Preparation method of easy-for-turning Be-Cu alloy resistant to high-temperature softening and stress relaxation

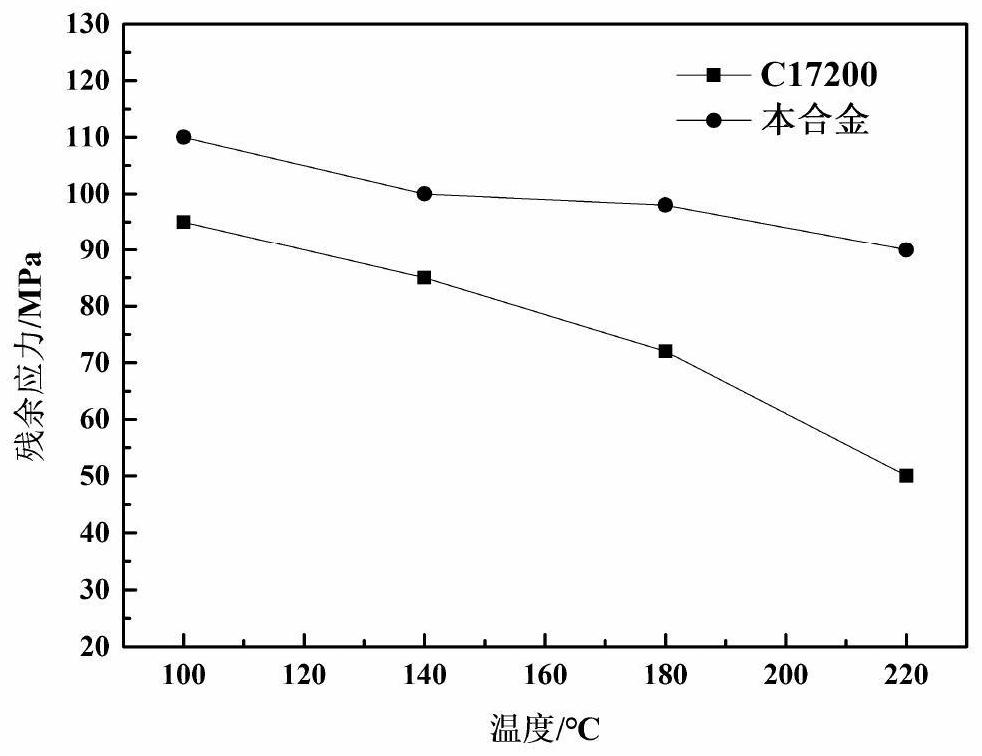

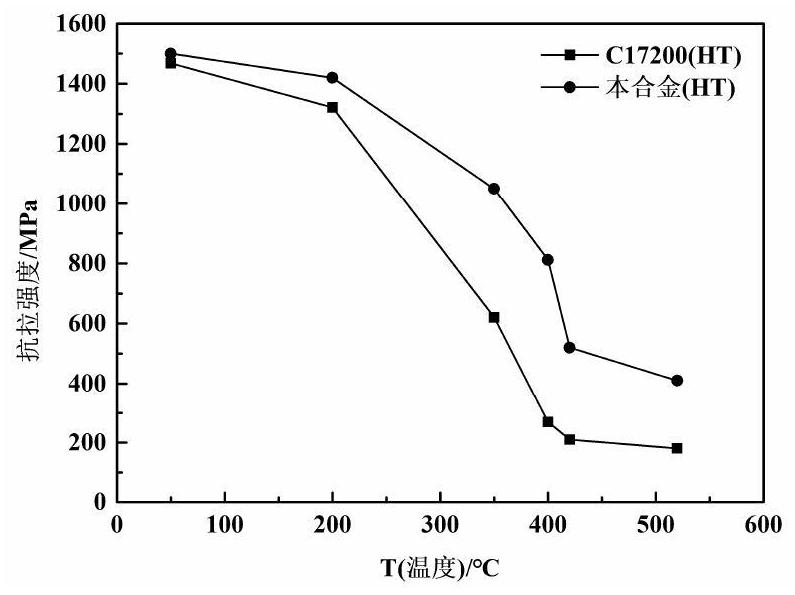

A beryllium-copper alloy and stress relaxation technology, which is applied in the field of easy-turning beryllium-copper alloy preparation, can solve the problems of high temperature softening resistance and low stress relaxation resistance, achieve good high temperature stability, improve cutting performance, and maintain stress relaxation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] Below in conjunction with embodiment, further illustrate the present invention.

Embodiment 1

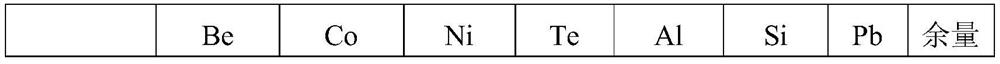

[0030] Preparation of beryllium copper tubes by extrusion

[0031] (1) Dosing according to the weight percentage in Table 1, the order of feeding is followed by cathode copper CATH-1, beryllium Be0.4wt.%, tellurium Te 0.35wt.%, Co+Ni is 2wt.%, Co+Ni+Fe is 2.05 wt.%, use 750Kg power frequency cored furnace non-vacuum induction furnace for melting, the melting temperature is 1170 ° C, after melting, keep warm for 15 minutes, pass in argon gas to remove impurities and gases, after degassing and removing impurities, let stand for 15 minutes, The ingot was prepared by vacuum spray deposition under a low-pressure argon protective atmosphere; the argon pressure was 0.1Pa, the deposition roller speed was 800r / min, and an ingot with a diameter of 75mm and a height of 300mm was prepared;

[0032] (2) The round ingot is hot-extruded at a temperature of 910°C, the extrusion ratio is 53:1, the extruder is a 2150T double-action horizontal extruder, and a tube blank with an outer diameter of...

Embodiment 2

[0043] Preparation of Beryllium Copper Rods

[0044] (1) carry out batching according to table 4 weight percent, raw material is cathode copper CATH-1, copper-beryllium master alloy (containing beryllium 10%), copper-tellurium master alloy (containing tellurium 10%), copper-nickel master alloy (containing nickel 10%) ), copper-cobalt master alloy (containing 10% cobalt); feed intake twice;

[0045] First add cathode copper CATH-1, copper-tellurium master alloy (containing 10% tellurium), copper-nickel master alloy (containing 10% nickel), copper-cobalt master alloy (containing 10% cobalt), and use a feeding device to add copper-tellurium master alloy after melting Alloy (containing 10% tellurium), copper-beryllium master alloy (containing 10% beryllium), heat up to 1270°C after melting, keep warm for 15 minutes after melting, pass in argon gas to remove impurities and gases, after degassing and removing impurities, let stand for 15 minutes ;

[0046] The ingot is prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com