Gypsum-based sealing material for splicing joints of prefabricated building components and its application

A technology for sealing materials and building components, applied in building structures, buildings, etc., can solve the problems of large slurry resistance, loss of sealing slurry fluidity, and high requirements for construction equipment, achieving long operation time, good construction performance, and overcoming cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The gypsum-based sealing material for the splicing joints of prefabricated building components adopts the following components:

[0046] Waste gypsum (dihydrate desulfurized gypsum) 100, active admixture (S95 slag powder) 150, water reducing agent (polycarboxylate superplasticizer) 0.5, activator (sodium metasilicate) 5, binder (vinyl acetate Ester / ethylene copolymer rubber powder) 8, plasticizer (lignocellulose) 2.0, plasticizer (diatomaceous earth) 20, starch ether 1.0, water repellent (silicone powder) 0.5, thixotropic lubricant 0.8, bone Material (quartz sand 10-20 mesh) 80, aggregate (quartz sand 30-60 mesh) 50, aggregate (hydrophobic expanded perlite 1-3mm) 15.

[0047] Preparation method: Weigh various raw materials according to the formula, and add aggregate (quartz sand, expanded perlite), waste gypsum, active admixture (slag powder), and water reducer (polycarboxylate water reducer) to the mixer in sequence , activator (sodium metasilicate), binder (vinyl ace...

Embodiment 2

[0053] The gypsum-based sealing material for the splicing joints of prefabricated building components adopts the following components:

[0054] Waste gypsum (semi-hydrated desulfurization gypsum) 100, active admixture (S95 slag powder) 80, active admixture (silica fume) 10, water reducing agent (naphthalene series superplasticizer) 1.0, activator (calcium hydroxide ) 25, activator (calcium chloride) 5.0, coagulant (sodium polyphosphate) 0.2, binder (redispersible latex powder) 6, air-entraining agent (sodium lauryl sulfate) 0.3, plastic Agent (hydroxyethyl cellulose ether) 2.0, plasticizer (bentonite) 10, starch ether 0.8, thixotropic lubricant 1.0, powdery filler (talc powder) 50, aggregate (quartz sand 10-20 mesh) 30, Aggregate (quartz sand 30-60 mesh) 30, aggregate (vitrified beads) 30.

[0055] Preparation:

[0056] Desulfurized gypsum is pre-dried at 40-60°C, then calcined at 140-180°C to obtain hemihydrate desulfurized gypsum, which is ground and passed through a 200-m...

Embodiment 3

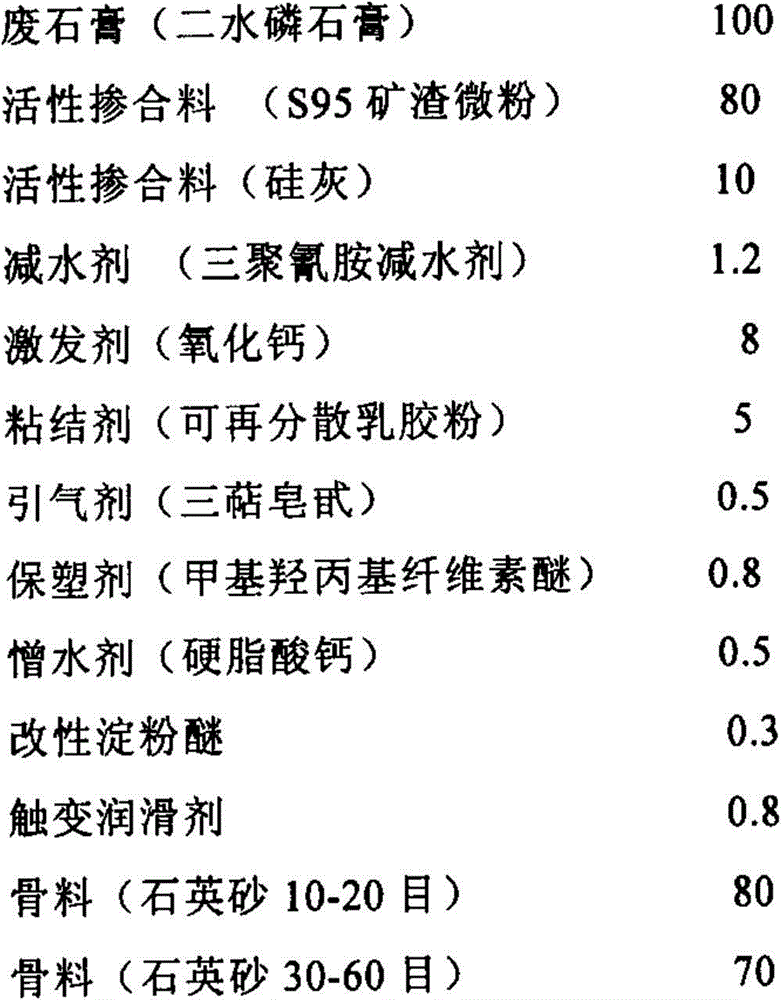

[0061] The gypsum-based sealing material for the splicing joints of prefabricated building components adopts the following components:

[0062]

[0063] Preparation:

[0064] 1. Phosphogypsum is pre-dried at 40-60°C, ground and passed through a 200-mesh sieve for use;

[0065] 2. Weigh various raw materials according to the formula, add aggregate (quartz sand), waste gypsum (phosphogypsum dihydrate), active admixture (slag powder, silica fume), water reducing agent (melamine water reducing agent), activator (calcium oxide), binder (ethylene / vinyl acetate copolymer latex powder), air-entraining agent (triterpene saponin), plastic retainer (methyl hydroxypropyl cellulose ether), hydrophobic Water agent (calcium stearate), modified starch ether and thixotropic lubricant, fully stirred evenly, packaged to form a product.

[0066] The application process is the same as before, wherein the amount of water added is 22% of the weight of the sealing material, and the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com