Dustproof and explosion-proof pelleting and drying equipment for oily sludge

A sludge granulation and granulation technology, which is applied in the direction of granulation, dewatering/drying/concentrating sludge treatment in rotating tanks, etc., can solve problems such as easy explosion, and achieve the reduction of dust generation, safe and stable operation, cost and low cost. The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

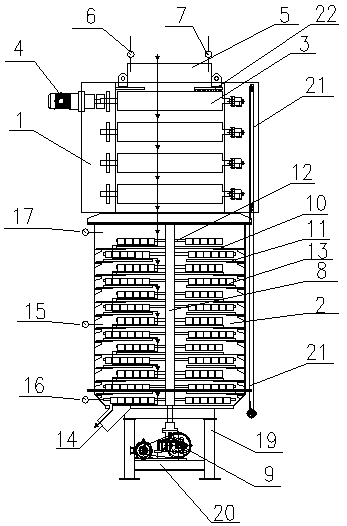

[0023] Such as figure 1 As shown, a dust-proof and explosion-proof oily sludge granulation and drying equipment includes a granulation cabin 1 and a drying cabin 2, the granulation cabin 1 is installed above the drying cabin 2 and the granulation cabin 1 and the drying cabin 2 Connected from top to bottom.

[0024] A number of rollers 3 are horizontally installed in the granulation cabin 1, a motor A4 for driving the rotation of the rollers 3 is installed outside the granulation cabin 1, and a feed inlet 5 is opened above the granulation cabin 1, and a temperature Table A6 and pressure gauge A7, CO 2 Emergency sprinkler 22.

[0025] A rotating shaft 8 is vertically installed inside the drying chamber 2, and the bottom end of the rotating shaft 8 is connected with a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com