10-DOF floor exercise robot

A floor exercise, robotics technology, applied in manipulators, manufacturing tools, etc., can solve problems such as complexity, difficulty in mechanical analysis and motion control, and increased robot weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

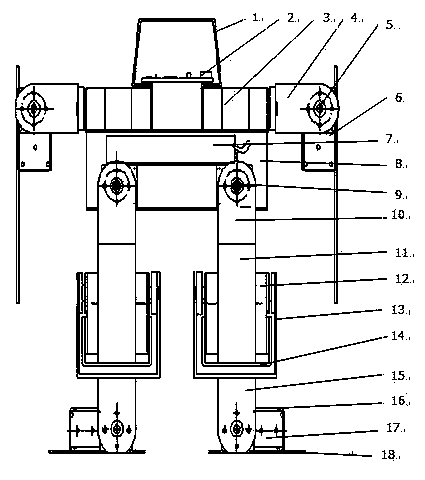

[0011] figure 1 The structural diagram of a ten-degree-of-freedom floor exercise robot of the present invention is given from the perspective of a cross-sectional view. The robot drives ten joints through a motor to make the center of gravity of the robot move left and right, thereby realizing the forward movement of the robot. Rolls, back rolls, rollovers, handstands, handstand splits and push-ups. In addition, the operator can also make the robot complete some other floor exercises according to the needs, so as to make the robot's movements more coherent and improve the appreciation. The two elongated ends bent by the head part 1 are threadedly connected with the shoulder motor 3; the outer end of the torque output shaft of the shoulder motor 3 is connected with the shoulder U-shaped part 4, and the direction of the torque output shaft of the shoulder motor 3 is Perpendicular to the forward direction of the robot; the hand motor 5 is threadedly connected to both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com