Flame-retardant glass magnesium board and production process thereof

A production process and technology of glass magnesium board, which is applied in the field of building decoration materials, can solve the problems of flexural strength, impact strength, shrinkage rate, wet expansion rate, screw-holding force, non-combustibility, and it is difficult to meet the requirements of national or industry standards at the same time, Insufficient magnesium, rapid condensation, limiting the use of glass magnesium board and other problems, to achieve the effect of reducing density and thermal conductivity, light weight, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

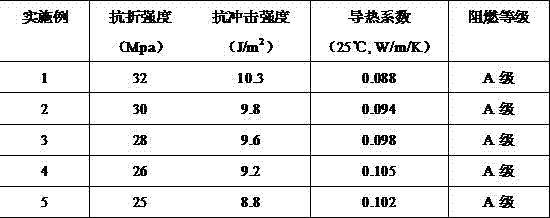

Examples

Embodiment 1

[0023] A flame-retardant glass magnesium board, comprising the following raw materials in parts by weight:

[0024] 62 parts of lightly burned magnesium oxide;

[0025] 35 parts of anhydrous magnesium sulfate;

[0026] 6 parts of magnesium chloride hexahydrate;

[0027] 10 parts of forsterite powder;

[0028] 2 parts of decabromodiphenyl ether;

[0029] straw 28 parts;

[0030] 3.5 parts of silane coupling agent;

[0031] 0.9 part of ammonium zirconium carbonate;

[0032] 52 parts of water.

[0033] The production process of the above-mentioned flame-retardant glass magnesium board comprises the following steps:

[0034] (1) Add light-burned magnesia, anhydrous magnesium sulfate, and forsterite powder into a blender and mix evenly, and then grind into powder by a mill to obtain a mixture a;

[0035] (2) Mix magnesium chloride hexahydrate with water, stir at 30-40°C for 5-10 minutes, add mixed material a, heat up to 50-60°C, then add decabromodiphenyl ether, straw, sila...

Embodiment 2

[0039] A flame-retardant glass magnesium board, comprising the following raw materials in parts by weight:

[0040] 68 parts of lightly burned magnesium oxide;

[0041] 35 parts of anhydrous magnesium sulfate;

[0042] 6 parts of magnesium chloride hexahydrate;

[0043] 10 parts of forsterite powder;

[0044] 2 parts of decabromodiphenyl ether;

[0045] 30 parts of slag fine powder;

[0046] 3.6 parts of titanate coupling agent;

[0047] 1.2 parts of styrenated phenol;

[0048] 56 parts of water.

[0049] The production process of the above-mentioned flame-retardant glass magnesium board comprises the following steps:

[0050] (1) Add light-burned magnesia, anhydrous magnesium sulfate, and forsterite powder into a blender and mix evenly, and then grind into powder by a mill to obtain a mixture a;

[0051] (2) Mix magnesium chloride hexahydrate with water, stir at 30-40°C for 5-10 minutes, add mixed material a, heat up to 50-60°C, then add decabromodiphenyl ether, slag ...

Embodiment 3

[0055] A flame-retardant glass magnesium board, comprising the following raw materials in parts by weight:

[0056] 75 parts of lightly burned magnesium oxide;

[0057] 36 parts of anhydrous magnesium sulfate;

[0058] 5 parts of magnesium chloride hexahydrate;

[0059] 12 parts of forsterite powder;

[0060] 3 parts of decabromodiphenyl ether;

[0061] 30 parts of expanded perlite;

[0062] 4.6 parts of silane coupling agent;

[0063] 1.5 parts of ammonium zirconium carbonate;

[0064] 58 parts of water.

[0065] The production process of the above-mentioned flame-retardant glass magnesium board comprises the following steps:

[0066] (1) Add light-burned magnesia, anhydrous magnesium sulfate, and forsterite powder into a blender and mix evenly, and then grind into powder by a mill to obtain a mixture a;

[0067] (2) Mix magnesium chloride hexahydrate with water, stir at 30-40°C for 5-10 minutes, add mixed material a, heat up to 50-60°C, then add decabromodiphenyl eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com