Multi-nozzle and multi-channel heater of steam-water two phase flow mixed type

A heater, multi-channel technology, used in direct contact heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as high noise, water hammer, and inability to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

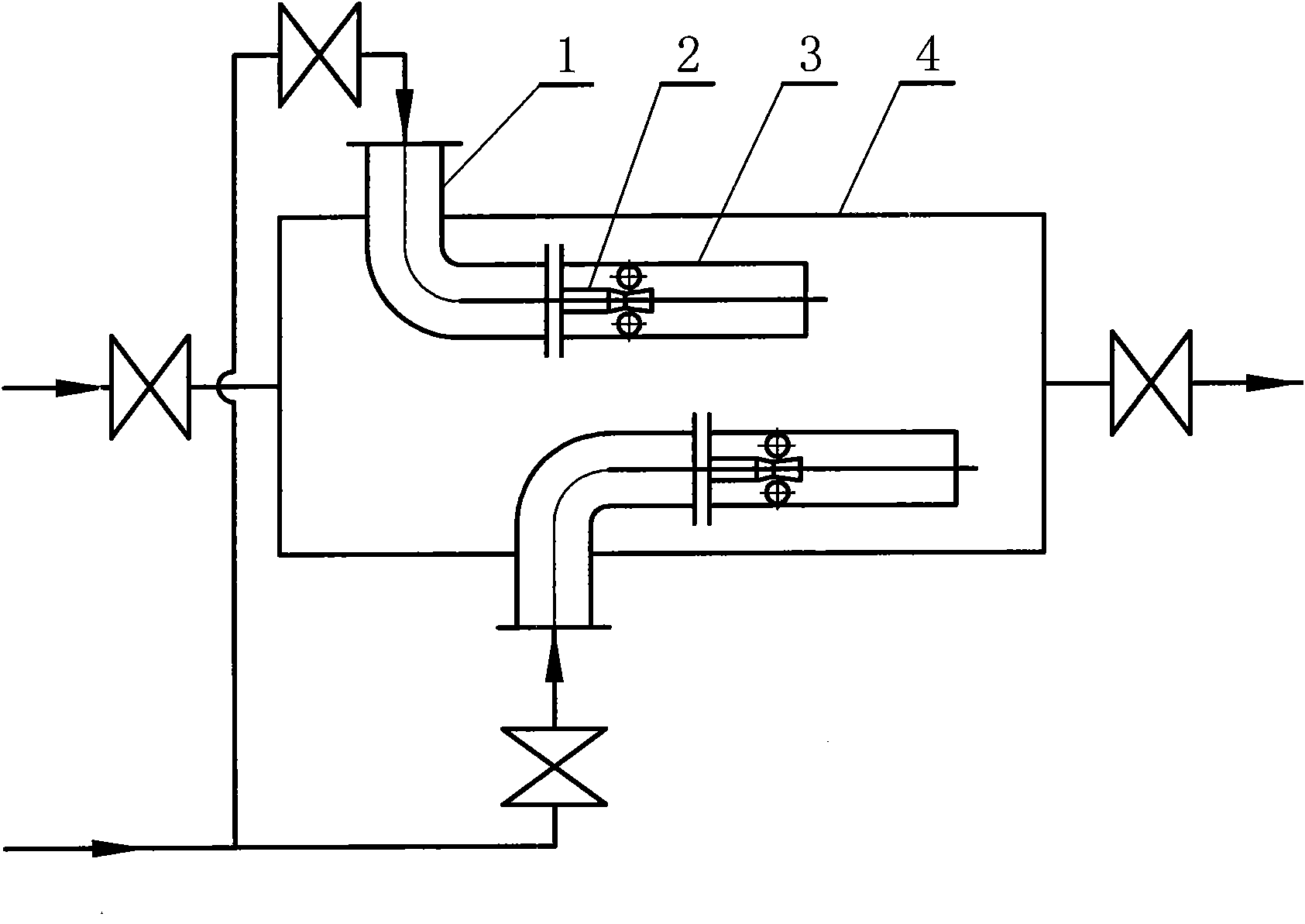

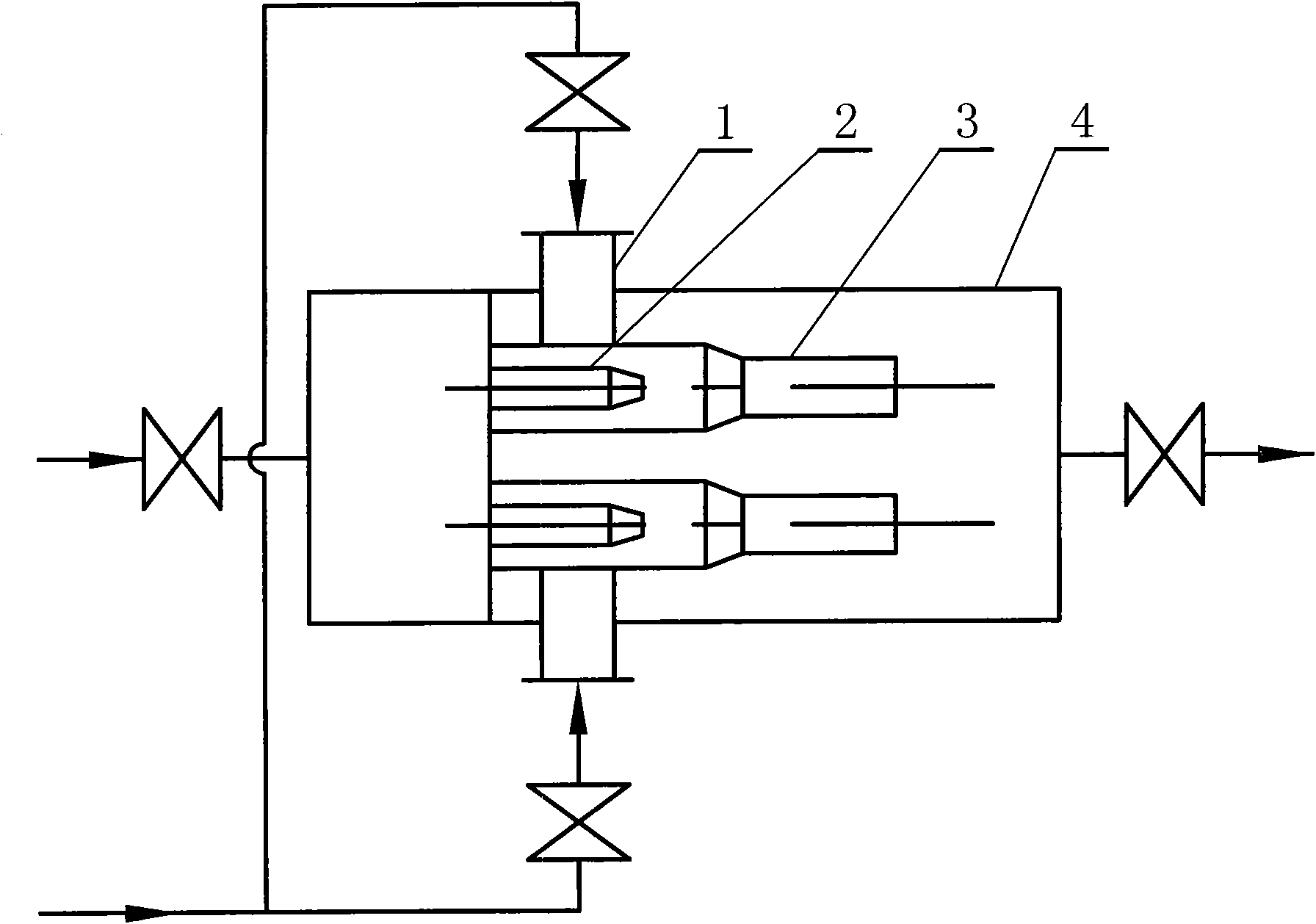

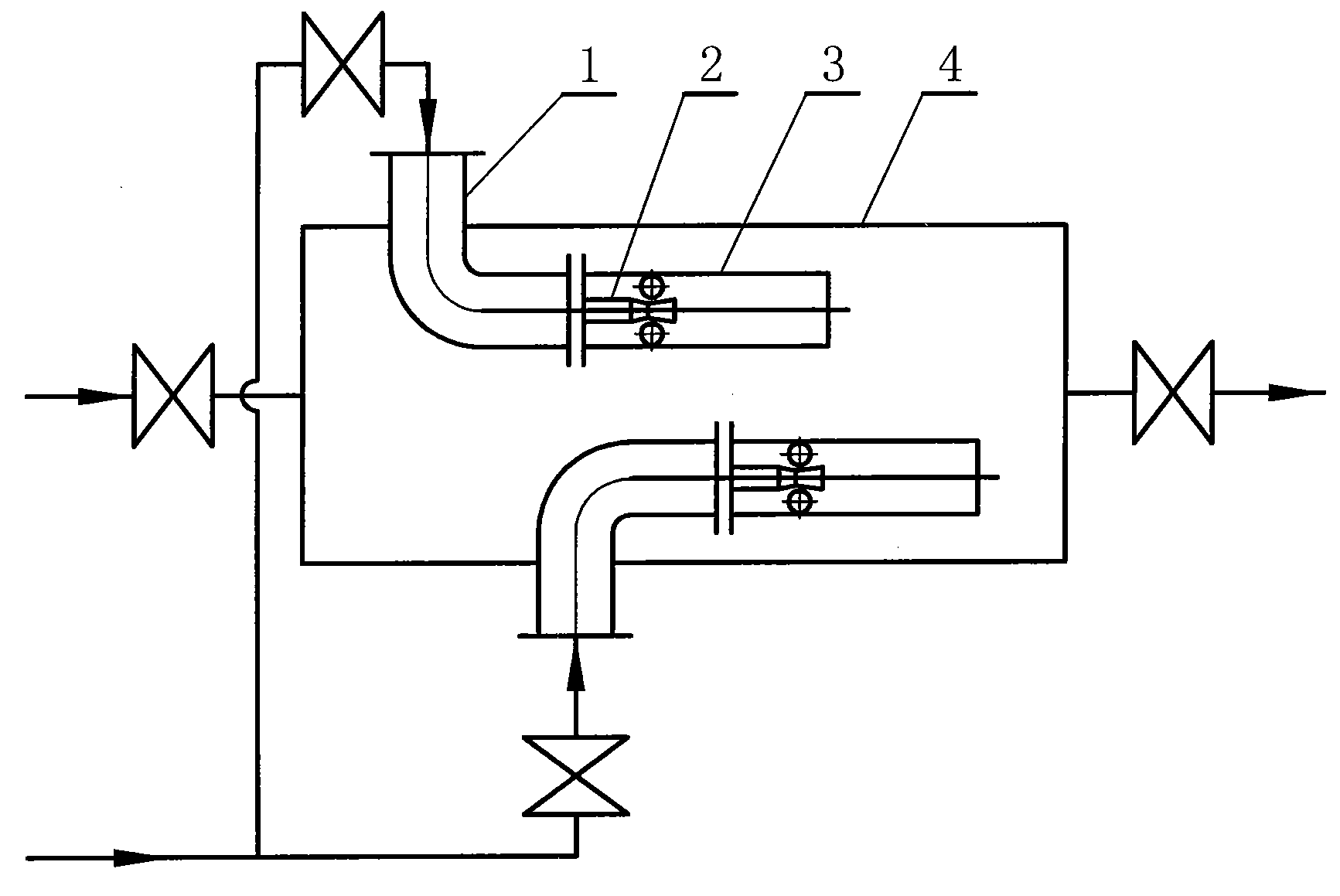

[0017] Such as figure 1 As shown, the multi-nozzle multi-channel steam-water two-phase flow hybrid heater of the present invention is a two-phase heater with steam injection and water, and the steam is injected by the nozzle to inhale water for heating. It consists of a channel and a heater housing 4, there are 2 channels, and each channel is composed of a steam inlet 1, a nozzle 2 and a mixing tube 3. The steam inlet 1 and the mixing pipe 3 are connected into an integral structure through an elbow.

[0018] When the working condition of the two-phase heater with steam injection and water changes, the outlet temperature changes. At this time, the steam flow needs to be adjusted according to the temperature change. The change of the steam flow is realized by the multi-channel steam regulating valve. The multi-channel steam regulating valve is in the adjustment process. Only changing the opening of one steam channel does not affect the working conditions of other channels, so t...

Embodiment 2

[0021] Such as figure 1 As shown, the multi-nozzle multi-channel steam-water two-phase flow hybrid heater of the present invention is a two-phase heater with water jet and steam, and the water is sprayed by the nozzle to inhale the steam for heating. It consists of a channel and a heater housing 4, there are 2 channels, and each channel is composed of a steam inlet 1, a nozzle 2 and a mixing tube 3. The steam inlet 1 is in communication with the mixing tube 3, and the steam inlet 1 and the mixing tube 3 are of separate structures.

[0022] There may also be 5, 7 or 10 channels described in this embodiment.

[0023] For the two-phase flow heater with water jet and steam, in order to keep the outlet hot water pressure and temperature stable, it is necessary to adjust the opening of the water nozzle and the steam regulating valve at the same time. The water nozzle regulating valve and the steam regulating valve are multi-channel regulating valves. Individual channels can be clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com