Use method of monascus in sesame-flavor liquor processing

A technology of sesame-flavored and red yeast rice, which is applied in the field of brewing and red yeast rice application in brewing, can solve the problems of waste of raw materials, low utilization rate of raw materials, non-uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

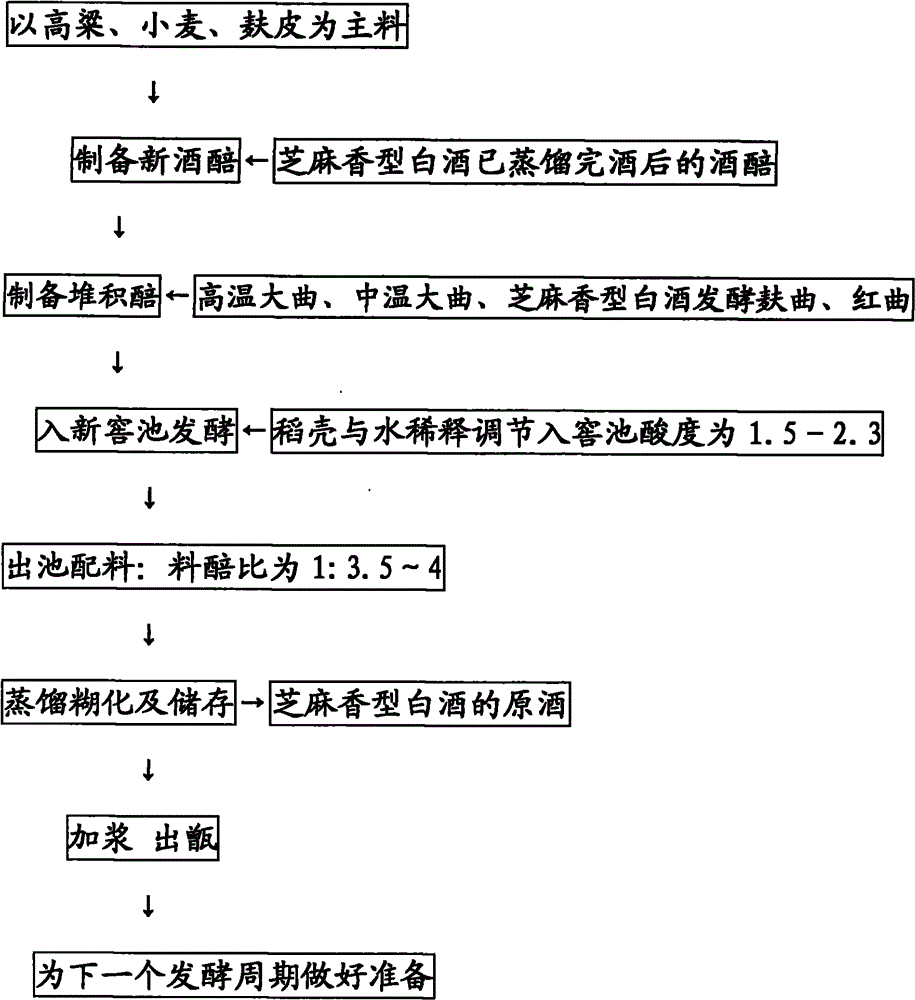

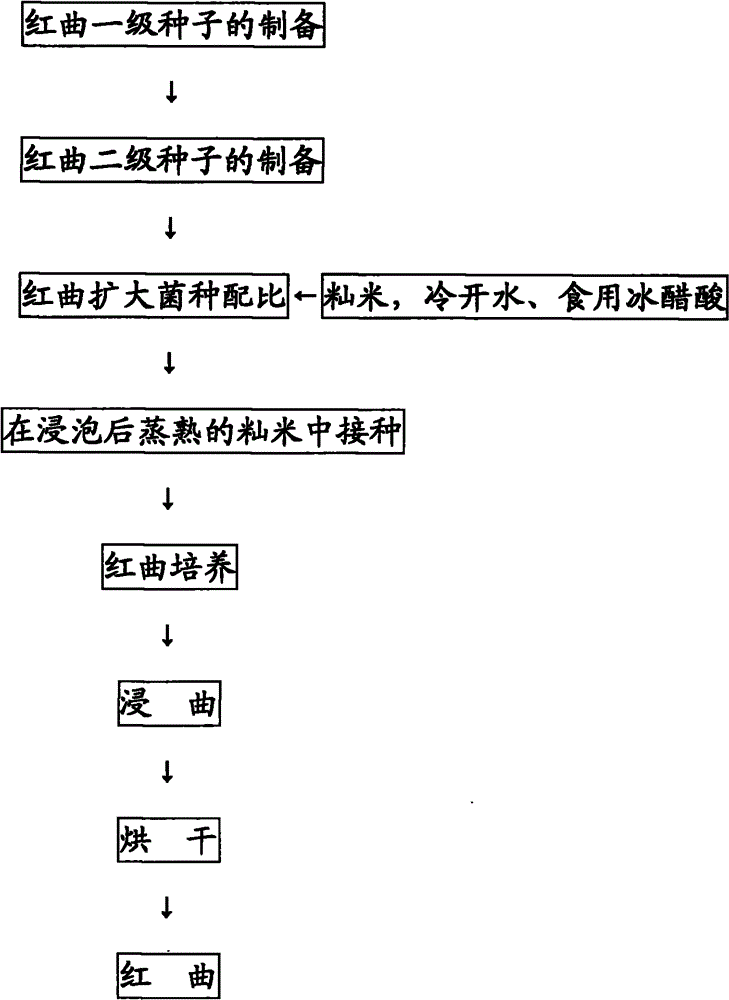

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification. As the instructions are attached figure 1 , 2 Shown:

[0047] A method for using red yeast rice in sesame-flavored liquor technology,

[0048] (1) Preparation of red yeast rice:

[0049] ① Preparation of the first-level seeds of red yeast rice: After heating and dissolving with 100ml of 6-10°Be' syrup solution, 5g of soluble starch, 3g of peptone, and 3g of agar, add 0.2ml of edible glacial acetic acid and divide into test tubes. , Each test tube is filled with 10ml, 0.1Mpa 30 minutes sterilization, made into inclined plane culture medium; insert AS3.554 strain into the made inclined plane medium, and place it in 28-30℃ incubator for 14-20 days ; Prepared into the first-level seeds of red yeast rice cultured on the slope of the test tube for later use;

[0050] ② Preparation of red yeast secondary seeds: Put 1 / 4 height of steamed indica rice in a large t...

specific Embodiment approach 2

[0071] Based on the implementation of specific implementation mode 1, as attached figure 2 As shown, the preparation of red yeast rice was carried out separately, namely: the preparation of red yeast rice first-level seeds, the preparation of red rice second-level seeds, the expansion of the red yeast rice strain ratio, and the preparation