A water-resistant thermal insulation glass magnesium board and its preparation method

A technology of glass magnesium board and magnesium chloride hexahydrate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of returning halogen and frost, restricting development, reducing strength, etc. Ease of operation and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

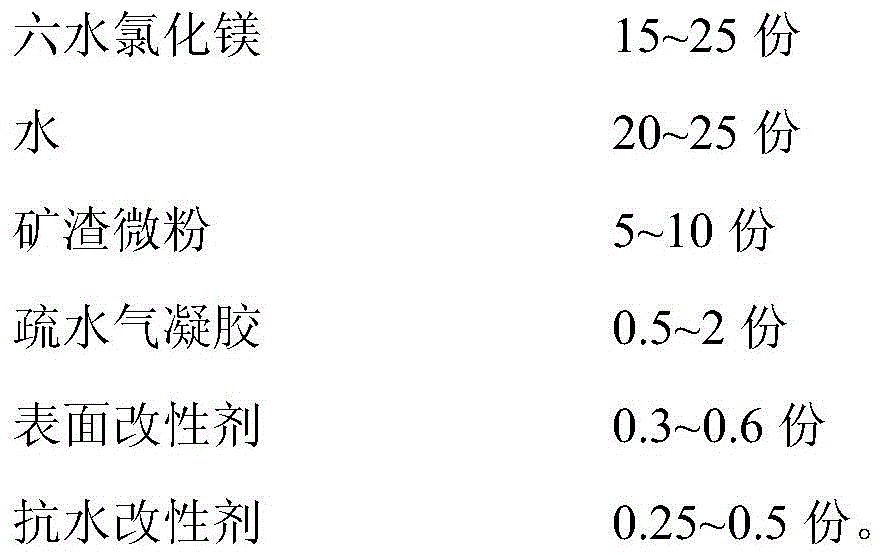

Method used

Image

Examples

Embodiment 1

[0055] 15 parts by weight of light-burned magnesium oxide, 20 parts by weight of magnesium chloride hexahydrate, 8 parts by weight of wood chips, 20 parts by weight of water, 6 parts by weight of slag micropowder, 1.5 parts by weight of hydrophobic airgel particles, surface modifier silane coupling agent KH- 550 0.5 parts by weight, phosphoric acid 0.4 parts by weight.

[0056] The preparation method of the above-mentioned water-resistant thermal insulation glass magnesium board is carried out according to the following steps:

[0057] A, 15 parts by weight of light-burned magnesia, 6 parts by weight of slag micropowder (specific surface area ≥ 400m 2 / kg of blast furnace slag), 8 parts by weight of wood chips and 1.5 parts by weight of hydrophobic airgel particles are added to the mixer, stirred for 5min, and mixed uniformly;

[0058] B. Add 20 parts by weight of water to 20 parts by weight of magnesium chloride hexahydrate, stir evenly, and treat that magnesium chloride hex...

Embodiment 2

[0065] 18 parts by weight of light-burned magnesium oxide, 8 parts by weight of slag fine powder, 8 parts by weight of wood chips, 2 parts by weight of hydrophobic airgel particles, 23 parts by weight of magnesium chloride hexahydrate, 23 parts by weight of water, surface modifier silane coupling agent KH- 570 0.6 parts by weight, aluminum phosphate 0.5 parts by weight.

[0066] The preparation method of the above-mentioned water-resistant thermal insulation glass magnesium board is carried out according to the following steps:

[0067] A, 18 parts by weight of light-burned magnesia, 8 parts by weight of slag micropowder (specific surface area ≥ 400m 2 / kg of blast furnace slag), 8 parts by weight of wood chips and 2 parts by weight of hydrophobic airgel particles are added to the mixer, stirred for 5min, and mixed uniformly;

[0068] B, add 23 parts by weight of water in 23 parts by weight of magnesium chloride hexahydrate, stir evenly, treat that magnesium chloride hexahydr...

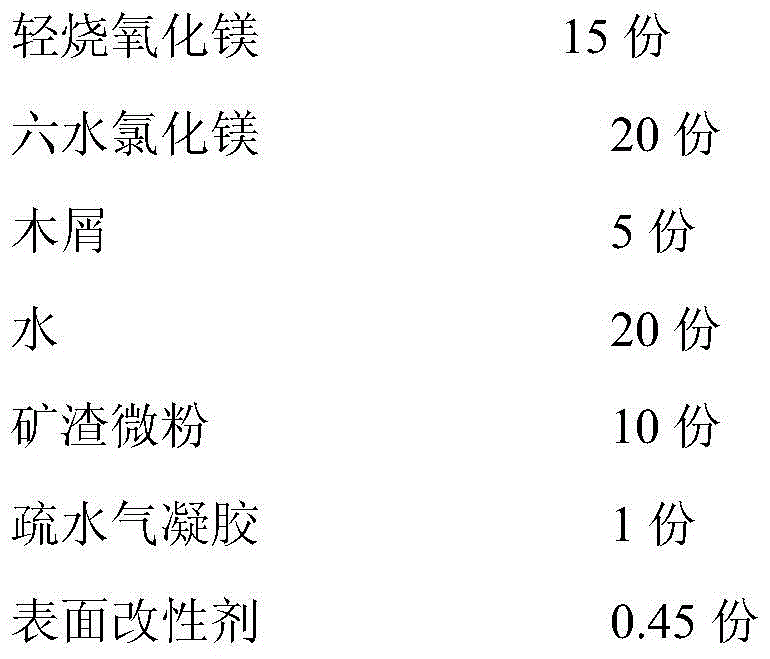

Embodiment 3

[0075] 15 parts by weight of light-burned magnesium oxide, 5 parts by weight of slag fine powder, 7 parts by weight of wood chips, 2 parts by weight of hydrophobic airgel particles, 20 parts by weight of magnesium chloride hexahydrate, 20 parts by weight of water, surface modifier titanate coupling agent 0.6 parts by weight of NDZ-101, and 0.5 parts by weight of sodium hexapolyphosphate.

[0076] The preparation method of the above-mentioned water-resistant thermal insulation glass magnesium board is carried out according to the following steps:

[0077] A, 15 parts by weight of light-burned magnesia, 5 parts by weight of slag micropowder (specific surface area ≥ 400m 2 / kg of blast furnace slag), 7 parts by weight of wood chips and 2 parts by weight of hydrophobic airgel particles are added to the mixer, stirred for 5min, and mixed uniformly;

[0078] B. Add 20 parts by weight of water to 20 parts by weight of magnesium chloride hexahydrate, stir evenly, and treat that magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com