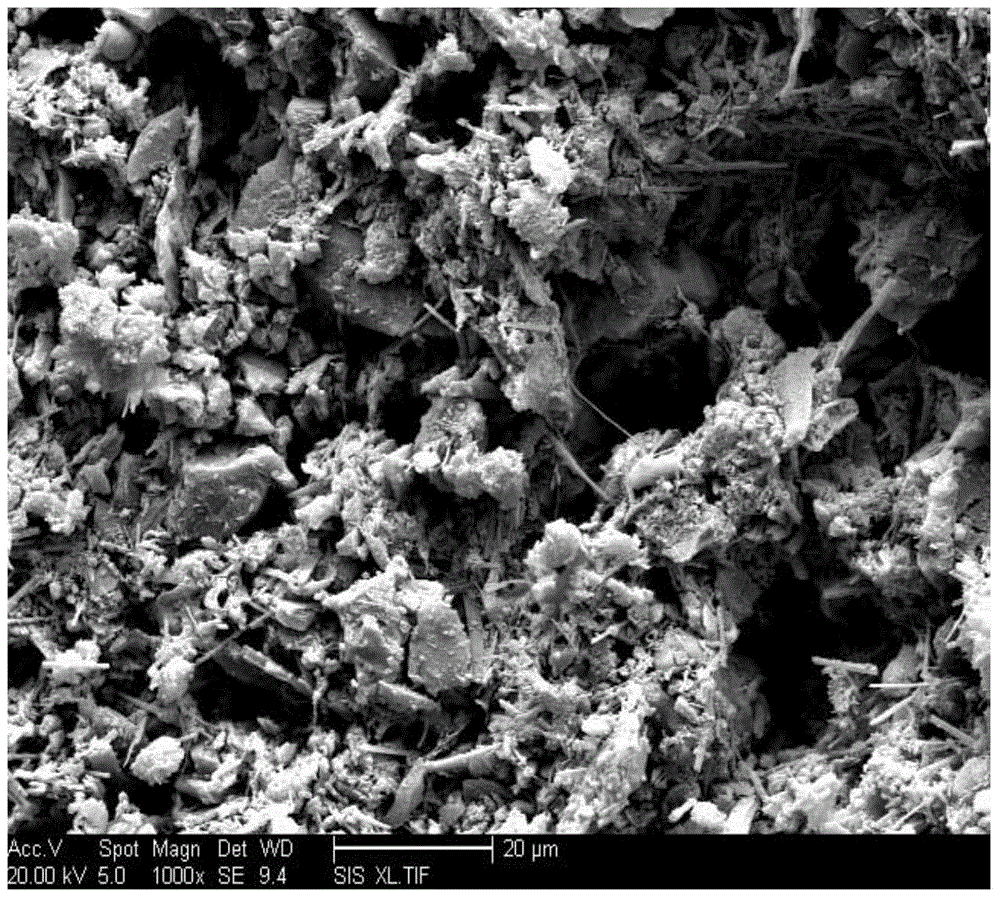

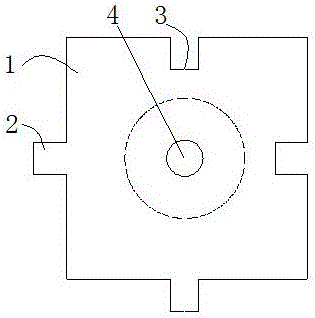

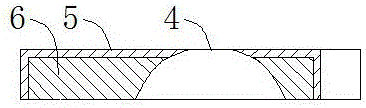

Novel non-sintered biological stuffing rapid in biofilm formation and preparation method thereof

InactiveCN103951044ALarge specific surface areaHigh porositySustainable biological treatmentBiological water/sewage treatmentSolid componentPolyvinyl alcohol

The invention provides novel non-sintered biological stuffing rapid in biofilm formation and a preparation method thereof, relating to biological stuffing and preparation methods thereof and solving the technical problems that the existing biological stuffing has long biofilm formation time and poor effluent quality in water treatment processes and preparation processes are high in energy consumption and pollute the environment. The biological stuffing is prepared from sepiolite, medical stone, cement, polyvinyl alcohol, sodium alginate, hydrogen peroxide, ferric chloride, manganese sulfate, cobalt chloride and agar. The method comprises the following steps: I. heating and dissolving polyvinyl alcohol and sodium alginate, adding hydrogen peroxide after cooling, and mixing the components uniformly, thus obtaining a liquid mixture; II. mixing the liquid mixture with other solid components, granulating the mixture, putting the granules at normal temperature, drying and sieving the granules, curing the granules at high pressure and low temperature, steam-curing the granules at constant temperature, and cooling the granules at normal temperature, thus obtaining the biological stuffing. Compared with the common ceramsite, the biological stuffing has short biofilm formation time, good effluent quality and coarse surface and is beneficial for microorganism growth. The biological stuffing is applied to the fields of environmental applied materials and sewage treatment.

