Retractable pin mixing sample forming device

一种设备、样品的技术,应用在混合物料的设备领域,能够解决不适合高物料通过量研究技术等问题,达到高收率、收率高、制备周期短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

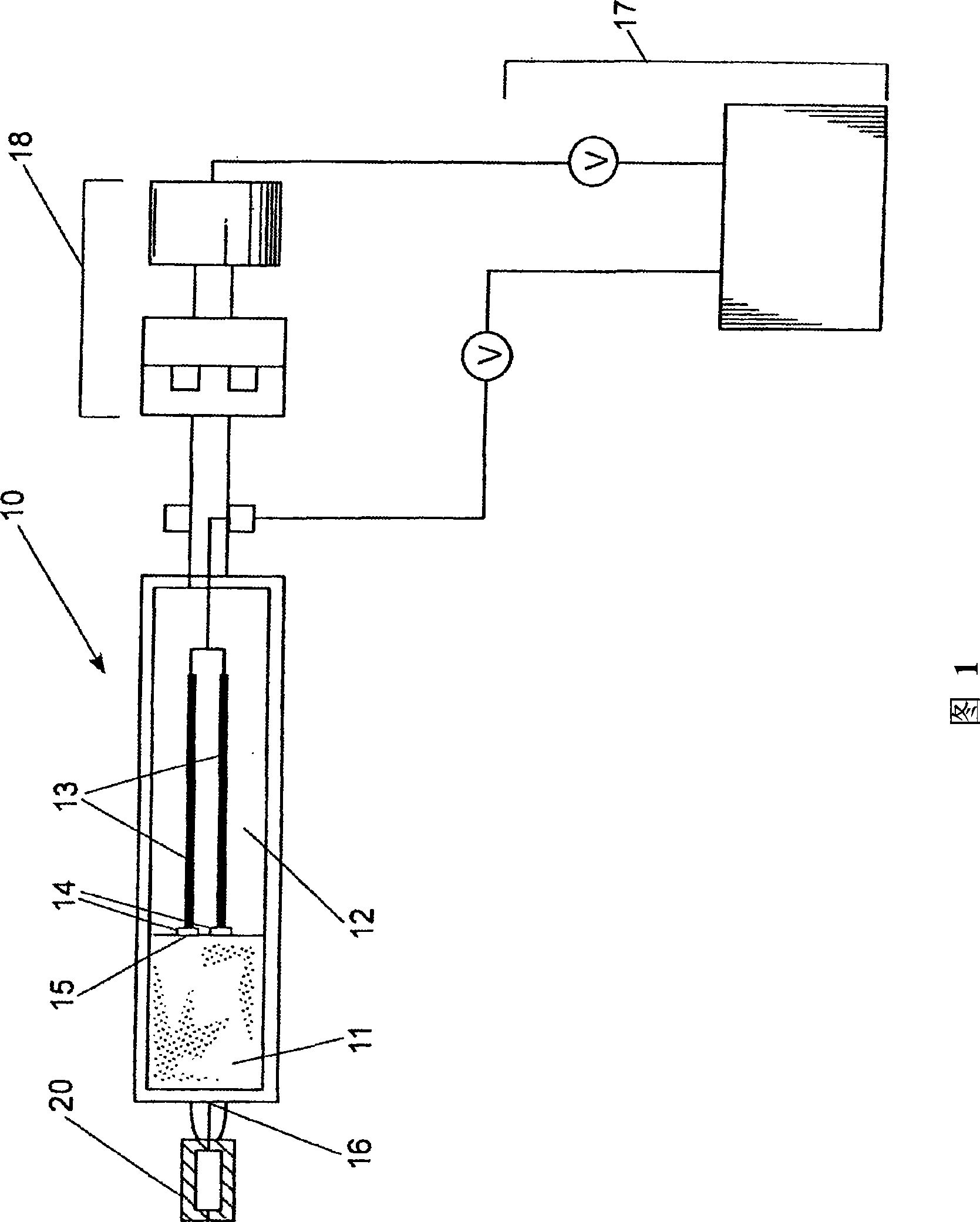

[0058] Using the equipment described above, blends of polystyrene and poly(methyl methacrylate) were prepared using a simple square wave periodic motion. A mixing cycle consists of a set number of rotations of one pin at a constant speed, followed by the same number of rotations of a second pin. For this hybrid procedure, the motion of the two pins is out of phase, but in this case in an on / off fashion rather than sinusoidally. The total mixing program consists of a number of cycles (ie an on / off-off / on sequence) where it is possible to vary the constant pin rotation speed and revolutions per cycle.

