Joint unit, finger device and gripper

A joint and unit connection technology, applied in the field of finger devices, grippers and joint units, can solve problems such as small workspaces, and achieve the effect of providing response speed, stable output torque, simple motion and mechanical inverse calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

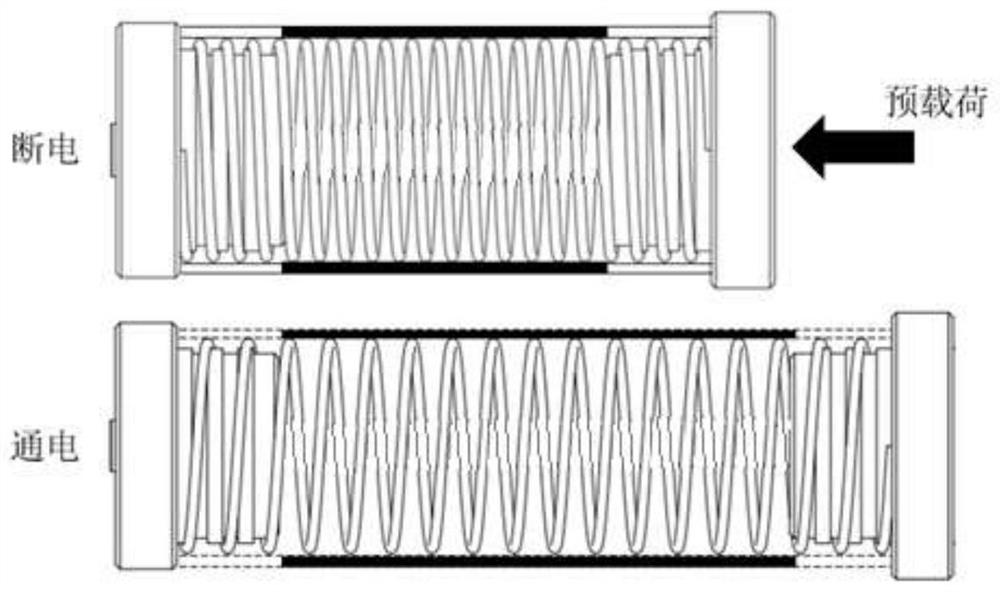

[0060] This embodiment provides a joint unit, which uses the linear drive of the cylindrical EAP driver to realize the degree of freedom of movement of the joint unit, and uses the SMA driver to realize the degree of freedom of rotation of the joint unit, which solves the problem of using EAP drive and SMA drive in the prior art. The technical problem of the small working space of the mechanical fingers.

[0061] like Figure 5 to Figure 7 The joint unit shown contains:

[0062] a cylindrical EAP driver, the cylindrical EAP driver comprising:

[0063] The first spring 2, the first spring 2 includes a first end and a second end;

[0064] guide rod 1, the guide rod 1 and the first spring 2 are coaxially arranged;

[0065] EAP film 8, EAP film 8 is wound several layers on the first spring 2, as Image 6 As shown, a plurality of flexible conductive units 11 are disposed on the EAP film 8, and the flexible conductive unit 11 includes electrode lead wires 1104, the electrode lea...

Embodiment 2

[0093] This embodiment provides a finger-shaped device, which includes two joint units in Embodiment 1. At the connection of the joint units: the first end of the first spring of one joint unit and the second spring of the other joint unit The second end connection.

[0094] The same or different bending deformation directions of the SMA drivers of the two joint units are beneficial to increase the working space of the finger device.

Embodiment 3

[0096] This embodiment provides a gripper, comprising three joint units and palm plates in Embodiment 1, the first end of the first spring of each joint unit is rotatably connected to the palm plate, and the three joint units Evenly distributed with respect to the center of the palm plate.

[0097] When performing a grasping action, the three joint units contact the target object from different directions, and cooperate with each other to complete the grasping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com