Method and device for encapsulating electronic components with a conditioning gas

A technology of electronic components and packaging devices, which is applied in the field of packaging electronic components, can solve the problems of unusable mold parts, product loss, and the process of adhesion growth cannot be completely predicted and understood, and achieve the effect of preventing cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

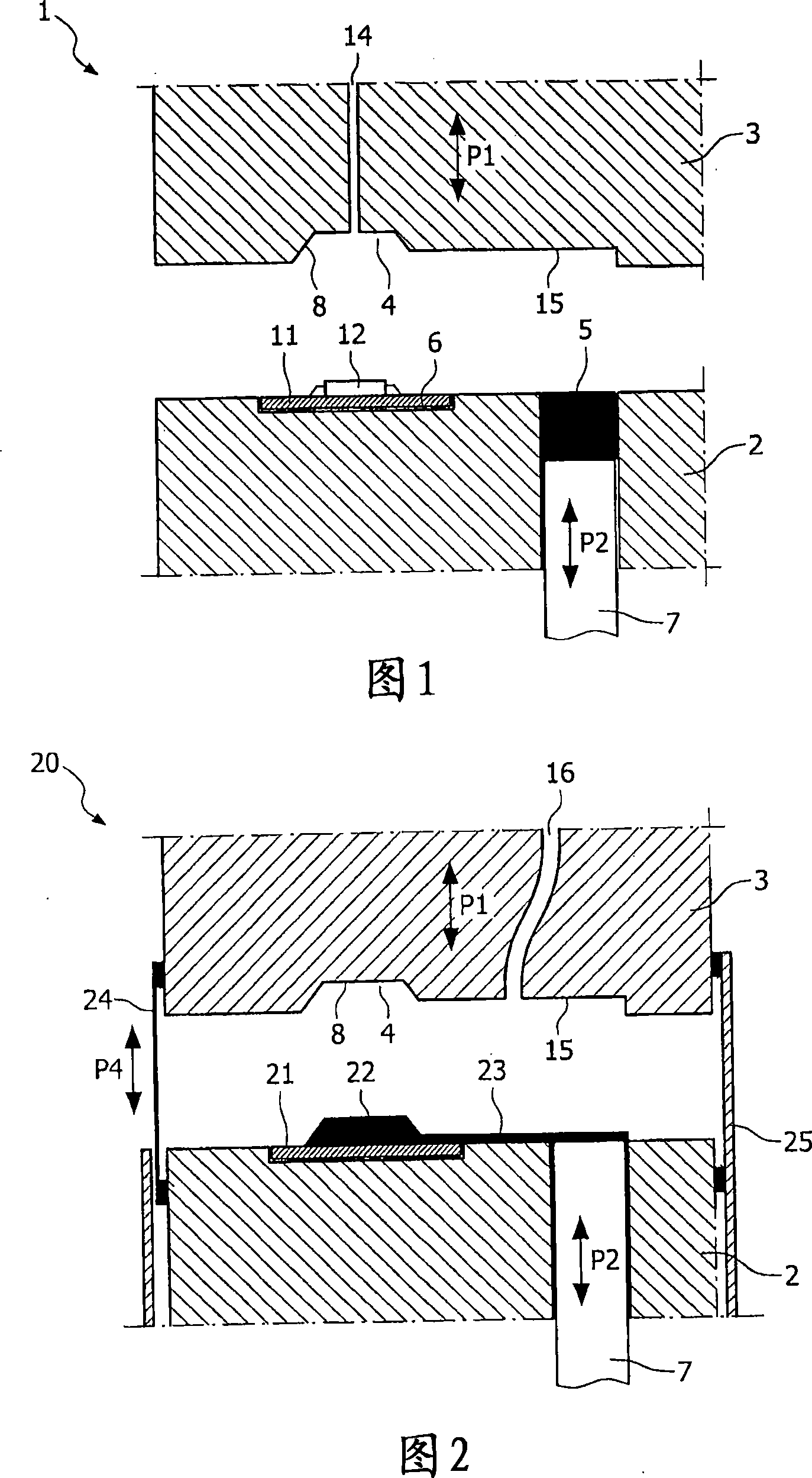

[0021] Figure 1 shows a packaging device 1 having a lower end-mold part 2 which is replaceable with respect to an upper end-mold part 3, as indicated by arrow P1. To form a housing, which is produced from a potting material 5 , the upper mold part 3 has a mold cavity 4 , not shown in this figure, which is clearly visible on the left. In the lower end mold part 2 a recess 6 is provided, on which a carrier with electronic components 12 is placed. The encapsulating material 5 can be applied to the mold cavity 4 via a replaceable plunger 7 as indicated by the arrow P2. Recessed into the upper mold part 3 is an optionally closeable channel 14 connected to the mold cavity 4 . The conditioning gas is fed directly into the mold cavity 4 via the channel 14 and at the same time exerts (at least partially acts on) a force on the encapsulation material 5 in order to release the encapsulation material 5 from the contact side 8 of the mold cavity 4 .

