Heating network heater internally provided with draining well

A heat network heater and water well technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of large space occupied by heat network heaters, poor stress conditions on the end plates of drain wells, and material consumption Large volume and other problems, to achieve the effect of small space occupied by the equipment, eliminate the inducing factors of pipe vibration and pipe burst, and expand the steam circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

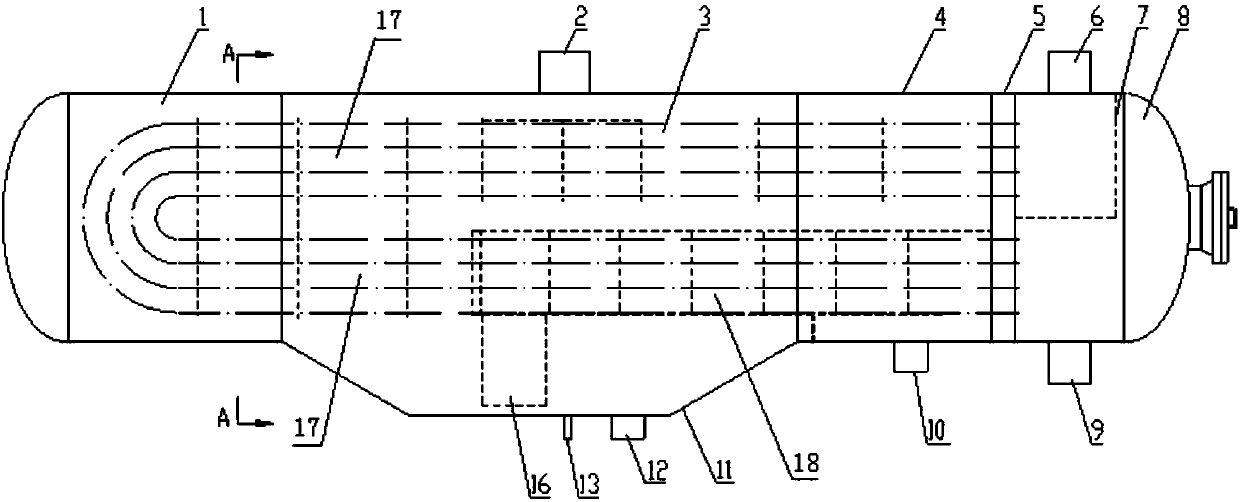

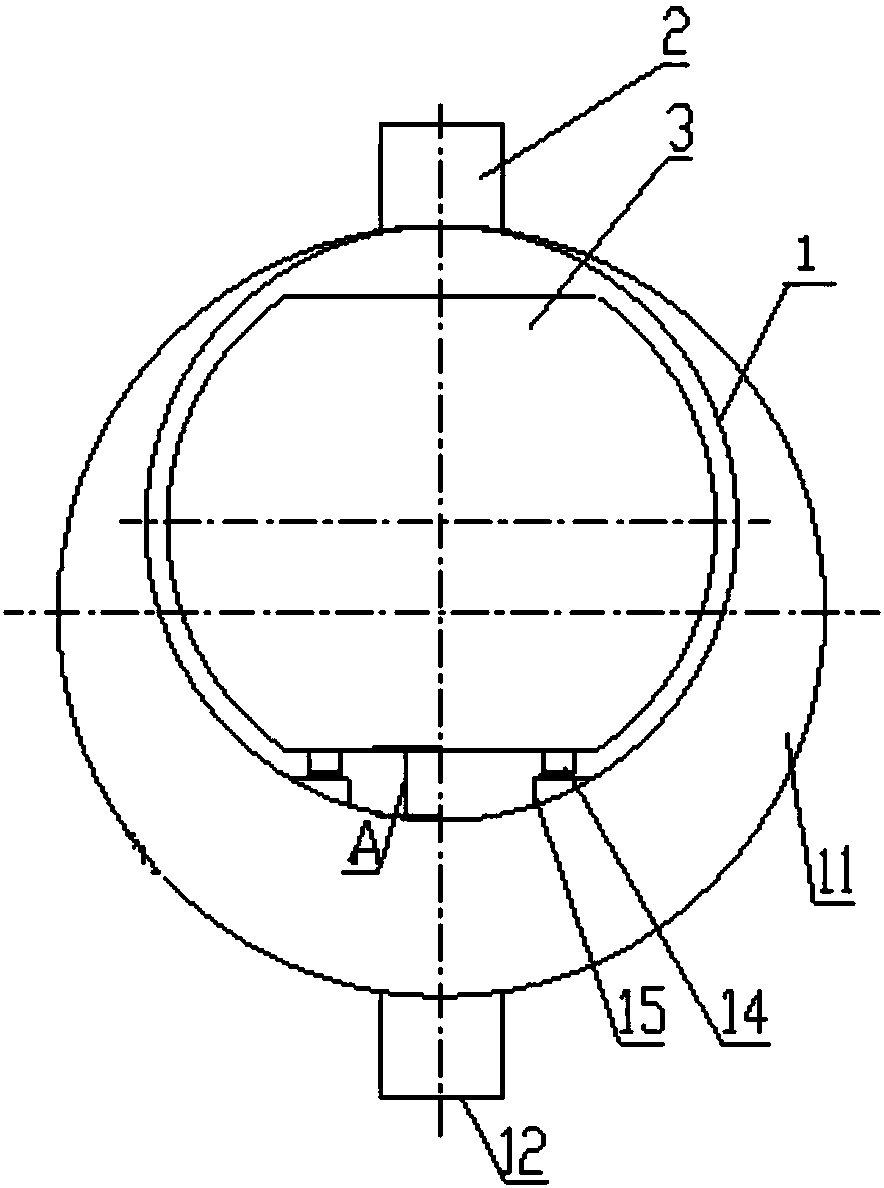

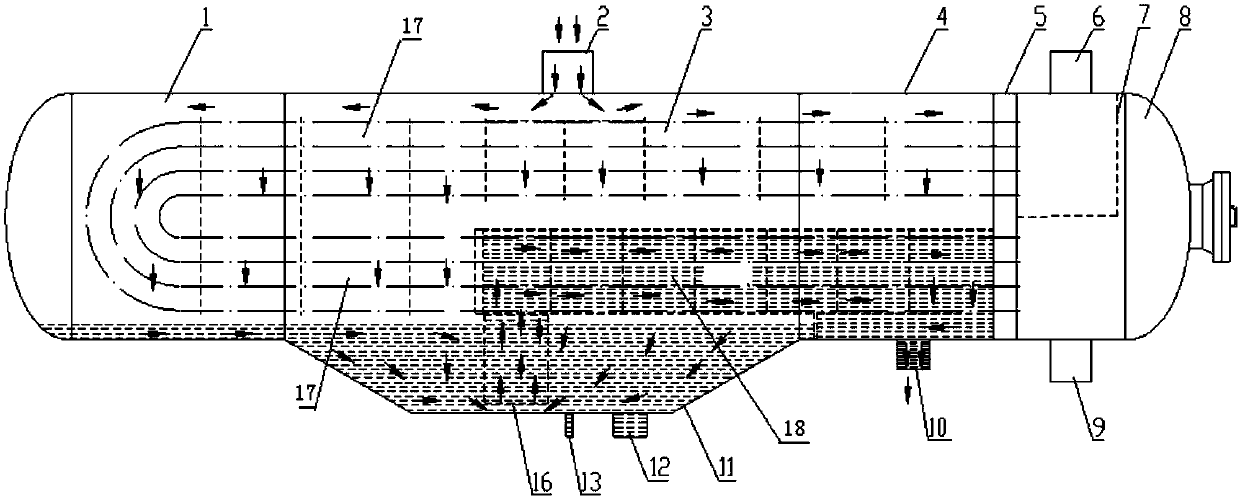

[0020] refer to Figure 1-3 As shown, the cylinder section 4 is welded to the tube sheet 5, the eccentric shell 11 (composed of two eccentric conical shells and a large-diameter cylinder), the cylinder section 4 and the cylinder body 1 form the shell, and the tube sheet 5 is connected to the U-shaped heat exchange tube bundle 3 , The U-shaped heat exchange tube bundle 3 is divided into a saturation section 17 and a cooling section 18 . The eccentric case 11 is eccentric downward relative to the barrel body 1 and the barrel section 4. The eccentric case 11 sinks below the bottom of the barrel body 1 and the barrel section 4 to form a drainage well. Drain well, the bottom of the drain well is provided with an emergency drain port 12 and a water discharge port 13, the upper part of the eccentric shell 11 is provided with a steam inlet 2, the cylinder section 4 is provided with an air release port of the cooling section and a drain outlet 10, and the upper part of the cylinder bod...

Embodiment 2

[0022] This embodiment is basically the same as Embodiment 1, the difference being that the emergency drain opening 12 is set at the bottom of the drain well, and the water outlet is at the lowest point of the emergency drain pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com