Constant flow velocity steam-water heat exchanger

A water heat exchanger, heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, steam/steam condenser, etc., can solve the problems of affecting heat exchange, immersion, obvious flow resistance, etc., to reduce the exchange rate. Heat area, reduce material consumption, improve the effect of heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiment is as follows in conjunction with accompanying drawing description:

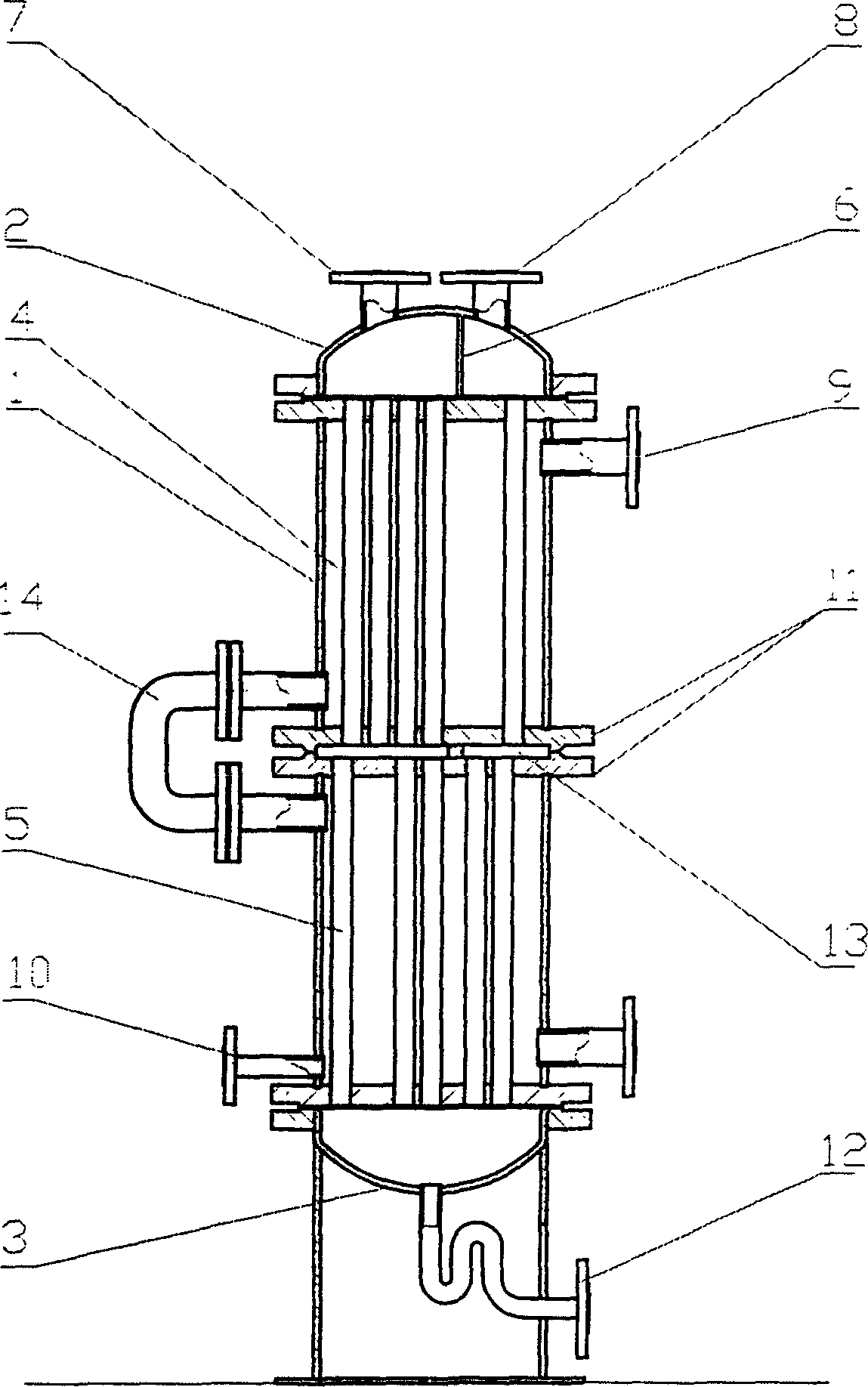

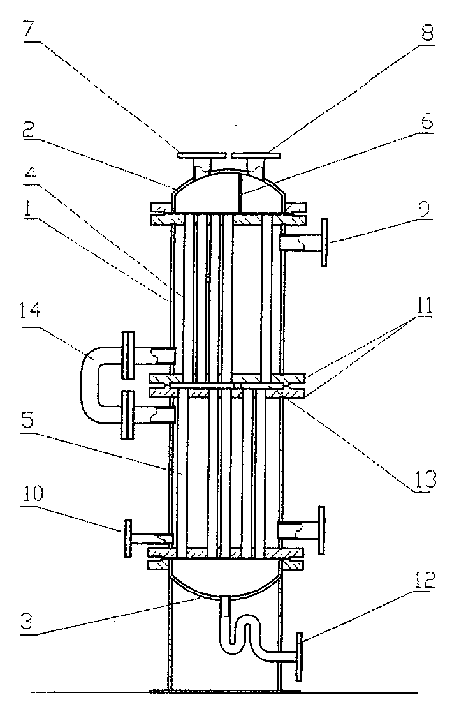

[0008] Equal flow velocity steam-water heat exchanger of the present invention ( figure 1 ) consists of a head 2, a heat exchanger body 1, and a condensate collector 3; there is a steam inlet 7 and a steam outlet 8 on the head; there is a partition 6 inside the head 2 to separate the incoming steam from the discharged steam, The head 2 and the heat exchanger body 1 are connected by flanges; the heat exchanger body 1 is formed by connecting two independent units through flanges; each independent unit is equipped with two sets of heat exchange tube groups 4 with different numbers of tubes, The direction of steam flow in the two groups of tubes is opposite, one group flows from top to bottom, and the other group flows from bottom to top; two independent units are connected by a tube sheet 11, and there is a cavity 13 between the tube sheets to flow downward , the other group flows from bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com