Grouting material containing circulating fluidized bed fuel coal solid sulfur ash

A coal-fired sulfur-fixing ash and circulating fluidized bed technology, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems that are difficult to meet different requirements of various strata types, secondary pollution of the environment, Easy to pollute the environment and other problems, to achieve the effect of easy control of coagulation time, solve environmental problems, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A sulfur-fixing ash grouting material, the composition and mass percentage of which are: 18% sulfur-fixing ash, 27% cement, 45% sand, 0.4% water reducing agent, and 9.6% water.

[0026] Preparation method: take each component according to the stated ratio, crush, mix and stir evenly, and then obtain the product—sulfur-fixing ash grouting material. The product meets the requirements of GB / T 50448-2008.

Embodiment 2

[0028] A sulfur-fixing ash grouting material, its composition and mass percentage are: sulfur-fixing ash content 18%, cement 27, sand 45, water reducing agent 0.5%, defoamer 0.5%, water 9%.

[0029] The preparation method is the same as in Example 1, and the product is a sulfur-fixed ash grouting material, with a vertical expansion of 3.5%>1h>0.1% and a strength>60MPa at 28d. The product meets the requirements of GB / T 50448-2008.

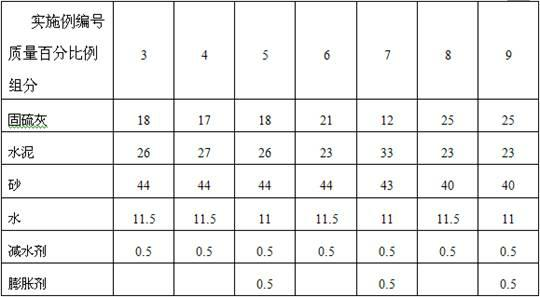

Embodiment 3—9

[0031] A sulfur-fixed ash grouting material, its composition and mass percentage examples are shown in the following table:

[0032]

[0033] The preparation method of embodiment 3-9 is with embodiment 1 or 2, omission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com