Hydraulic and battery integrated vehicle composite energy system and control method thereof

A composite energy, electro-hydraulic control technology, applied in electric braking systems, electric vehicles, control drives, etc., can solve the problems of limited improvement of vehicle energy-saving effect, low braking energy recovery ratio, and low energy recovery efficiency, etc. To achieve the effect of improving vehicle economy, excellent power, and improving drivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

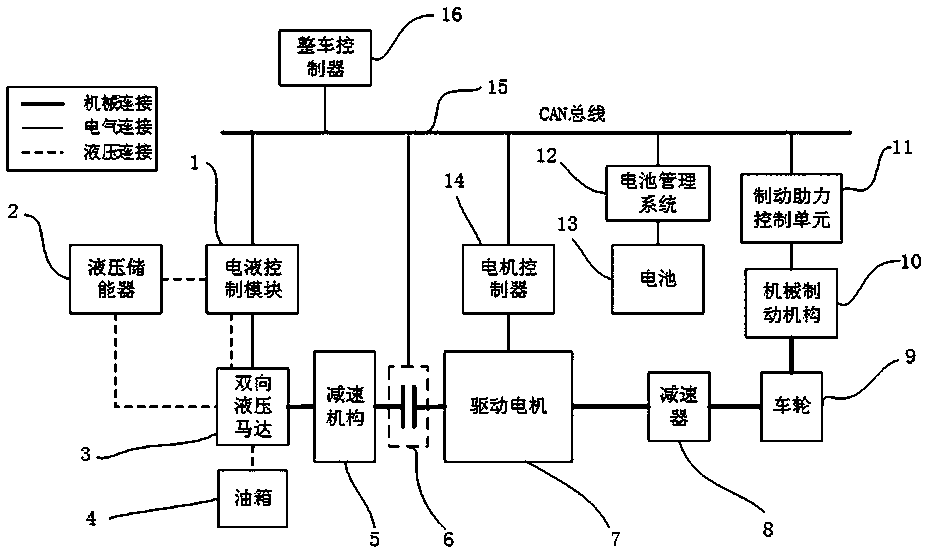

[0032] The vehicle composite energy system integrating hydraulic power and battery of the present invention includes a hydraulic accumulator 2, an electro-hydraulic control module 1, a bidirectional hydraulic motor 3, a speed reduction mechanism 5, a clutch 6, a drive motor 7, a battery 13, and a motor controller 14 And battery management system 12, brake booster control unit 11, CAN bus 15, vehicle controller 16;

[0033] The output shaft of the bidirectional hydraulic motor 3 is connected to one end of the rotor of the drive motor 7 through the reduction mechanism 5 and the clutch 6 , and the other end of the rotor of the drive motor 7 is connected to the wheel 9 through the reducer 8 . The two oil inlets of the bidirectional hydraulic motor 3 are respectively connected to the oil tank 4 and the hydraulic accumulator 2, the oil inlet of the hydraulic accumulator 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com