Air-locking feeder of moisture-containing raw material

A technology of air lock feeder and wet raw materials, which is applied in the direction of conveyors, conveyor objects, rotary conveyors, etc., and can solve the problem of not having the function of cleaning adhesive materials, high manufacturing requirements, poor feeding reliability and accuracy and other problems, to achieve the effect of solving the problem of air lock and feeding, ensuring thermal efficiency, and being economical and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

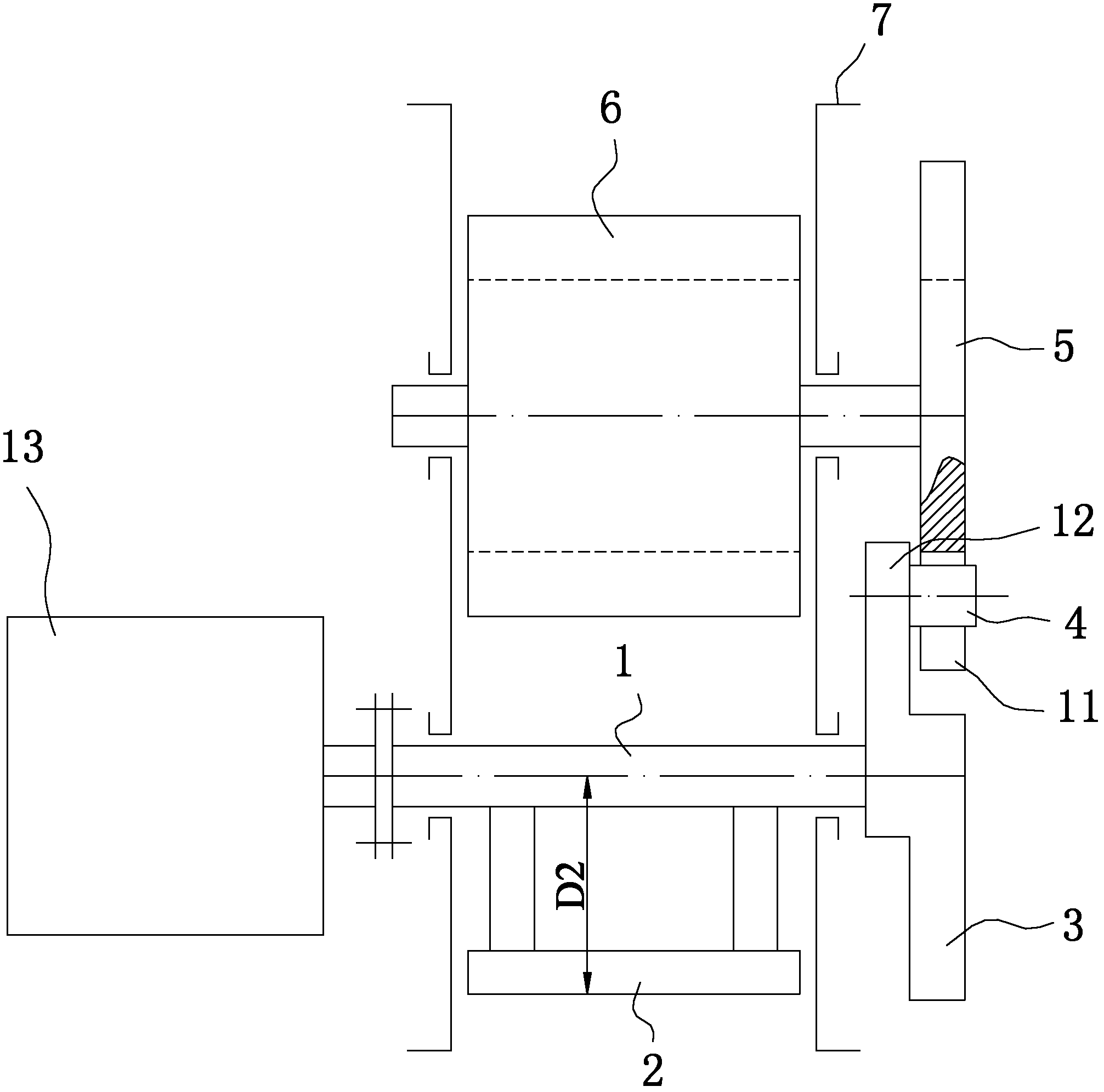

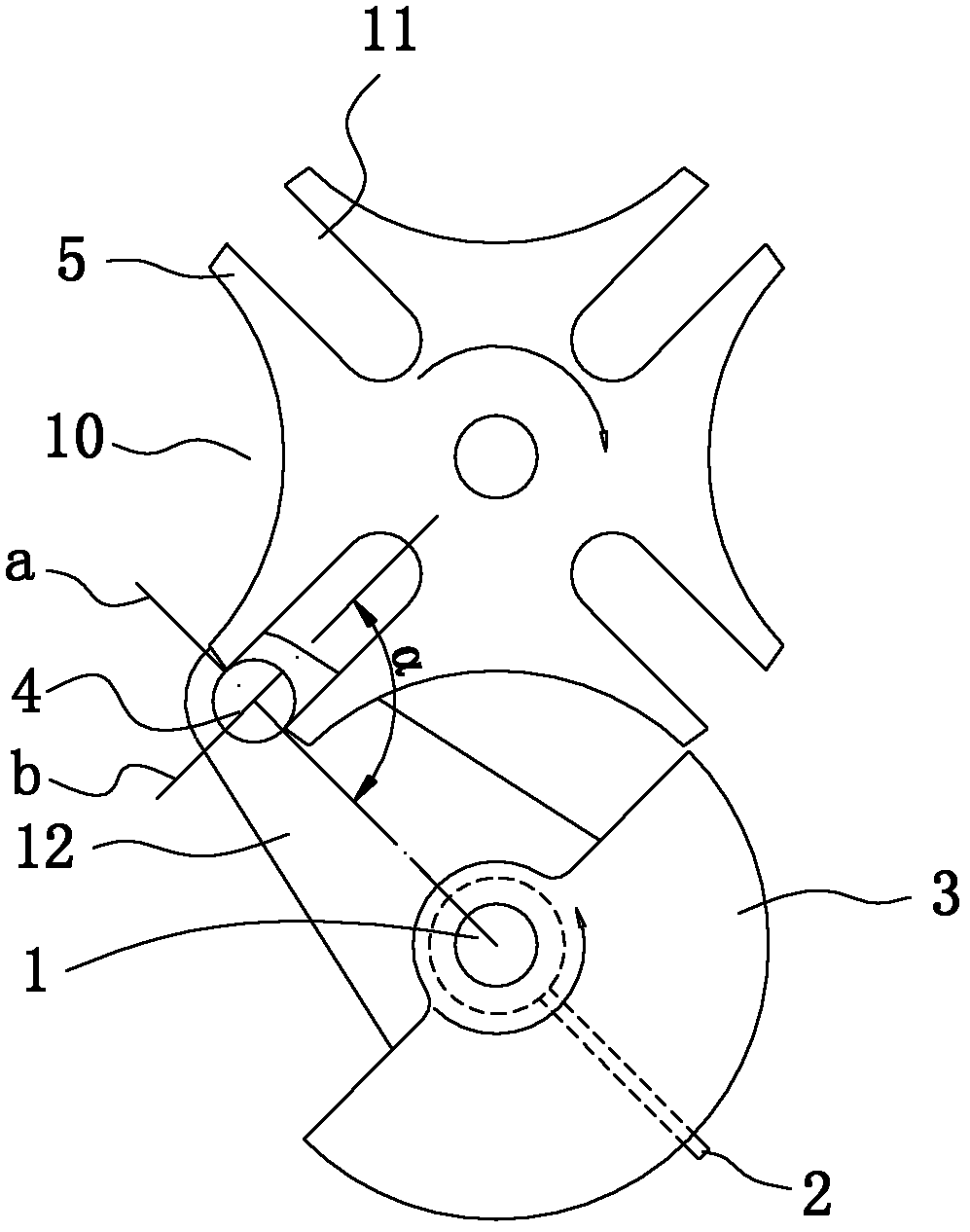

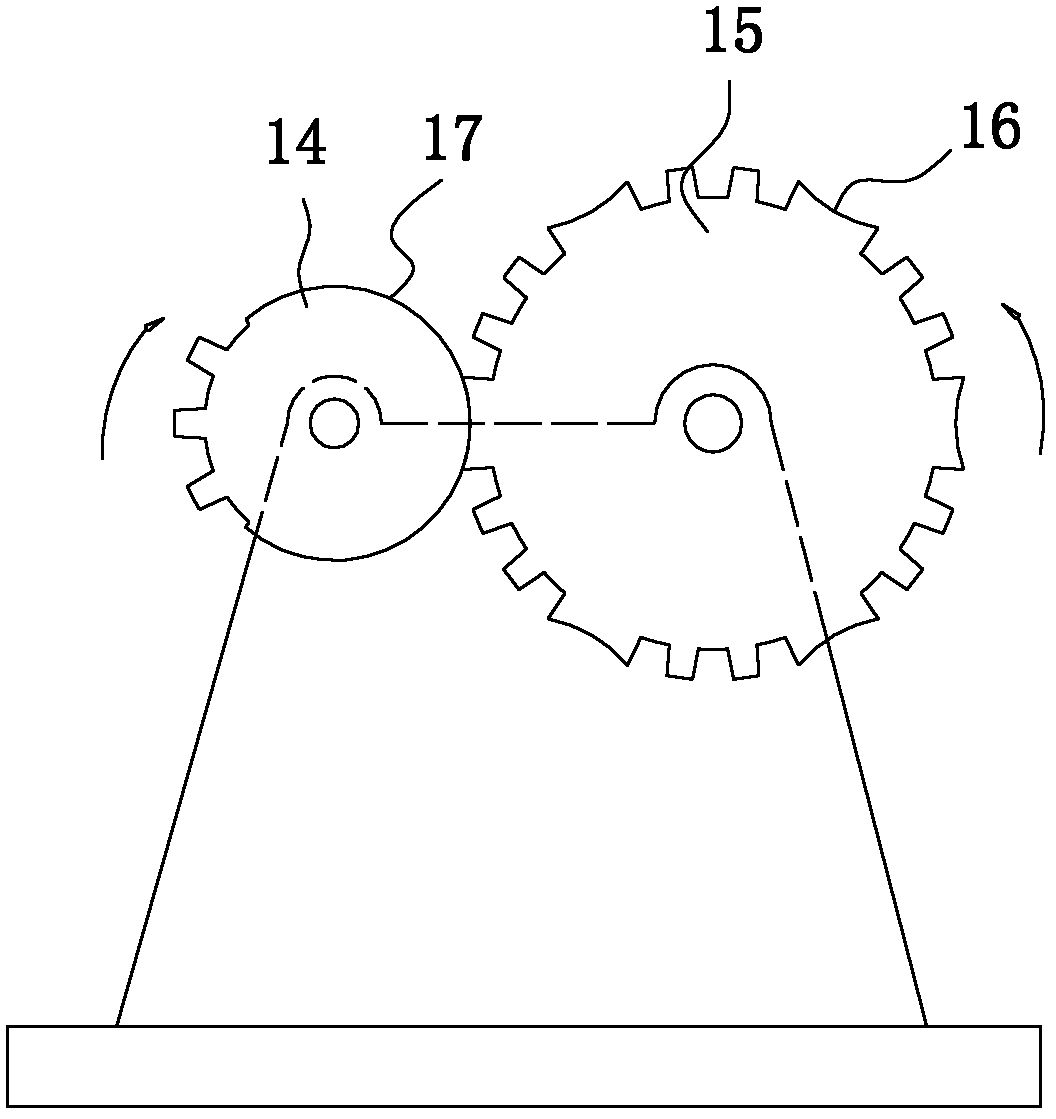

[0022] Such as Figure 1 to Figure 5 As shown, the wet raw material air lock feeder of the present invention includes a housing 7 with a feed inlet and a discharge outlet and a feed impeller 6 arranged in the housing 7, and the feed impeller 6 has a plurality of Uniformly distributed concave feeding area 8, the inner wall of the housing 7 has an arc surface structure 9, the center of the arc surface structure 9 coincides with the axis line of the feeding impeller 6, and the outer peripheral surface of the feeding impeller 6 The distance to the center of the feeding impeller 6 is D1, which is compatible with the radius of the arc surface structure 9, and the two sides of the feeding impeller 6 are matched with the inner wall of the housing 7, and are arranged in the housing 7. There is a bonding material cleaning device to prevent wet raw materials from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com