[0059] In the device, make STYRON TM 685 Polystyrene (PS) (from The Dow Chemical Company) mixed with 5% w / w poly(methyl methacrylate) (PMMA) from Aldrich (37003-7, nominal molecular weight = 100,000 g / gmol) times. The conditions chosen for mixing were 6 pin revolutions / cycle and 15 revolutions / minute. The compound was extruded through a circular die and samples were taken at...

Embodiment 2

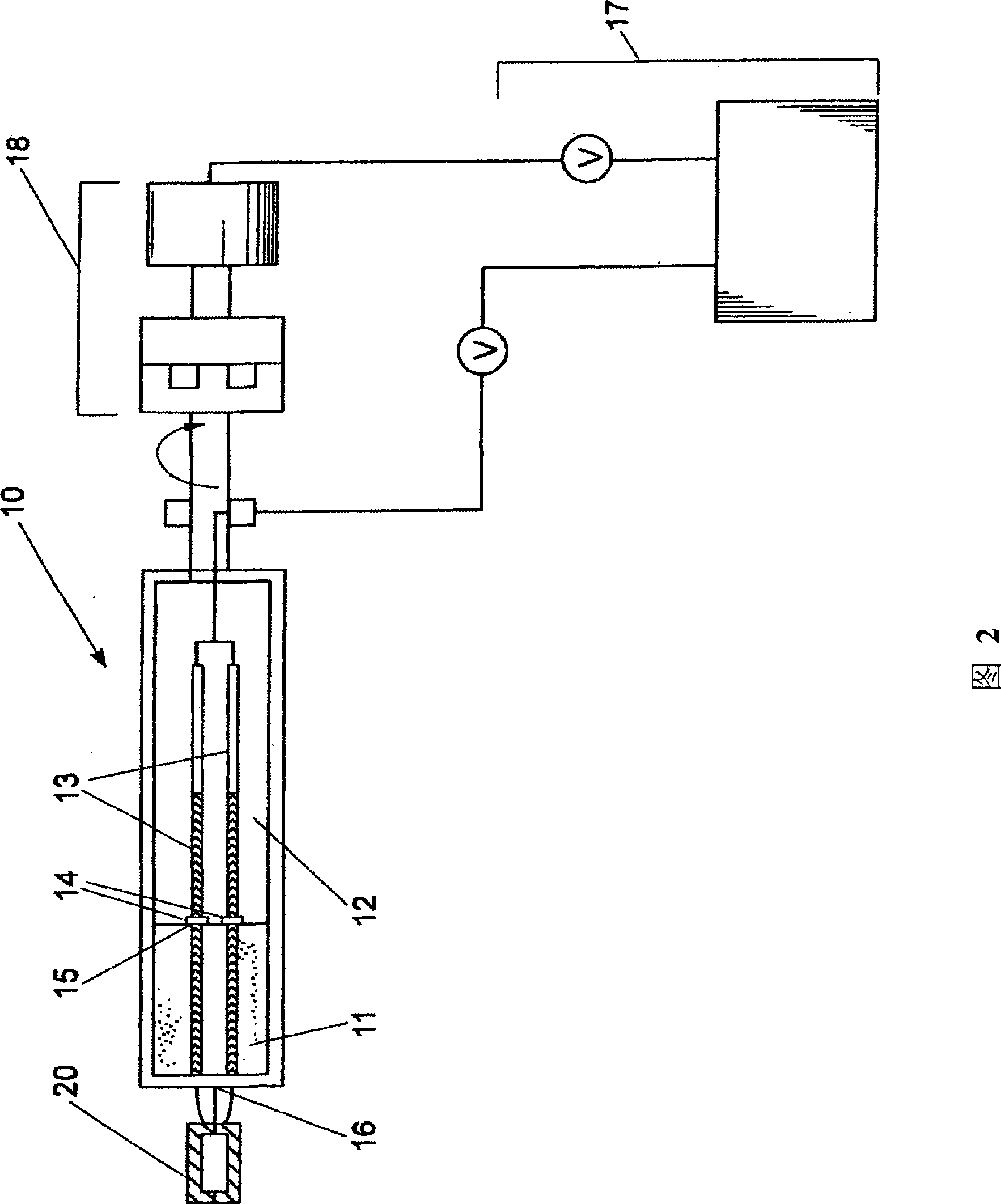

[0061] The mixing capacity of the 2-pin prototype mixer described in Example 1 can be enhanced by using multiple pins. This enhanced capability is demonstrated by the CFD (Computational Fluid Dynamics) model described herein. The modeling conditions used are steady state, laminar flow region, viscosity of 8000 Pa·s, and density of 1064 kg / m3.

[0062] According to these models, 4-pin out-of-order mode operation (square wave) is twice as effective on mixing as the 2-pin out-of-order case used for comparison. Additionally, operating in steady state mixing with a four-pin hybrid is faster than operating in a square wave, random mode on the same equipment at the same rotational speed. Increasing the rotational speed at steady state further reduces the mixing time required.