of inoculation into the steamed indica rice after soaking The red yeast rice bag to be cultivated, the red yeast rice is cultivated to obtain the mature rice red yeast rice, the wet red yeast rice is obtained by soaking the koji, and the red yeast rice is obtained by drying; the moisture of the prepared red yeast is 12% by the drying method. Below, 1g of absolute dried koji decomposes soluble starch at 35°C, pH 4.6, and 60 minutes into milligrams of glucose-the saccharification power activity is more than 800 units, and 1 g of absolute dried koji is hydrolyzed at 40°C, pH 3.0, and cheese per minute. The protein is the number of micrograms of...

specific Embodiment approach 3

[0072] Based on the implementation of specific implementation mode 1, as attached figure 1 As shown, the red yeast rice prepared in the second embodiment is used to produce sesame-flavored liquor, that is, sorghum, wheat, and bran are used as main materials, and the distilled mash is mixed to prepare a new mash, and High-temperature Daqu, medium-temperature Daqu, and sesame-flavored white wine fermented bran koji, the new red koji is mixed and cultured to prepare a pile of mash, and the steamed rice husk and water are added to adjust the acidity to 1.5-2.3 into the mud bottom red strip stone wall fermentation The pit is fermented. After fermentation, the ingredients are distilled and gelatinized to obtain the sesame-flavored liquor. The raw wine is classified into the warehouse and stored separately. After that, the mash after the distilled wine is dried through ventilation, slagging, and The temperature is lowered, the required water is supplemented, and the main ingredients ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com