Owner:HARBIN UNIV OF SCI & TECH

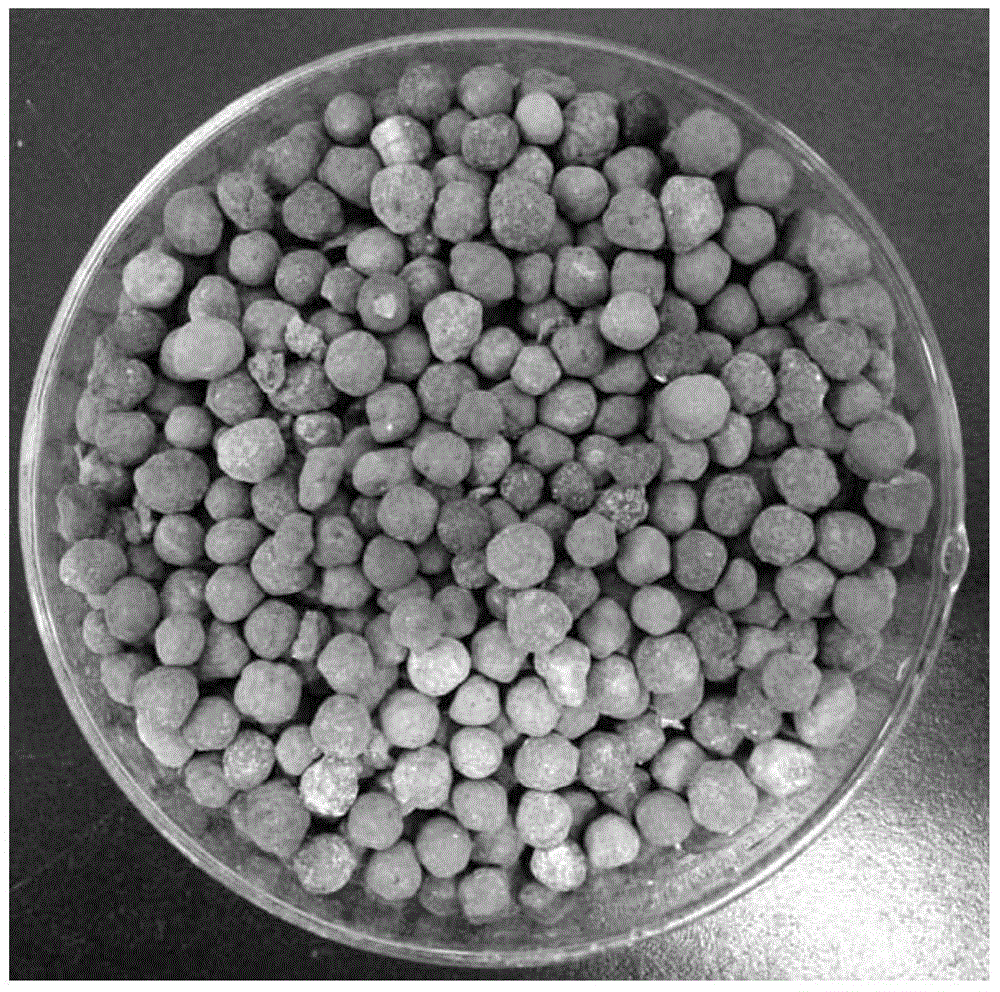

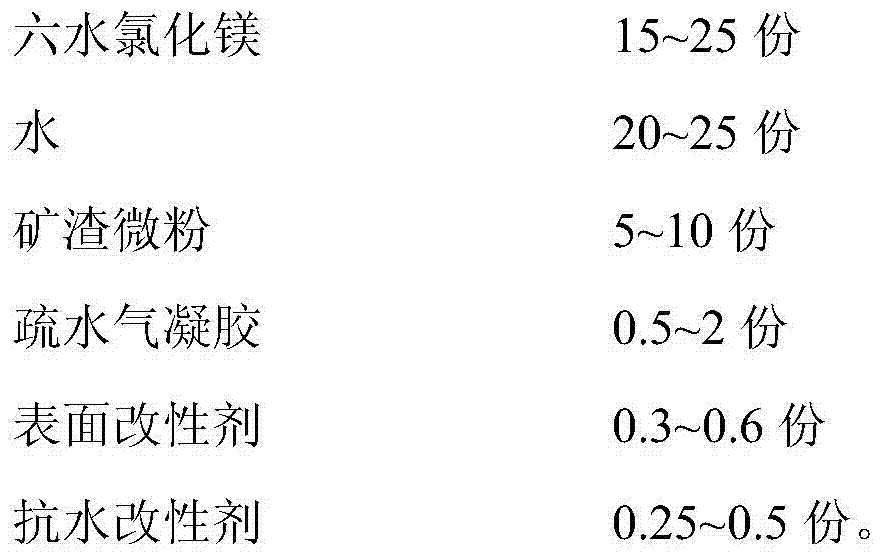

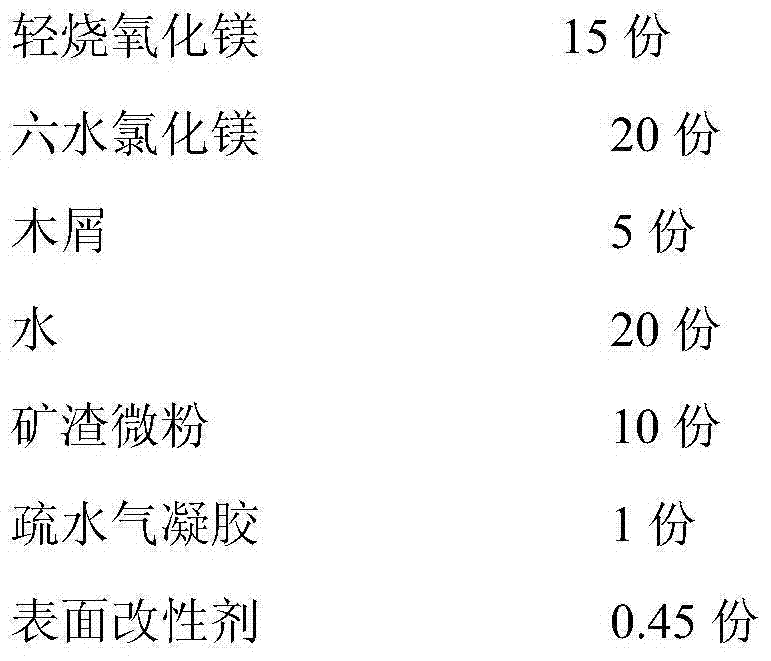

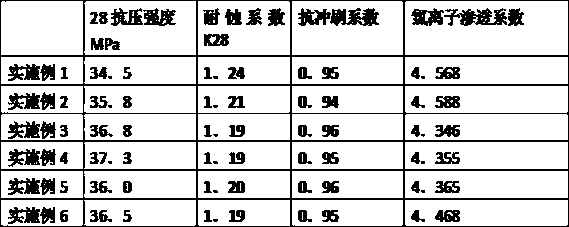

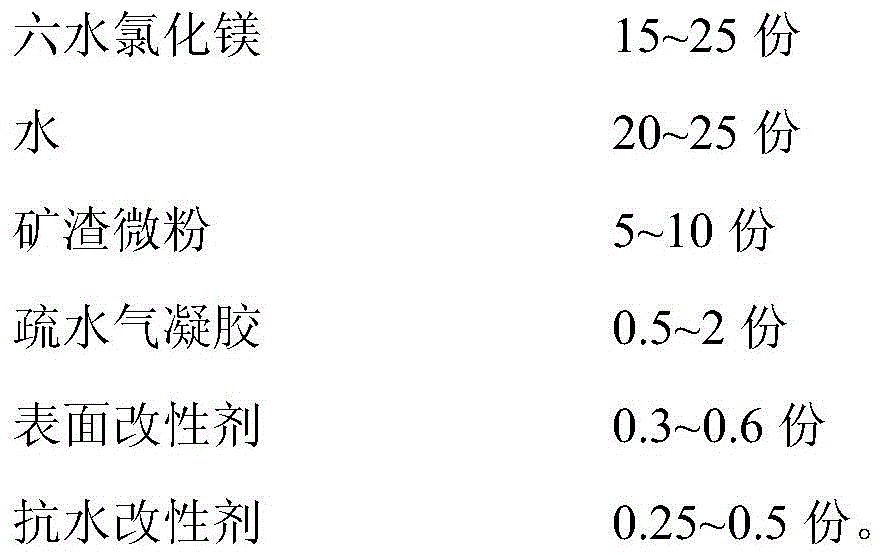

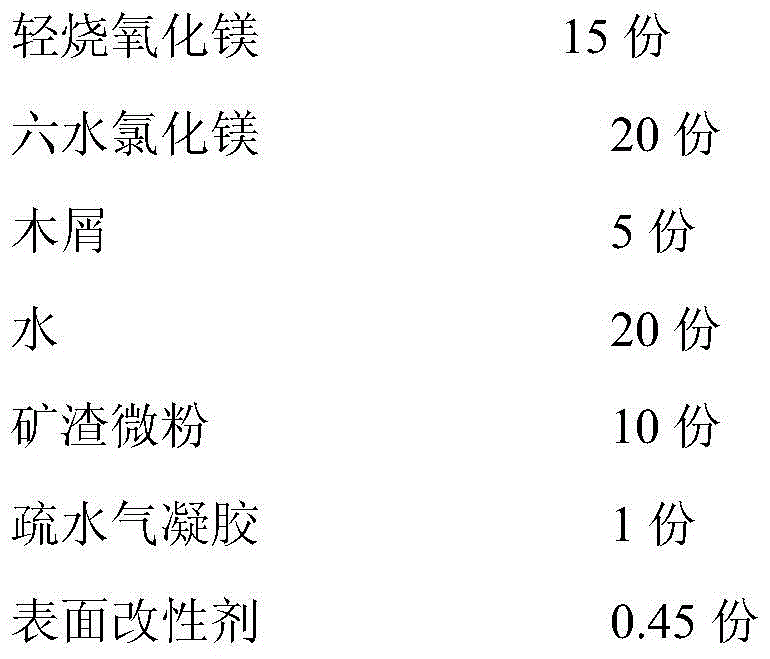

Waterproof thermal-insulation glass magnesium board and preparation method thereof

ActiveCN104744011AImproves water resistance and thermal insulationEasy to prepareSolid waste managementMagnesium chloride hexahydrateThermal insulation

The invention discloses a waterproof thermal-insulation glass magnesium board and a preparation method thereof and belongs to the technical field of preparation of new building materials from non-metallic minerals. The glass magnesium board is mainly prepared from the following raw materials in parts by weight: 10-18 parts of light calcined magnesia, 15-25 parts of magnesium chloride hexahydrate, 20-25 parts of water, 5-10 parts of superfine slag powder, 0.5-2 parts of hydrophobic aerogel, 0.3-0.6 part of a surface modifier and 0.25-0.5 part of a waterproof modifier. The waterproof thermal insulation glass magnesium board has good water resistance, hardly produces halogenide, does not warp or deform and is light in weight, thermal insulation performance is greatly improved, and quality defects of an existing glass magnesium board are overcome, and application range of the glass magnesium board is expanded.