Embodiment 3

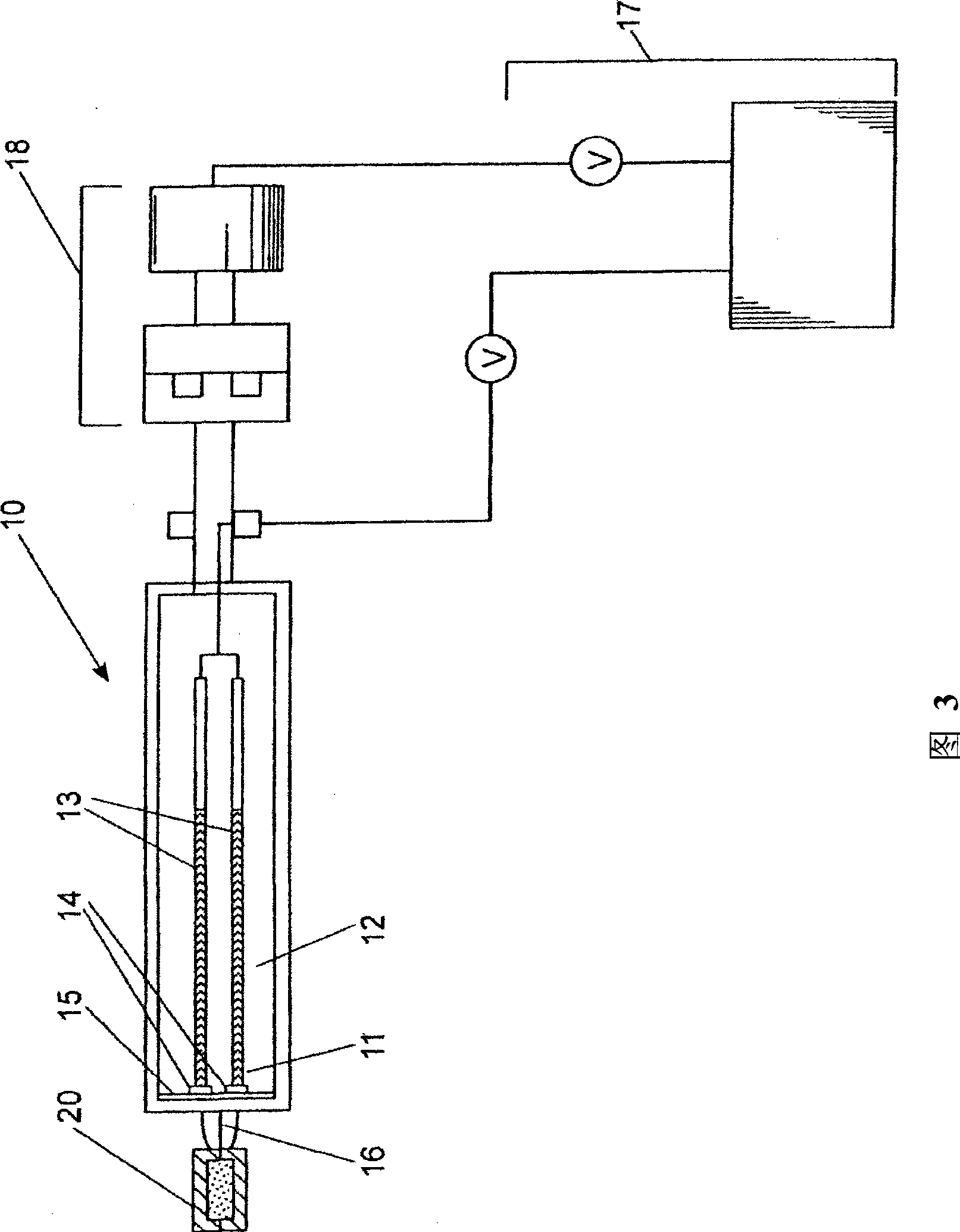

[0064]A series of blends were prepared using the 2-pin mixing apparatus described in Example 1 and their tensile properties were then determined. The 2-pin mixing equipment is equipped with two-part split aluminum moulds. The mold cavity, which measures 2.5 inches (63.5 mm) by 2.5 (63.5 mm) by 0.064 inches (1.62 mm), is gated by a cylindrical channel connected to the exit path of the mixer. The mold is secured by bolting the cavity-containing side of the mold to the base of the mixer. The parting surface of the mold can move along the track. It is bolted in place during molding, but is easily removed after partial curing to remove plaque and sprue. Both parts of the mold have machined channels through which fluid can be circulated for temperature control of the mold.

[0065] Blends and molded panels were prepared by the methods described below. The temperature of the chamber and base was set to 230°C. The two halves of the flat mold were bolted together and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com