Concrete product containing phosphogypsum fly ash cement and preparation method thereof

A technology of concrete products and fly ash cement, which is applied in manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of high cement doping and low utilization rate of phosphogypsum, and achieve high social benefits and shorten Coagulation time, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

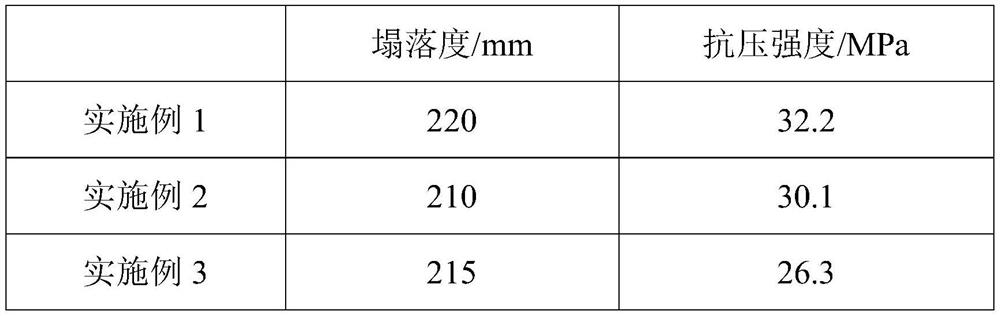

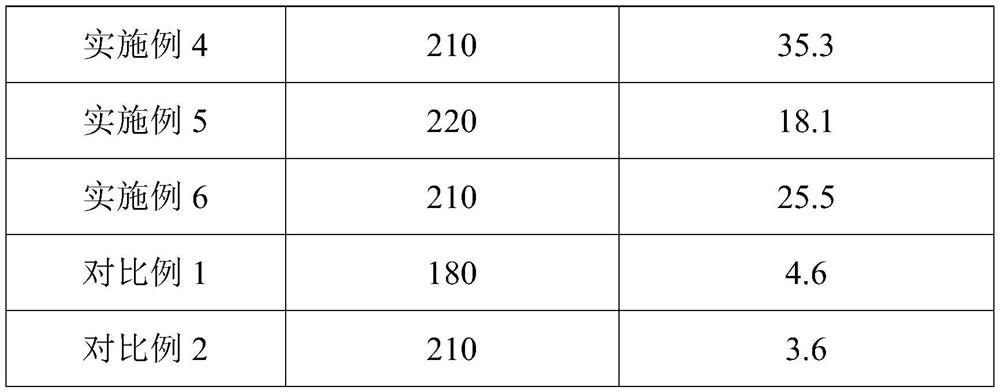

Examples

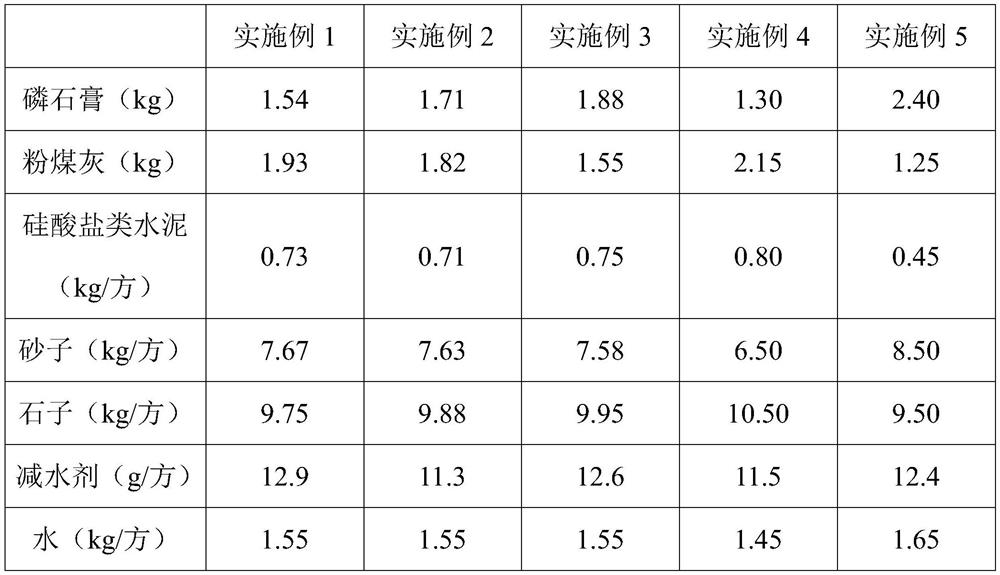

Embodiment 1

[0050] The present embodiment provides a preparation method of concrete products containing phosphorous gypsum fly ash cement, the preparation method comprising the following steps:

[0051] (1) Wetly grind phosphogypsum and some PO42.5 cement with water until the specific surface area is 500m 2 / kg, the mass ratio of the part PO42.5 cement to the phosphogypsum is 0.015, and the mass ratio of the phosphogypsum to the part PO42.5 cement total mass and water is 6:4; the obtained solid content is 62% Phosphogypsum slurry, obtained after filtration and concentration is phosphogypsum mud with a solid content of 82%;

[0052] (2) The phosphogypsum mud obtained in step (1) is mixed with fly ash, remaining PO42.5 cement, sand, gravel, BASF polycarboxylate water reducer and water, and then pressed or poured into concrete products. After molding, let it stand for 1 day, raise the temperature to 65°C and steam for 1 day, take out the product, soak it in water for 1 day, and seal it with...

Embodiment 2

[0054] The present embodiment provides a preparation method of concrete products containing phosphorous gypsum fly ash cement, the preparation method comprising the following steps:

[0055] (1) Grinding of phosphogypsum: Wetly grind phosphogypsum and some slag portland cement with water until the specific surface area is 465m 2 / kg, the mass ratio of said part of slag Portland cement to said phosphogypsum is 0.01, and the mass ratio of said phosphogypsum and part of slag Portland cement to the total mass of water is 5.5:4; the solid content obtained is 59.7 % of the phosphogypsum slurry, after filtration and concentration, the phosphogypsum mud with a solid content of 79.5% is obtained;

[0056] (2) The phosphogypsum mud obtained in step (1) and fly ash, remaining slag Portland cement, stones, sand, (II) Mix polycarboxylate high-efficiency water reducer and water and stir evenly, press or pour into concrete products, after the concrete products are formed, let them stand fo...

Embodiment 3

[0058] The present embodiment provides a preparation method of concrete products containing phosphorous gypsum fly ash cement, the preparation method comprising the following steps:

[0059] (1) Wet-grind phosphogypsum and some pozzolanic portland cement with water until the specific surface area is 455m 2 / kg, the mass ratio of the part of the pozzolanic portland cement to the phosphogypsum is 0.02, and the mass ratio of the total mass of the phosphogypsum to the part of the pozzolanic portland cement to water is 6.5:4; the solid content is obtained phosphogypsum slurry with a solid content of 81.5% after filtration and concentration;

[0060] (2) The phosphogypsum mud obtained in step (1) is mixed with fly ash, remaining pozzolanic Portland cement, stones, sand, combined polycarboxylate water reducer and water, and then pressed or poured into concrete products. After the product is formed, let it stand for 1 day, heat up to 65°C and steam for 1 day, then take out the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com