Owner:南京格瑞恩斯新材料科技有限公司

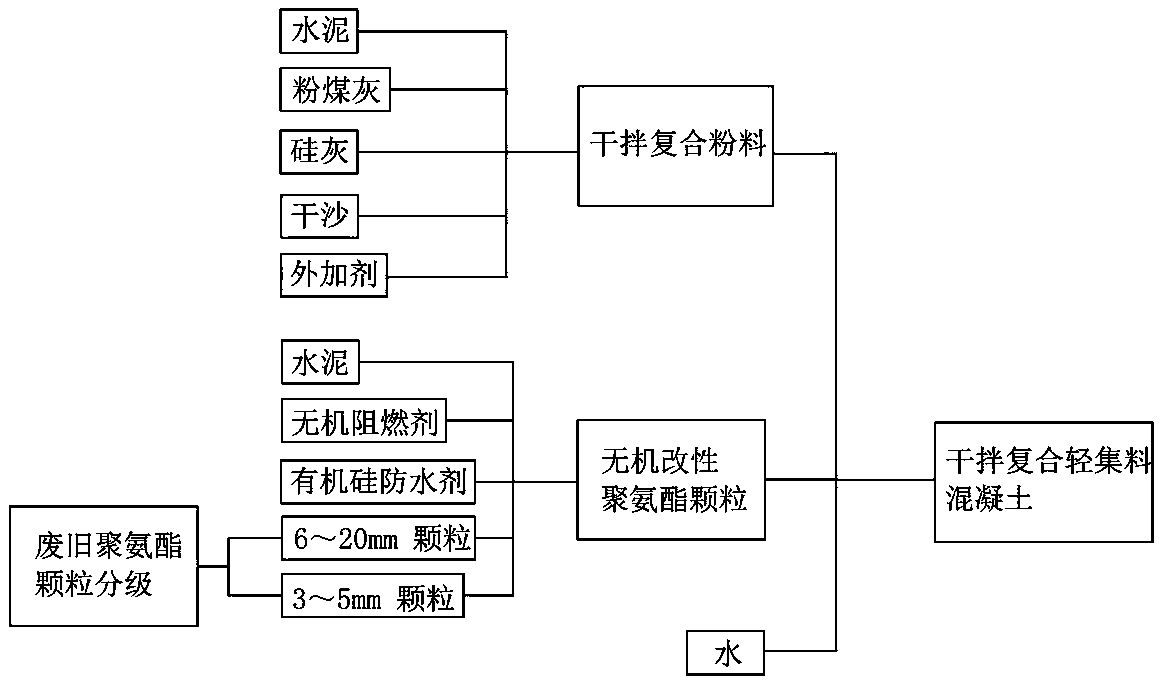

Dry-mixed composite light aggregate concrete based on inorganically modified polyurethane particles

The invention relates to dry-mixed composite light aggregate concrete based on inorganically modified polyurethane particles and a preparation method of the dry-mixed composite light aggregate concrete. The concrete is prepared from raw materials in parts by weight as follows: 38-135 parts of the inorganically modified polyurethane particles, 162-485 parts of cement, 30-127 parts of fly ash, 23-50parts of mineral powder, 3-50 parts of silica fume, 37-740 parts of dry sand, 4.6-19.7 parts of an admixture and 105-380 parts of water. The preparation method comprises the following steps: 1, wastepolyurethane particles are subjected to grain size grading; 2, the graded waste polyurethane particles are inorganically modified; 3, the cement, the fly ash, the silica fume, the mineral powder andthe admixture are added to a dry powder stirrer for uniform stirring and mixing, and dry-mixed composite powder is obtained; 4, the dry-mixed composite powder is mixed with the inorganically modifiedpolyurethane particles, water is added for stirring, and the dry-mixed composite light aggregate concrete is prepared.

Owner:河南格林循环电子废弃物处置有限公司

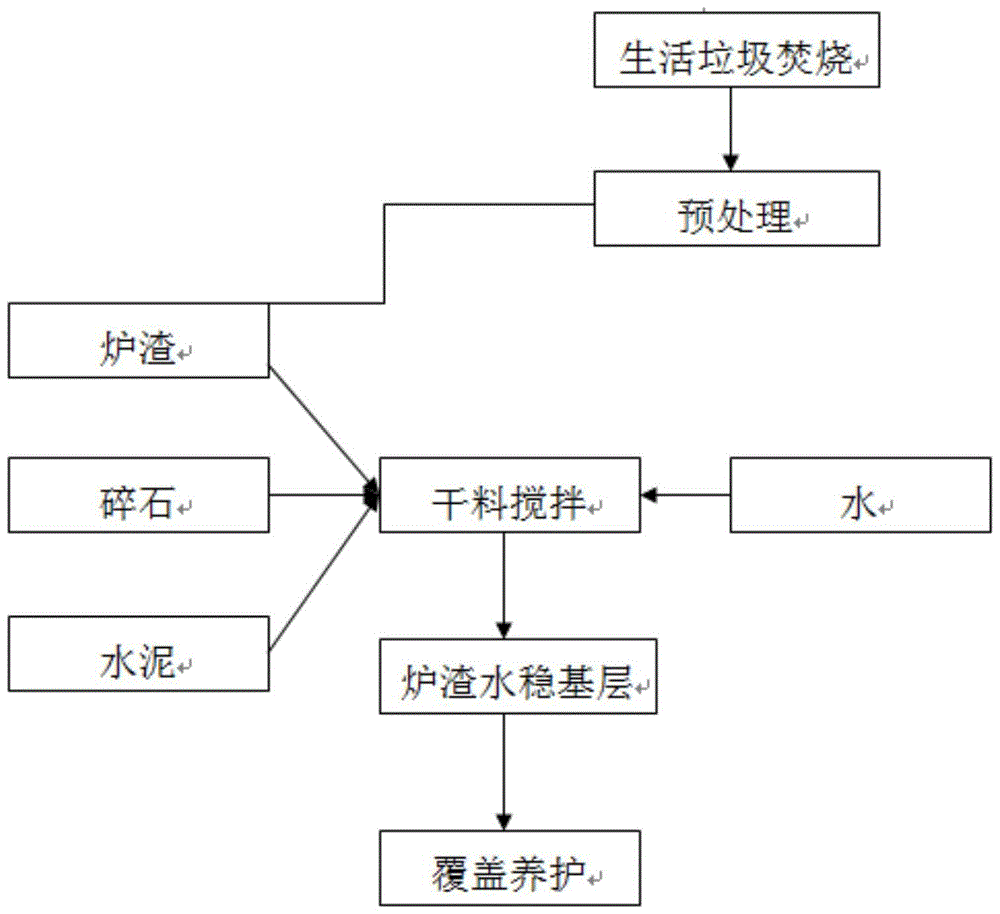

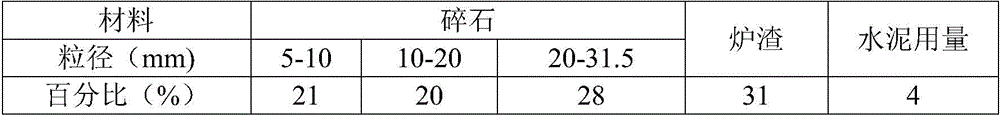

Furnace slag water-stable base material and preparation method thereof

InactiveCN105731920AImprove mechanical propertiesStable structureSolid waste managementMineral SourcesSlag

The invention discloses a furnace slag water-stable base material and a preparation method thereof. The furnace slag water-stable base material is formed by mixing a dry material and water. The dry material comprises the following components in percentage by weight: 3-5% of cement, 20-35% of furnace slag and 65-75% of macadam. The water accounts for 3.5-5.5 wt% of the dry material. The furnace slag is used instead of fine aggregate, thereby reducing the probability of cracking caused by temperature shrinkage when the cement content and water-stable base are reduced. The solid waste is used as the fine aggregate in the water-stable base material, thereby changing wastes into valuable substances, saving the waste piling site and saving the mineral resources of macadam production. The furnace slag material is pretreated, so that the heavy metal content and leaching toxicity are lower than the standard values. The furnace slag water-stable base material is applicable to the water-stable base with higher economic value, and lowers the engineering cost.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Seashore building cement resisting strong wind and big waves

The invention discloses seashore building cement resisting strong wind and big waves. The seashore building cement is prepared from the following raw materials in parts by weight: 60-80 parts of slag, 1-30 parts of sulphoaluminate cement clinker, 5-10 parts of silicon powder, 0.03-0.05 part of composite activating agent, 2-4 parts of early strength agent, 1-3 parts of water reducer, 0.005-0.007 part of air entraining agent, and 0.3-0.5 part of retarder. The production method comprises the steps of: respectively crushing, milling and homogenizing the slag, sulphoaluminate cement clinker, silicon powder, composite activating agent, and early strength agent, then batching, mixing and homogenizing according to the ratio, then adding the water reducer, air entraining agent, and retarder, and mixing and homogenizing to obtain a product. The green and ecological cement resisting strong wind and big waves also has good characteristics of high strength, seawater erosion resistance, seawater rushing resistance and the like besides of the performance of common cement, and is especially suitable for the engineering of ports and docks resisting wind and big wave impact and other erosion medium corrosion.

