Transmission pump and filter

A technology of filters, filter assemblies, applied in the direction of components, pumps, pump elements, etc. of pumping devices for elastic fluids, capable of solving problems such as noise, unpleasantness, pump damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

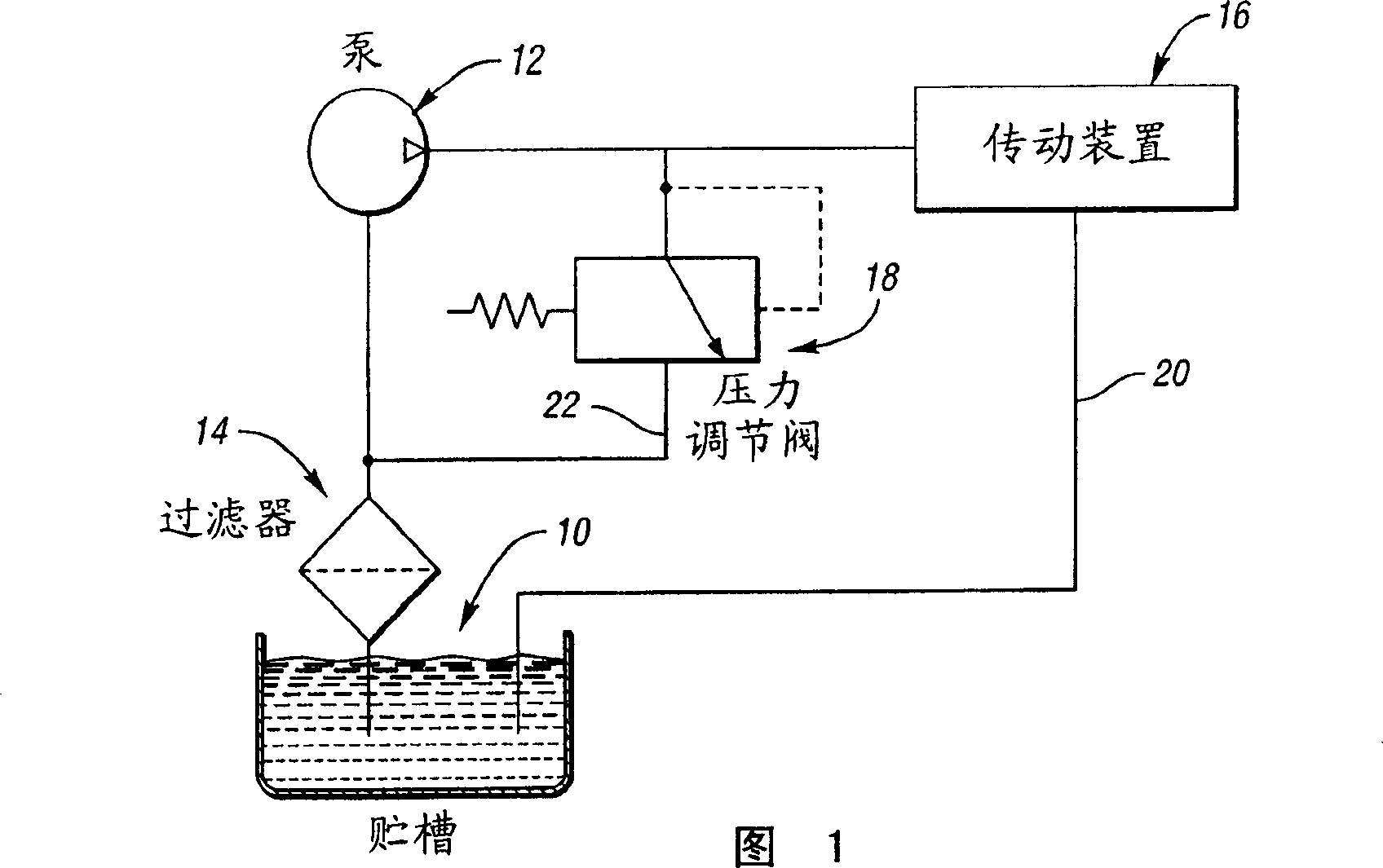

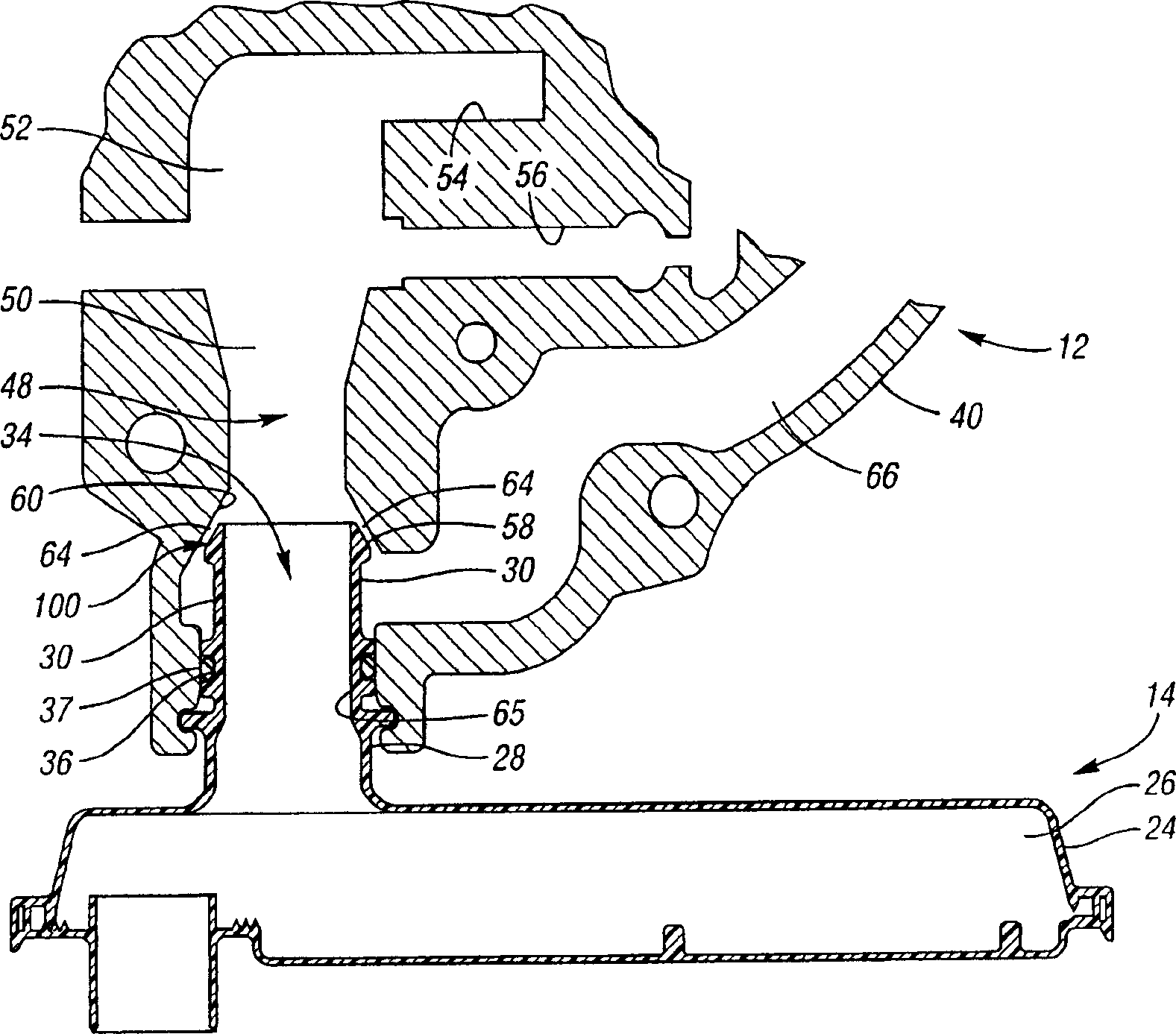

[0010] Referring to the drawings, in which like numerals indicate like or corresponding parts in the various figures, there can be seen in FIG. 1 a schematic representation of a tank or container 10 containing hydraulic fluid. The transmission controls the pump 12 to draw fluid from the container 10 through the filter assembly 14 . Pump 12 outputs pressurized hydraulic fluid to transmission system 16 . The maximum pressure at the pump output port is determined by the pressure regulator valve 18 which sends excess pump flow to the filter 14 . In accordance with a preferred embodiment of the present invention, the fluid first meets the transmission lubrication and pressure requirements, then the torque converter pressure requirements, then provides some lubrication and cooling, after which excess fluid is returned to the filter assembly 14 .

[0011] Lubrication flow and leakage fluid in the transmission system 16 returns to the container 10 through passages such as 20 . Exces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com