Seashore building cement resisting strong wind and big waves

A construction cement and coastal technology, applied in the field of cement, can solve the problems that the concrete structure cannot reach the service life, the structure is difficult to reach the designed service life, and the durability of the concrete structure is affected, so as to achieve excellent durability, improve strength and compactness, Excellent environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

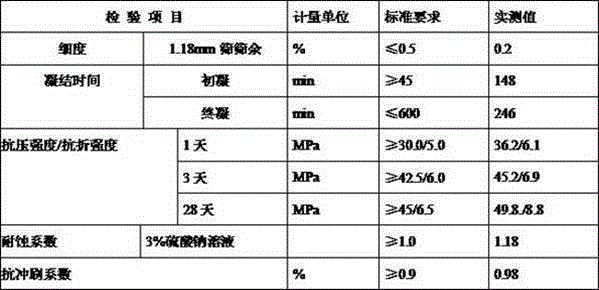

Embodiment 1

[0037] A coastal building cement, comprising the following raw materials in parts by weight: 60 parts of slag; 10 parts of sulphoaluminate cement clinker; 5 parts of silica fume; 0.03 parts of composite activator; 4 parts of early strength agent; 0.3 part of water reducer ; 0.005 parts of air-entraining agent; 0.4 parts of retarder.

[0038] The sulphoaluminate cement clinker is the sulphoaluminate cement clinker produced by replacing aluminum ore with low-grade bauxite or aluminum slag at a ratio of 1:1, with a particle size of 3-30 μm; the weight percentage of its chemical composition For: Al 2 o 3 : 20%-40%, SiO 2 : 2%-10%, Fe 2 o 3 : 5%-15%, SO 3 : 5%-15%, C 4 A 3 S: 40%-65%, C 2 S: 10%-30%, C 4 AF: 20%-35%; the rest is CaO or CaCO 3 .

[0039] The slag is a powder obtained by grinding blast furnace slag, with a fineness of 400m 2 / kg~500m 2 / kg, the weight percentage of its chemical composition is: SiO 2: 30%-40%, Al 2 o 3 : 12%-18%, MgO: 8%-12%, Fe 2 o ...

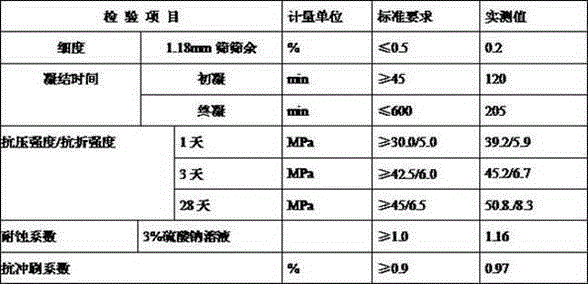

Embodiment 2

[0048] A coastal building cement, comprising the following raw materials in parts by weight: 70 parts of slag; 30 parts of sulphoaluminate cement clinker; 10 parts of silica fume, 0.05 parts of composite activator; 3 parts of early strength agent; 0.4 part of water reducer ; 0.007 parts of air-entraining agent; 0.3 parts of retarder.

[0049] The sulphoaluminate cement clinker is the sulphoaluminate cement clinker produced by replacing aluminum ore with low-grade bauxite or aluminum slag at a ratio of 1:1, with a particle size of 3-30 μm; the weight percentage of its chemical composition For: Al 2 o 3 : 20%-40%, SiO 2 : 2%-10%, Fe 2 o 3 : 5%-15%, SO 3 : 5%-15%, C 4 A 3 S: 40%-65%, C 2 S: 10%-30%, C 4 AF: 20%-35%; the rest is CaO or CaCO 3 .

[0050] The slag is a powder obtained by grinding blast furnace slag, with a fineness of 400m 2 / kg~500m 2 / kg, the weight percentage of its chemical composition is: SiO 2: 30%-40%, Al 2 o 3 : 12%-18%, MgO: 8%-12%, Fe 2 o ...

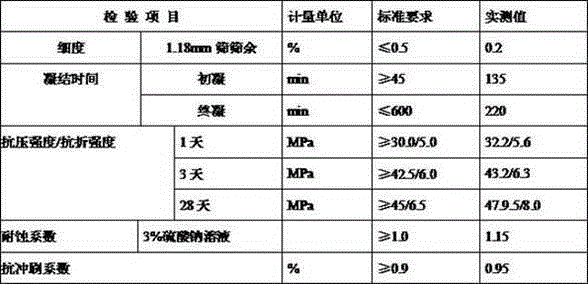

Embodiment 3

[0059] A coastal building cement, comprising the following raw materials in parts by weight: 80 parts of slag; 20 parts of sulphoaluminate cement clinker; 5 parts of silica fume; 0.04 parts of composite activator; 3 parts of early strength agent; 0.5 part of water reducer ; 0.006 parts of air-entraining agent; 0.5 parts of retarder.

[0060] The sulphoaluminate cement clinker is the sulphoaluminate cement clinker produced by replacing aluminum ore with low-grade bauxite or aluminum slag at a ratio of 1:1, with a particle size of 3-30 μm; the weight percentage of its chemical composition For: Al 2 o 3 : 20%-40%, SiO 2 : 2%-10%, Fe 2 o 3 : 5%-15%, SO 3 : 5%-15%, C 4 A 3 S: 40%-65%, C 2 S: 10%-30%, C 4 AF: 20%-35%; the rest is CaO or CaCO 3 .

[0061] The slag is a powder obtained by grinding blast furnace slag, with a fineness of 400m 2 / kg~500m 2 / kg, the weight percentage of its chemical composition is: SiO 2: 30%-40%, Al 2 o 3 : 12%-18%, MgO: 8%-12%, Fe 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com