Owner:广西云燕特种水泥建材有限公司

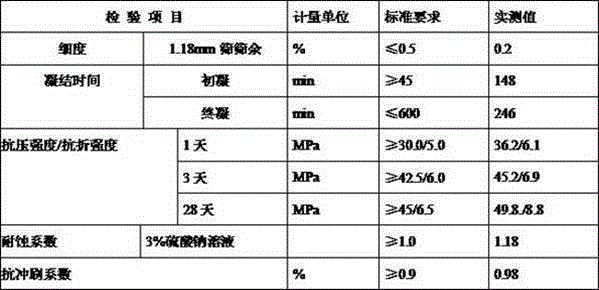

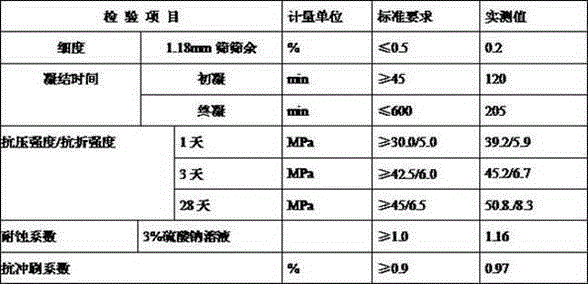

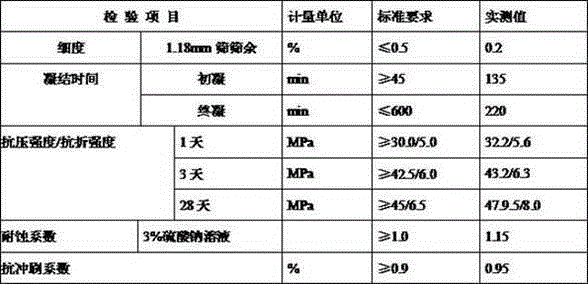

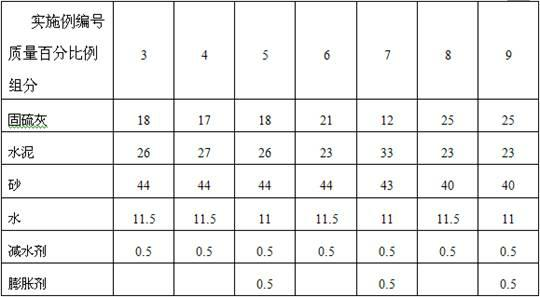

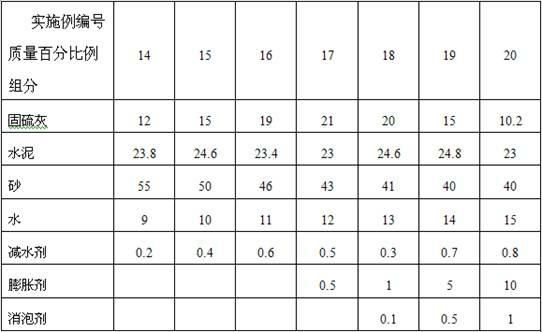

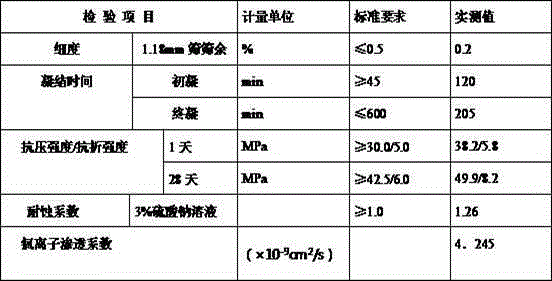

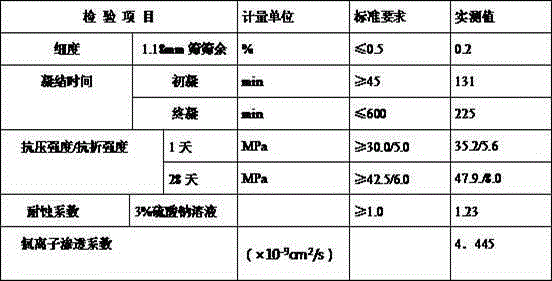

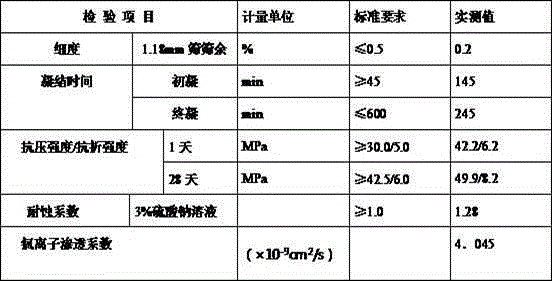

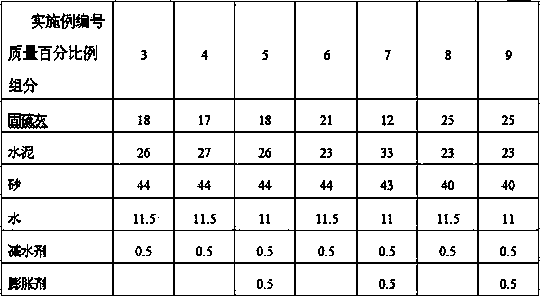

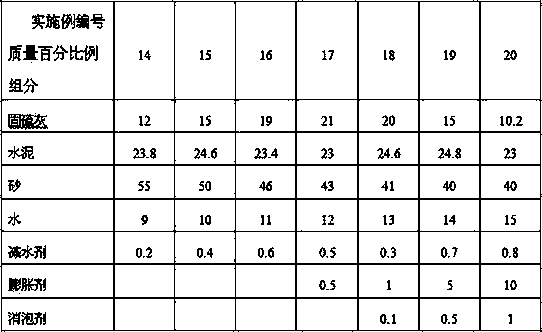

Grouting material containing circulating fluidized bed fuel coal solid sulfur ash

The invention discloses a grouting material containing circulating fluidized bed fuel coal solid sulfur ash. The grouting material containing the circulating fluidized bed fuel coal solid sulfur ash is characterized by comprising the following components in percentage by mass: 10 to 25 percent of solid sulfur ash, 23 to 35 percent of cement, 40 to 55 percent of sand, 0.2 to 0.8 percent of water-reducing agent, 9 to 15 percent of water, 0 to 10 percent of expanding agent and 0 to 1 percent of defoaming agent. The grouting material adopts industrial waste solid sulfur ash as an admixture, utilizes the cinerite activity and the expanding performance of the solid sulfur ash, changes waste into treasure, is low in cost, reduces environmental pollutions, and has a simple production process, low energy consumption, excellent product performance and high practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for producing high-salinity maritime work cement through mineral waste residue waste materials

The invention discloses a method for producing high-salinity maritime work cement through mineral waste residue waste materials. The high-salinity maritime work cement is prepared from, by weight, 30-40 parts of mineral waste residues, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of composite activating agents, 2-4 parts of early strength agents, 0.3-0.5 part of water reducing agents, 0.005-0.007 part of air entraining agents and 0.3-0.5 part of retarder. The method for producing the high-salinity maritime work cement comprises the steps that the mineral waste residue waste materials, the sulphate aluminum clinker, the composite activating agents and the early strength agents are smashed, ground into powder and homogenized respectively and then dosed, mixed and homogenized according to proportions, then the water reducing agents, the air entraining agents and the retarder are added, mixed and homogenized, and the product is obtained. The high-salinity maritime work cement has the performance of common cement, further has the excellent characters of early-stage hardness resisting, long-term corrosion resistance, retardation progressive increasing and the like, and is especially suitable for ports, wharfs and other engineering which are corroded by corrosive media.

