Degradable biomedical forging-state magnesium alloy and preparation method thereof

A biomedical and magnesium alloy technology, which is applied in the field of degradable biomedical materials, can solve the problems of improving strength and performance, and achieve the effects of reducing the thickness of the diffusion layer, improving flow and diffusion, and reducing component segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

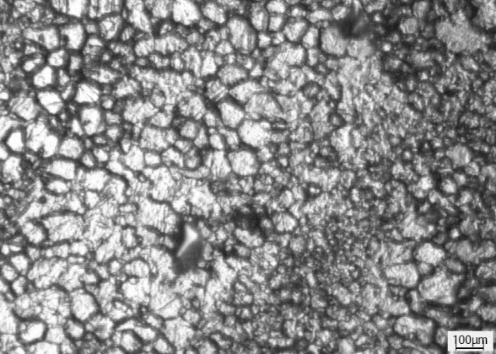

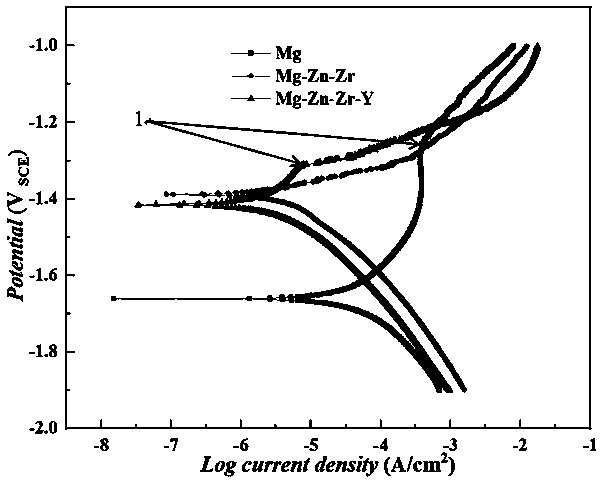

Image

Examples

Embodiment 1

[0033] A forged magnesium alloy for biodegradable biomedical use, the mass percent composition is: 4.1% Zn, 0.23% Zr, 0.93% Y, the mass ratio of Zn / Y is 4.39, and the balance is Mg.

[0034] The preparation method of the above-mentioned degradable biomedical wrought state magnesium alloy comprises the following steps:

[0035] (1) Material preparation step: put Zn particles and master alloy into the crucible according to the ratio, and the master alloy is ZK60 and Mg-30%Y;

[0036] (2) Melting step: Introduce argon gas into the melting furnace to evacuate the air, heat the melting furnace, and preheat the crucible to 660°C to melt the magnesium alloy ingredients;

[0037] (3) Refining step: adding a refining agent to the melted magnesium ingot for refining;

[0038] (4) Stirring step: stirring the refined magnesium ingots to completely melt the magnesium alloy ingredients;

[0039] (5) Production steps: pouring, cooling, forging slabs, and rolling to obtain biomedical magnes...

Embodiment 2

[0044] A forged magnesium alloy for biodegradable biomedical use, the mass percent composition is: 4.45% Zn, 0.38% Zr, 0.75% Y, the Zn / Y mass ratio is 5.93, and the balance is Mg.

[0045] The preparation method of the above-mentioned degradable biomedical wrought state magnesium alloy comprises the following steps:

[0046] (1) Material preparation step: put Zn particles and master alloy into the crucible according to the ratio, and the master alloy is ZK60 and Mg-30%Y;

[0047] (2) Melting step: Introduce argon gas into the melting furnace to evacuate the air, heat the melting furnace, and preheat the crucible to 700°C to melt the magnesium alloy ingredients;

[0048] (3) Refining step: adding a refining agent to the melted magnesium ingot for refining;

[0049] (4) Stirring step: stirring the refined magnesium ingots to completely melt the magnesium alloy ingredients;

[0050] (5) Production steps: pouring, cooling, forging slabs, and rolling to obtain biomedical magnesiu...

Embodiment 3

[0055] A forged magnesium alloy for biodegradable biomedical use, the mass percent composition is: 5.6% Zn, 0.1% Zr, 1.26% Y, the Zn / Y mass ratio is 4.44, and the balance is Mg.

[0056] The preparation method of the above-mentioned degradable biomedical wrought state magnesium alloy comprises the following steps:

[0057] (1) Material preparation step: put Zn particles and master alloy into the crucible according to the ratio, and the master alloy is ZK60 and Mg-30%Y;

[0058] (2) Melting step: Introduce argon gas into the melting furnace to evacuate the air, heat the melting furnace, and preheat the crucible to 720°C to melt the magnesium alloy ingredients;

[0059] (3) Refining step: adding a refining agent to the melted magnesium ingot for refining;

[0060] (4) Stirring step: stirring the refined magnesium ingots to completely melt the magnesium alloy ingredients;

[0061] (5) Production steps: pouring, cooling, forging slabs, and rolling to obtain biomedical magnesium ...

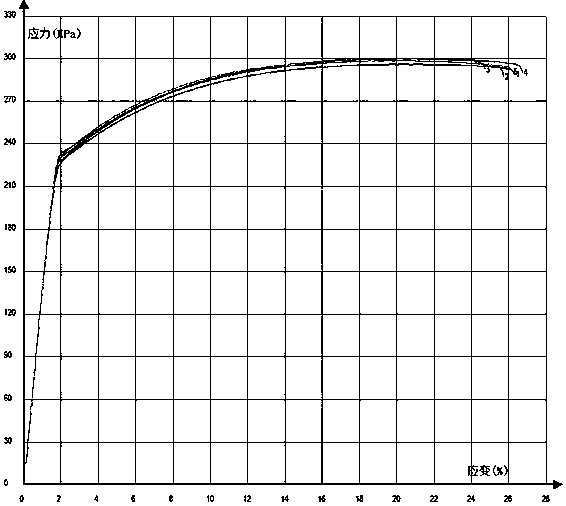

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com