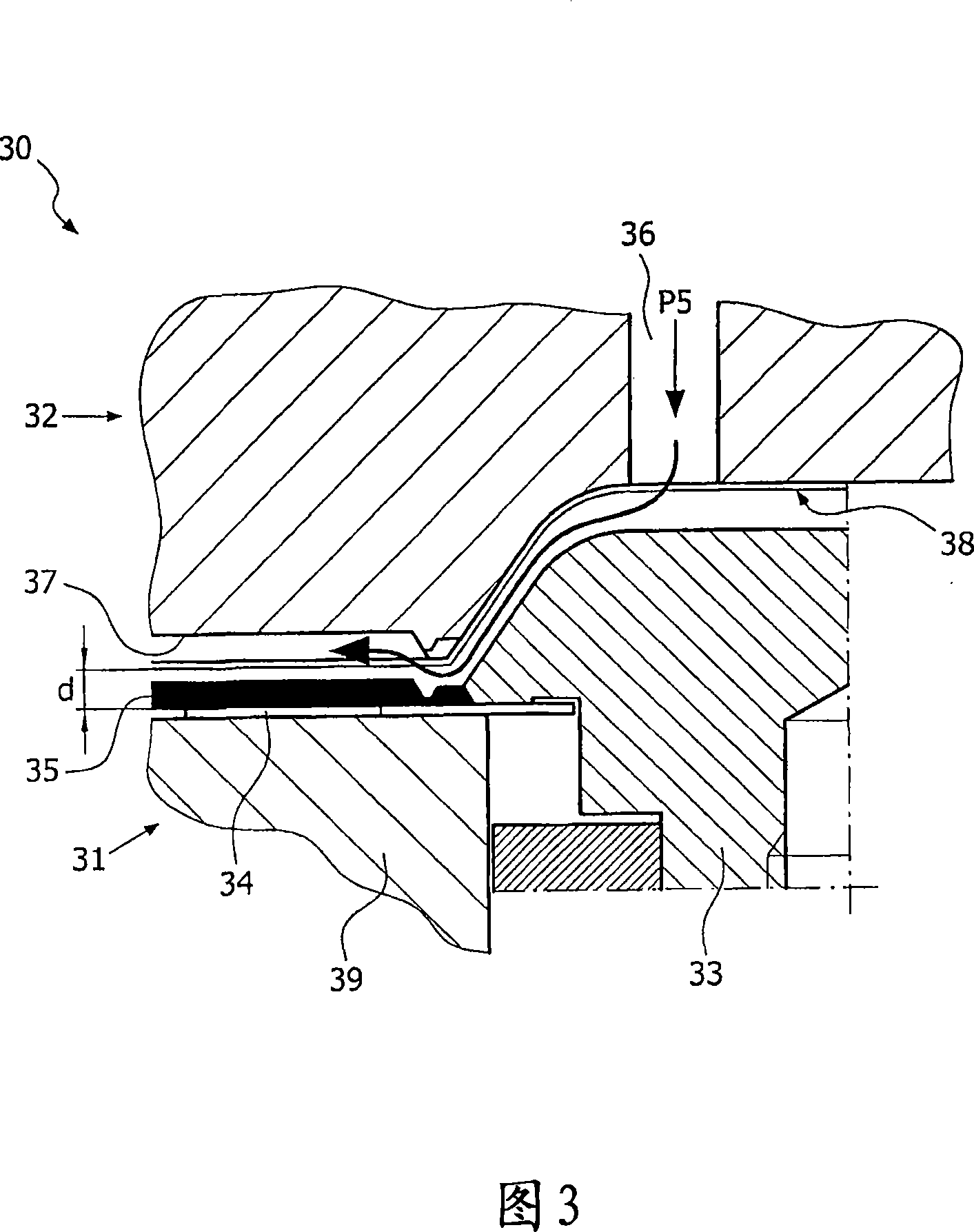

[0022] FIG. 2 shows a packaging devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com