Owner:广西云燕特种水泥建材有限公司

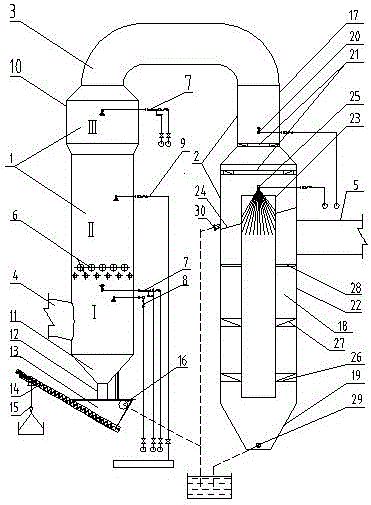

Dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in metallurgical slag treatment process

InactiveCN106731403AHigh efficiency of dust removal and purificationAchieve Energy Efficiency UpgradesCombination devicesGas treatmentEnvironmental resistanceMetallurgical slag

The invention relates to a dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in a metallurgical slag treatment process. The apparatus comprises a tower for spraying, sprinkling and washing and a downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow; an outlet at the upper end of the tower for spraying, sprinkling and washing and an inlet at the upper end of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow are connected by a connection flue; a sidewall at the lower end of the tower for spraying, sprinkling and washing is provided with a flue gas inlet pipeline; a sidewall of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow is provided with a flue gas outlet pipeline; the tower for spraying, sprinkling and washing employs a wet type multilayer gas-liquid countercurrent contact mode, and the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow employs a gas-liquid current contact mode. The dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in the metallurgical slag treatment process is adapted to characteristics of high temperature, high moisture and high viscosity flue gas, and realizes ultra-low flue dust emission concentration in a low energy consumption condition, in order to satisfy more strict environmental protection emission requirements of pollution treatment.

Owner:SHANGHAI BAOSTEEL ENERGY TECH +1

High-temperature calcination production method of industrial byproduct gypsum

The invention discloses a high-temperature calcination method of industrial byproduct gypsum, and belongs to the field of building materials. The method includes the following steps: 1. heating the industrial byproduct gypsum by flame; 2. heat preservation; 3. humidification reduction. The method has the advantages of optimizing the calcining process of the industrial byproduct gypsum to obtain the building gypsum with good strength and comprehensive performance, and overcoming the defects of the gypsum produced by the existing method.

Owner:ZHENGZHOU SUNDY BUILDING TECH

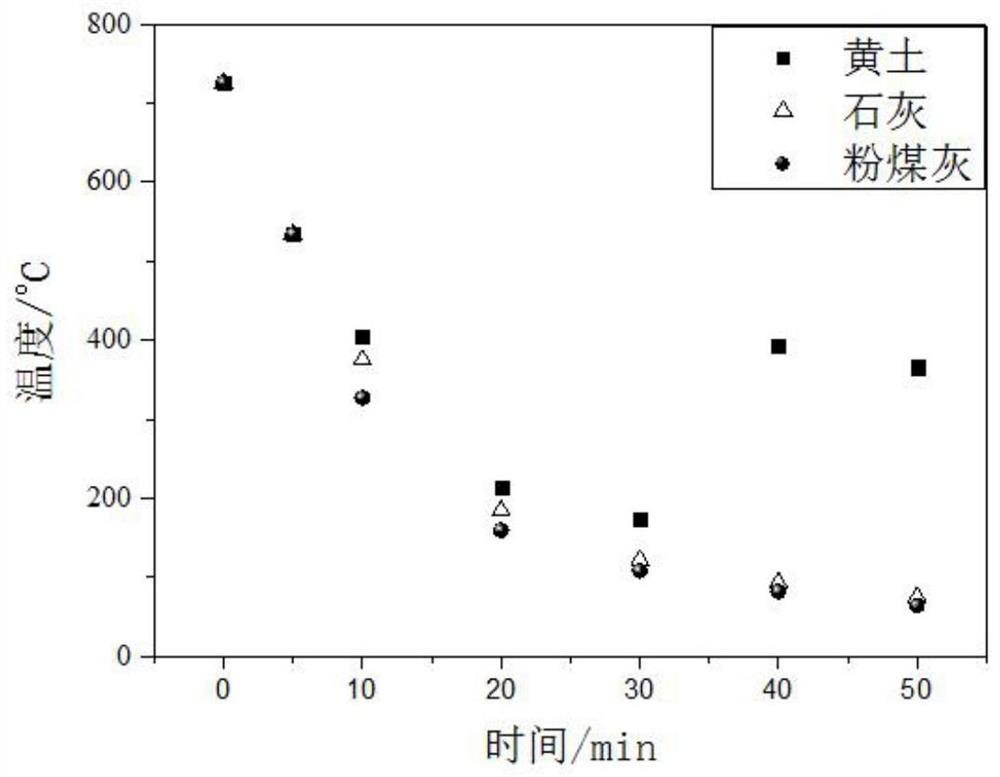

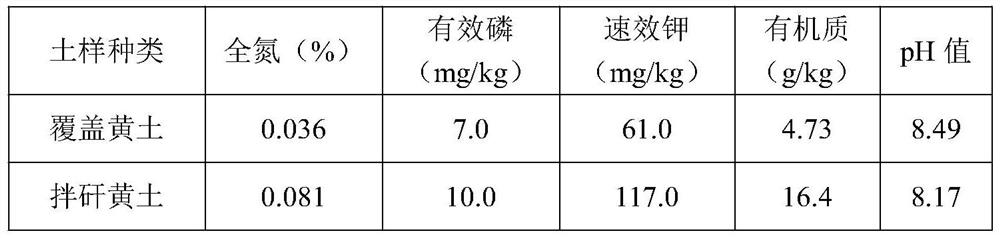

Coal gangue hill fire extinguishment and reburning prevention method using coal-based solid waste

PendingCN112870584AReduce dosageImprove soil structureFire rescueBoring toolsCoal gangueMining engineering

The invention relates to the technical field of coal gangue hill fire extinguishment, in particular to a coal gangue hill fire extinguishment and reburning prevention method using coal-based solid waste. The method comprises the following steps: injecting solid waste-based fire extinguishment slurry into a spontaneous combustion coal gangue hill by using a grouting pump, filling gaps with the slurry, isolating oxygen and blocking gangue combustion in a deep area; and pouring and paving a solid waste-based gelling sealing material with the thickness of 5-15cm on the surface of the coal gangue hill subjected to fire extinguishing treatment, and after natural curing and curing, and spraying an elastic sealing material in each block gap to form a rigid-flexible combined sealing isolation layer to completely cover the coal gangue hill and isolate an air inlet path, so that air in the gangue is exhausted to prevent reburning. Gangue-mixed loess is adopted, so that the loess consumption is reduced, and the soil structure is improved. The coal gangue is beneficial to plant growth. According to the coal gangue hill fire extinguishment and reburning prevention method using the coal-based solid waste, oxygen can be effectively prevented from entering the coal gangue hill, the effects of filling, leaking stoppage and fire prevention and extinguishing are achieved, pollution of the spontaneous combustion coal gangue hill to the environment is reduced, and comprehensive treatment of the regional solid waste is achieved.

Owner:SHANXI UNIV

No-baking light foamed heat insulating and sound isolating material and its production process

InactiveCN1887783AHigh potential activityHydraulically hardSolid waste managementCeramicwareHigh activityUltimate tensile strength

The present invention is one kind of no-baking light foamed heat insulating and sound isolating material and its production process. The no-baking light foamed heat insulating and sound isolating material has high activity fly ash, which is produced based on one other patent of the present inventor, as basic material and some other components. It has high water resistance, high strength, high fireproof performance and high stability.

