Contraction type heat exchanger

A technology of heat exchangers and heat exchange tubes, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of affecting heating effect, evaporator congestion, pressure drop sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

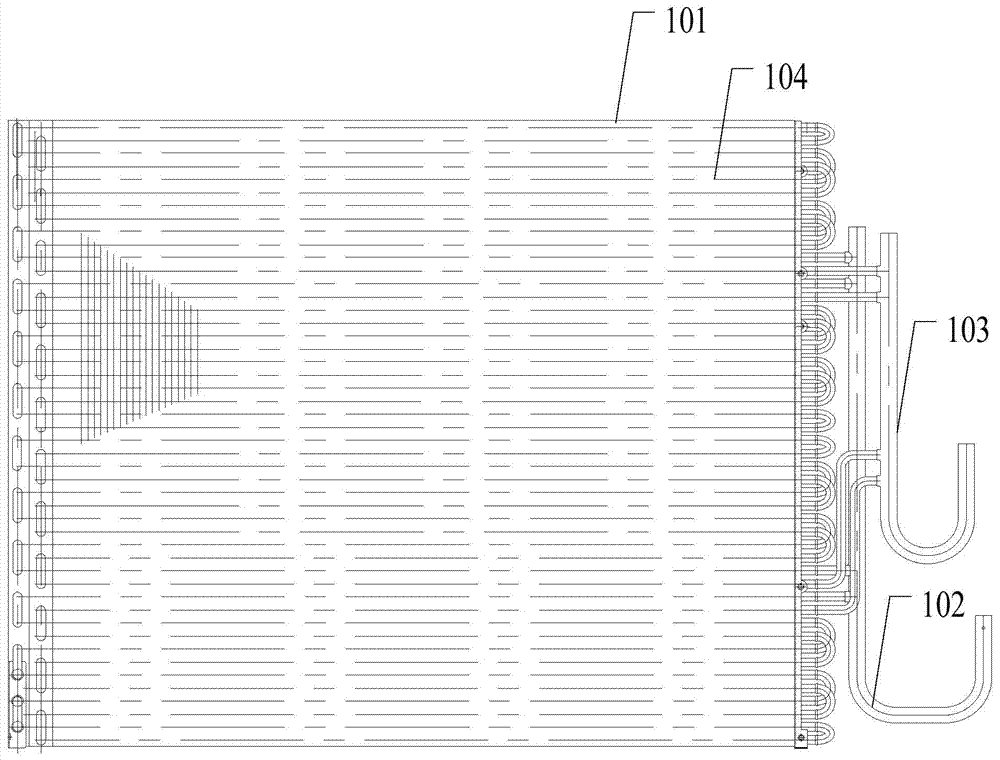

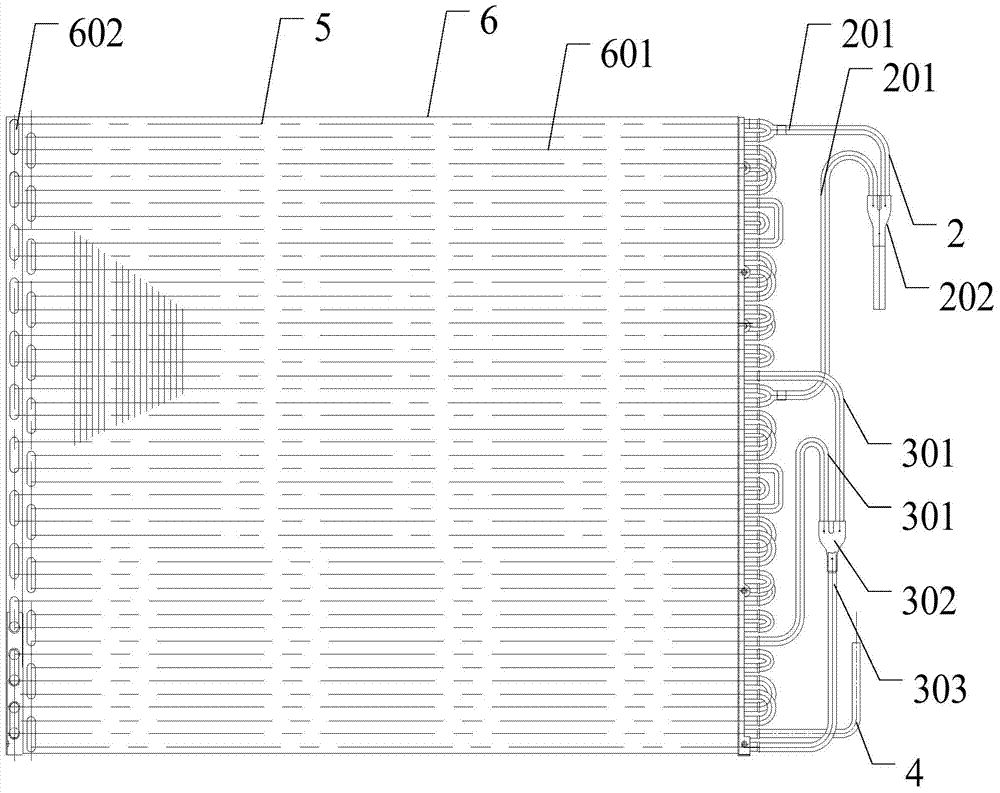

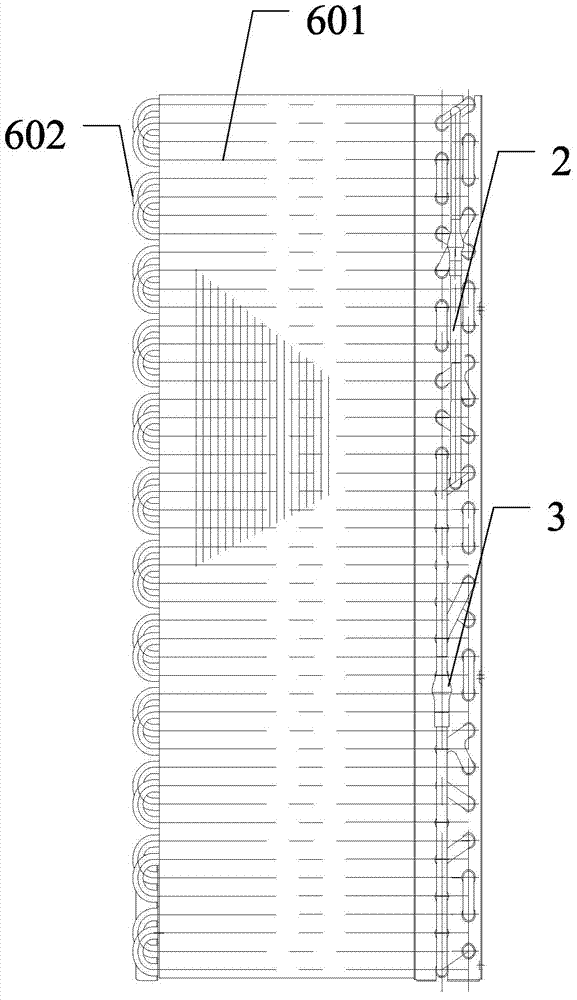

[0033] See figure 2 with image 3 , figure 2 It is a schematic diagram of the structure of a shrinkable heat exchanger of the present invention, image 3 for figure 2 Side view.

[0034] A shrink-type heat exchanger of this embodiment includes a body, the body is provided with a heat exchange tube assembly 6, and the body is provided with an intake pipe assembly 2, a manifold assembly 3, and a main outlet pipe 4;

[0035] The intake pipe assembly 2 includes a plurality of intake pipes 201 and a multi-way pipe 202. One end of each intake pipe 201 is connected to the corresponding heat exchange tube assembly 6 and forms multiple branches. The other end of each intake pipe 201 converges to the multi-way pipe 202;

[0036] The manifold assembly 3 includes an outlet branch pipe (not indicated in the figure) corresponding to each branch, a multi-way pipe 302, and a manifold. The outlet branch pipe includes the manifold that flows to the manifold through the multi-way pipe 302. The firs...

Embodiment 2

[0043] See Figure 2 ~ Figure 5 , figure 2 It is a schematic diagram of the structure of a shrinkable heat exchanger of the present invention, image 3 for figure 2 Side view of Figure 4 It is a vertical cross-sectional view of the connecting pipe of a shrinkable heat exchanger of the present invention, Figure 5 It is a transverse sectional view of a connecting pipe of a shrinkable heat exchanger of the present invention.

[0044] A shrink-type heat exchanger of this embodiment includes a body, the body is provided with a heat exchange tube assembly 6, and the body is provided with an intake pipe assembly 2, a manifold assembly 3, and a main outlet pipe 4;

[0045] The intake pipe assembly 2 includes a plurality of intake pipes 201 and a multi-way pipe 202. One end of each intake pipe 201 is connected to the corresponding heat exchange tube assembly 6 and forms multiple branches, and the other end of each intake pipe 201 converges to the multi-way pipe 202;

[0046] The manifold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com