Owner:郑东风

Lime-metakaolin modified soil and application thereof

The invention discloses lime-metakaolin modified soil and application thereof, and relates to the technical field of soil architecture site restoration. The lime-metakaolin modified soil provided by the invention is prepared from the following components in percentage by mass: 8-12% of quicklime powder, 4-12% of metakaolin, and the balance of a soil material. The lime-metakaolin modified soil provided by the invention is a natural inorganic material, the good compatibility of traditional lime mortar is retained, the hydraulicity of hydraulic lime is achieved, after curing for 28 days, a compressive strength value of the lime-metakaolin modified soil can meet the compressive strength class requirements for natural hydraulic lime NHL5, the color change is not obvious, the cost is low, the economical efficiency and environmental protection are achieved, and the significant advantages are achieved in application of restoration and reinforcement of soil architecture sites.

Owner:ZHONGYUAN ENGINEERING COLLEGE

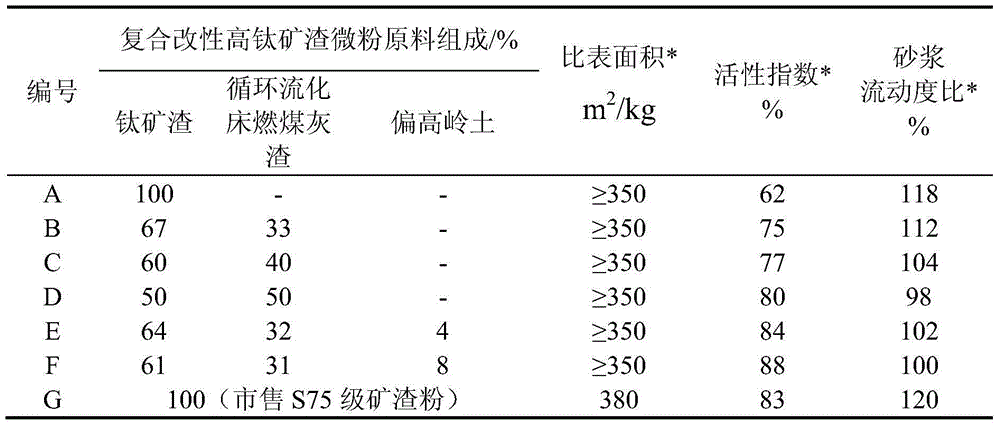

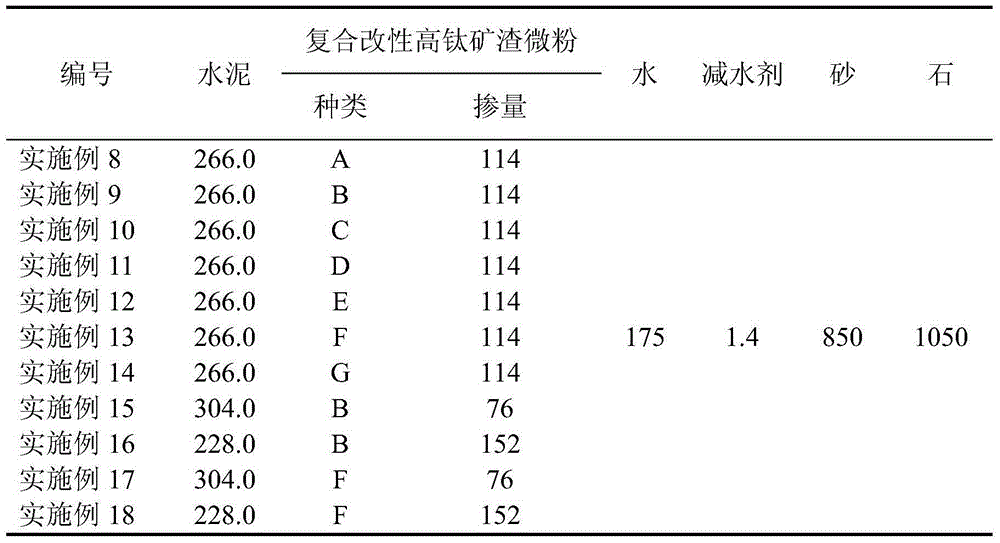

Composite modified high titanium slag micropowder used for concrete and concrete preparation method

ActiveCN104402280AImprove performanceLarge increase in late strengthSolid waste managementFluidized bedEconomic benefits

The invention discloses composite modified high titanium slag micropowder used for concrete, and the composite modified high titanium slag micropowder is characterized by being prepared by mixing 50%-67% by weight of high titanium slag, 31%-50% by weight of circulating fluidized bed fire coal ash and 0%-8% by weight of metakaolin. The concrete is prepared by mixing the composite modified high titanium slag micropowder with cement, sand, stone, water and a water reducing agent by stirring, molding and curing. The composite modified high titanium slag micropowder can use a large amount of the industrial solid waste high titanium slag and the circulating fluidized bed fire coal ash; the concrete performance is better than that of single doped S75 grade granulated blast furnace slag powder concrete. By adopting the composite modified high titanium slag micropowder, industrial solid waste is extensively used, the preparation method is simple, cost is low, the composite modified high titanium slag micropowder is especially suitable for regions in which a large number of high titanium slag and circulating fluidized bed fire coal ash are simultaneously discharged, and has obvious economic benefits, broad market prospects and strong practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Copper-based low-temperature shift catalyst and preparation method thereof

PendingCN112206763AReduce churnStable structureHydrogenHydrogen/synthetic gas productionAlkaline earth metalPtru catalyst

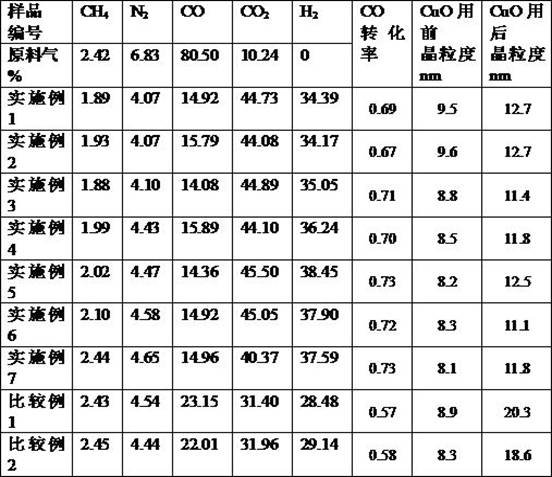

The invention relates to a copper-based low-temperature shift catalyst and a preparation method thereof, and aims to solve the problem of fusion growth of copper microcrystals of the existing copper-based catalyst under high load. By changing the formula and the preparation method of the copper-based low-temperature shift catalyst, the CO conversion depth advantage of the copper-based low-temperature shift catalyst is exerted, the dispersity of copper crystallites in the catalyst is improved, the copper crystallites are prevented from melting and growing up under high load, and the copper-based low-temperature shift catalyst has higher conversion rate, structural stability and service life under high-carbon low-temperature shift reaction. The catalyst disclosed by the invention mainly comprises CuO, ZnO, Al2O3, SiO2, alkali metal and alkaline-earth metal, is suitable for an atmosphere with CO content of 50% or more in feed gas, and is also suitable for deep conversion of CO in an atmosphere with CO content of 10% or less in the feed gas.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

Preparation method of natural brucite fiber modified lime-metakaolin composite mortar

The invention discloses a preparation method of natural brucite fiber modified lime-metakaolin composite mortar. The preparation method specifically comprises natural brucite fiber pretreatment and natural brucite fiber modified L-MK mortar, a lime-metakaolin cementing material is an inorganic cementing material having hydraulicity and prepared by mixing slaked lime and active metakaolin accordingto a certain ratio; the metakaolin is a main active component in the L-MK cementing material; therefore, the L-MK cementing material not only retains good compatibility of lime and an ancient building matrix, but also has hydraulicity of cement; the L-MK cementing material has the non-negligible advantage in the repairing work of masonry and rock soil ancient buildings; in addition, the raw materials limestone and kaolin are rich in resource, convenient to process, low in price and low in calcination temperature, CO2 in the atmospheric environment can be absorbed in the hardening process, andthus the L-MK cementing material is a low-energy-consumption environment-friendly material.

Owner:河北地质大学

Preparation method of alkali-activated seafloor sediment cementing material

The invention relates to a cementing material and a preparation method thereof, in particular to a preparation method of an alkali-activated seafloor sediment cementing material, and aims to solve theproblems of slow construction speed and high transportation cost caused by transportation of building materials from the inland in marine engineering construction. The alkali-activated seafloor sediment cementing material is prepared from seafloor sediment and an alkali-activator. The preparation method includes: taking seafloor sediment, and using shell or coral to adjust the mass ratio of calcium oxide and silicon oxide in the seafloor sediment; and carrying out smelting treatment, water quenching treatment, crushing, drying, levigating and sieving treatment to obtain activated seafloor sediment powder; and mixing the activated seafloor sediment powder with the alkali-activator to obtain the alkali-activated seafloor sediment cementing material. The cementing material provided by the invention has hydraulicity, and has the characteristics of rapid hardening, high strength, compact internal structure and good impermeability. The materials needed for preparation are all obtained locally, thus avoiding the problems of high transportation cost and long transportation time. The method provided by the invention is suitable for preparation of cementing materials.

Owner:HARBIN INST OF TECH

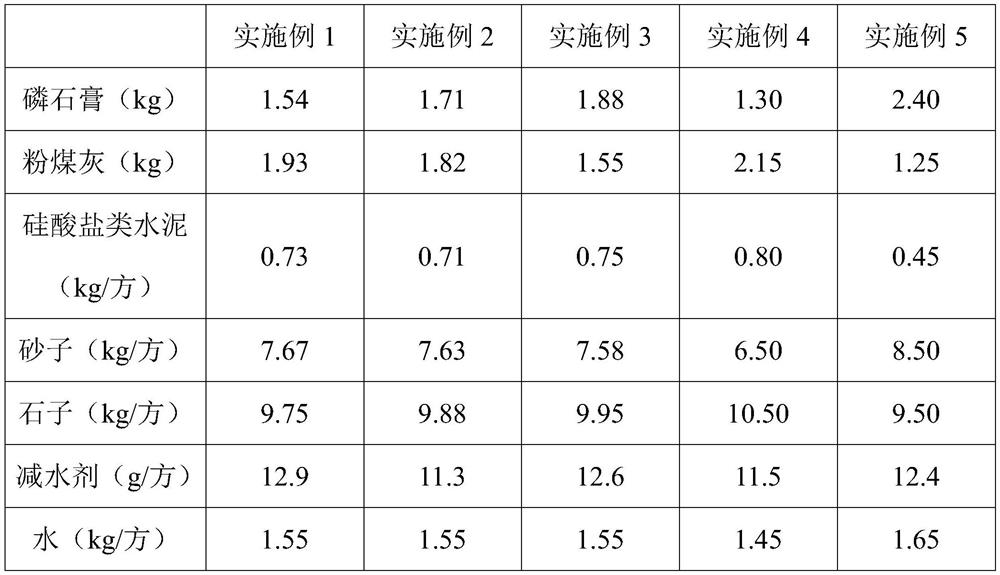

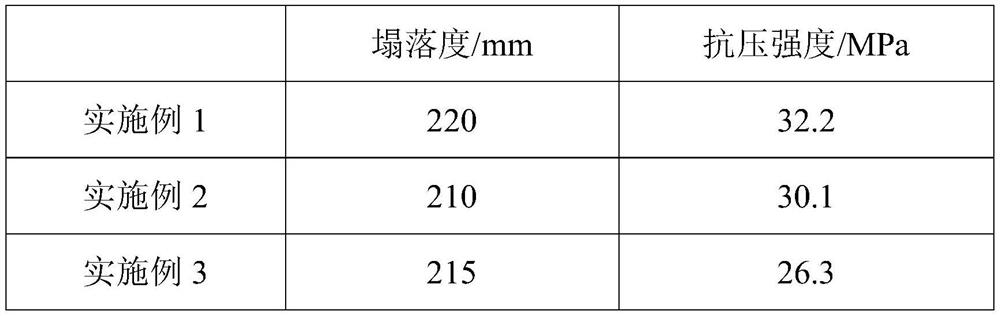

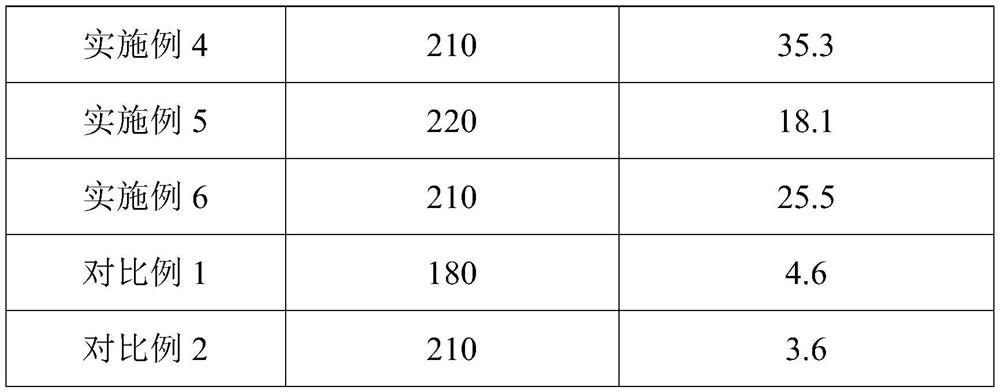

Concrete product containing phosphogypsum fly ash cement and preparation method thereof

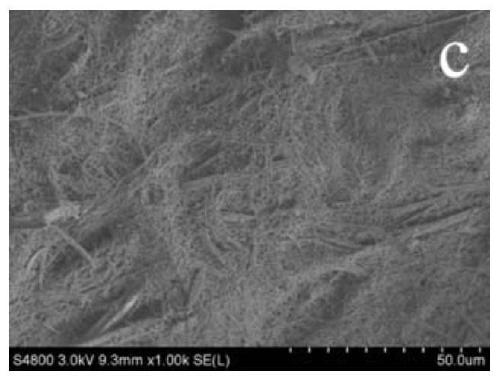

PendingCN113735545AHydraulically hardHigh strengthSolid waste managementCeramic shaping apparatusProcess engineeringWet grinding

The invention provides a concrete product containing phosphogypsum fly ash cement and a preparation method thereof. The concrete product is prepared from the following raw materials in parts by weight: 130 to 240 parts of phosphogypsum, 125 to 215 parts of fly ash, 45 to 80 parts of silicate cement, 650 to 850 parts of sand, 950 to 1050 parts of stones and 145 to 165 parts of water. According to the concrete product, process waste resources are utilized, the cement consumption is reduced, and environmental protection is facilitated. The preparation method comprises the following steps: adding water into ardealite and part of silicate cement, performing wet grinding to obtain ardealite slurry, filtering and concentrating to obtain ardealite mud; mixing and stirring the ardealite mud, the fly ash, the rest silicate cement, the sand, the stones and the water, pressing or pouring to form a concrete product; and finally, performing product maintenance treatment. According to the preparation method, calcination is not needed, the concrete product is produced through direct wet grinding, the concrete strength is improved, and the setting time is shortened.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Gypsum-based sealing material for splicing joints of prefabricated building components and its application

ActiveCN103496936BEasy constructionImprove plasticityBuilding constructionsResource utilizationEther

The invention relates to an assembly type building component joint gypsum base sealing material and application thereof. The assembly type building component joint gypsum base sealing material comprises, by weight, 100 parts of waste gypsum, 20-200 parts of active admixture, 0.01-10 parts of water reducer, 0.1-50 parts of excitant, 0-10 parts of thickening control agent, 0-30 parts of binder, 0-10 parts of air entraining agent, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of water repellent, 0-5 parts of starch ether, 0-10 parts of thixotropic lubricant, 0-150 parts of powder filler and 0-300 parts of aggregate, and can be applied to joint sealing after being mixed with water uniformly. Compared with the prior art, the assembly type building component joint gypsum base sealing material has the advantages of convenience in use, good filling ability, high binding power, durability, low cost and the like. In the sealing material, much industrial waste gypsum is used as gelatinization materials, so that performance of sealing mortar can be improved, material cost is reduced, pollution control and emission reduction are facilitated, and a new way for resource utilization of the industrial waste gypsum is provided.

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

Anti-freezing concrete and preparation method thereof

InactiveCN112374850AImprove impermeabilityImprove frost resistanceSolid waste managementPortland cementWater reducer

The invention relates to the technical field of concrete, in particular to anti-freezing concrete and a preparation method thereof. The anti-freezing concrete is prepared from the following componentsin parts by weight: 99-164 parts of aggregate, 115-154 parts of Portland cement, 44-61 parts of water, 1.1-1.5 parts of a water reducing agent, 8-17 parts of silicon powder and 12-15 parts of gypsum.According to the anti-freezing concrete, the silicon powder is added as an admixture, the silicon powder and cement can be hydrated to generate a hydraulic cementing material, and the silicon powderhas rheological property and can fill micro-cracks in the concrete, so that the pore structure in rock-like mass is improved, the bonding effect between internal particles and the cementing material is enhanced, and the impermeability and the frost resistance of the concrete are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

No-baking light foamed heat insulating and sound isolating material and its production process

InactiveCN100384771CHigh potential activityHydraulically hardSolid waste managementCeramicwareHigh activityUltimate tensile strength

The present invention is one kind of no-baking light foamed heat insulating and sound isolating material and its production process. The no-baking light foamed heat insulating and sound isolating material has high activity fly ash, which is produced based on one other patent of the present inventor, as basic material and some other components. It has high water resistance, high strength, high fireproof performance and high stability.

Owner:郑东风

Grouting material containing circulating fluidized bed fuel coal solid sulfur ash

The invention discloses a grouting material containing circulating fluidized bed fuel coal solid sulfur ash. The grouting material containing the circulating fluidized bed fuel coal solid sulfur ash is characterized by comprising the following components in percentage by mass: 10 to 25 percent of solid sulfur ash, 23 to 35 percent of cement, 40 to 55 percent of sand, 0.2 to 0.8 percent of water-reducing agent, 9 to 15 percent of water, 0 to 10 percent of expanding agent and 0 to 1 percent of defoaming agent. The grouting material adopts industrial waste solid sulfur ash as an admixture, utilizes the cinerite activity and the expanding performance of the solid sulfur ash, changes waste into treasure, is low in cost, reduces environmental pollutions, and has a simple production process, low energy consumption, excellent product performance and high practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of production method of marine cement block

The invention discloses a production method of a marine engineering cement block. The marine engineering cement block comprises the following raw materials in parts by weight: 30-80 parts of slag, 10-50 parts of a sulphoaluminate cement clinker, 0.03-0.05 part of an accelerating activating admixture, 2-4 parts of an early strength agent, 0.3-0.5 part of a water reducing agent, 0.005-0.007 part of an air entraining agent and 0.3-0.5 part of a retarder. The production method comprises the following steps: respectively crushing, milling and homogenizing the slag waste, the sulphoaluminate cement clinker, the accelerating activating admixture and the early strength agent; and mixing and homogenizing ingredients at the ratio, adding the water reducing agent, the air entraining agent and the retarder for mixing, homogenizing and molding to obtain the product. The marine engineering cement block disclosed by the invention also has excellent characteristics of high strength, seawater washing resistance, early hardening resistance, long-term erosion resistance and the like besides of properties of an ordinary cement block, and is especially suitable for ports, wharfs and other erosion medium-corroded engineering.

Owner:广西云燕特种水泥建材有限公司

A water-resistant thermal insulation glass magnesium board and its preparation method

ActiveCN104744011BHas rapid hardening and early strength propertiesHydraulically hardSolid waste managementSlagThermal insulation

The invention discloses a waterproof thermal-insulation glass magnesium board and a preparation method thereof and belongs to the technical field of preparation of new building materials from non-metallic minerals. The glass magnesium board is mainly prepared from the following raw materials in parts by weight: 10-18 parts of light calcined magnesia, 15-25 parts of magnesium chloride hexahydrate, 20-25 parts of water, 5-10 parts of superfine slag powder, 0.5-2 parts of hydrophobic aerogel, 0.3-0.6 part of a surface modifier and 0.25-0.5 part of a waterproof modifier. The waterproof thermal insulation glass magnesium board has good water resistance, hardly produces halogenide, does not warp or deform and is light in weight, thermal insulation performance is greatly improved, and quality defects of an existing glass magnesium board are overcome, and application range of the glass magnesium board is expanded.

Owner:南京格瑞恩斯新材料科技有限公司

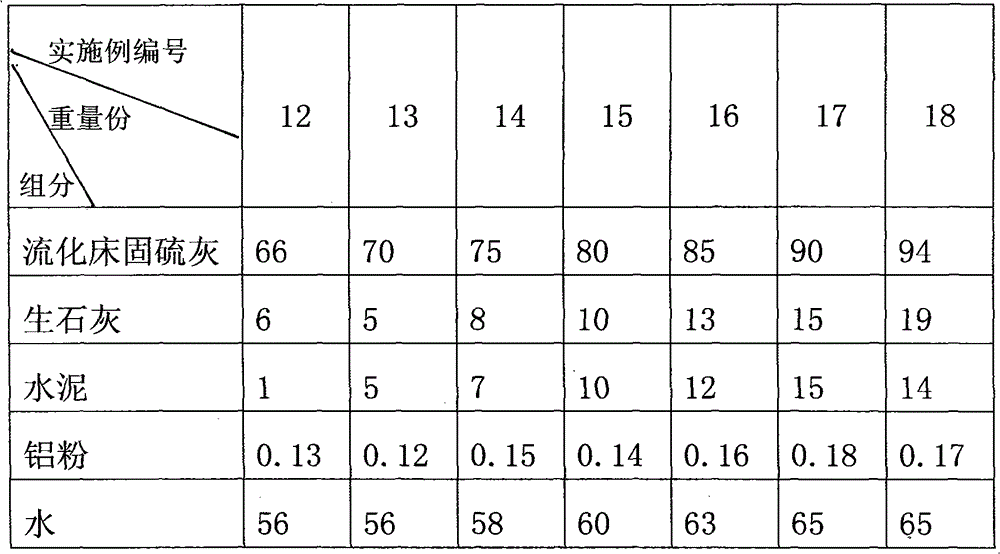

Circulating fluidized bed sulfur fixation ash aerated concrete and preparation method thereof

InactiveCN101863678BHigh strengthPozzolanic activitySolid waste managementCeramic shaping apparatusMaterials preparationSulfur

Owner:SOUTHWEAT UNIV OF SCI & TECH

Flame-retardant fiber board and manufacturing method thereof

InactiveCN101602224BLow priceMaterials are readily availableWood working apparatusGlass/slag layered productsFiberPolymer science

The invention relates to a flame-retardant fiber board and a manufacturing method thereof. The flame-retardant fiber board is prepared from the following raw materials in portion by weight: 80 to 120 portions of fiber, 80 to 120 portions of magnesia, 80 to 200 portions of water solution of magnesium sulfate, 5 to 30 portions of active silica, 0.5 to 2 portions of organosilicon waterproof agent, and 0.5 to 1.5 portions of plasticizer. The manufacturing method comprises the steps: 1) preparing the fiber, namely cleaning and drying crop straws, wood branches or wood processing residual materials, and then obtaining the fiber through the crushing by a crushing machine; 2) preparing an inorganic adhesive, namely mixing the magnesia, the water solution of the magnesium sulfate, the active silica, the organosilicon waterproof agent and the plasticizer, and stirring the mixture to obtain the inorganic adhesive; 3) mixing the fiber and the inorganic adhesive prepared through the step 1 and thestep 2, stirring the mixture, and paving the mixture after the screening by a screening machine; 4) paving a reinforcing network on the upper and lower surfaces of a paved slab; and 5) finally performing hot pressing on the board paved with the reinforcing network for 10 to 25 minutes at a temperature of between 100 and 110 DEG C at a pressure of between 12 and 30MPa to obtain the flame-retardantfiber board. The flame-retardant fiber board has broad application field.

Owner:湖南迪普环保建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com