Flame center controllable coal pulverizing system mill dislocation pulverized coal pipeline arrangement structure

A technology of pulverized coal pipeline and pulverizing system, which is applied in the field of boilers, can solve problems such as changes in the center of the boiler flame, and achieve the effects of stable combustion and improved fullness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

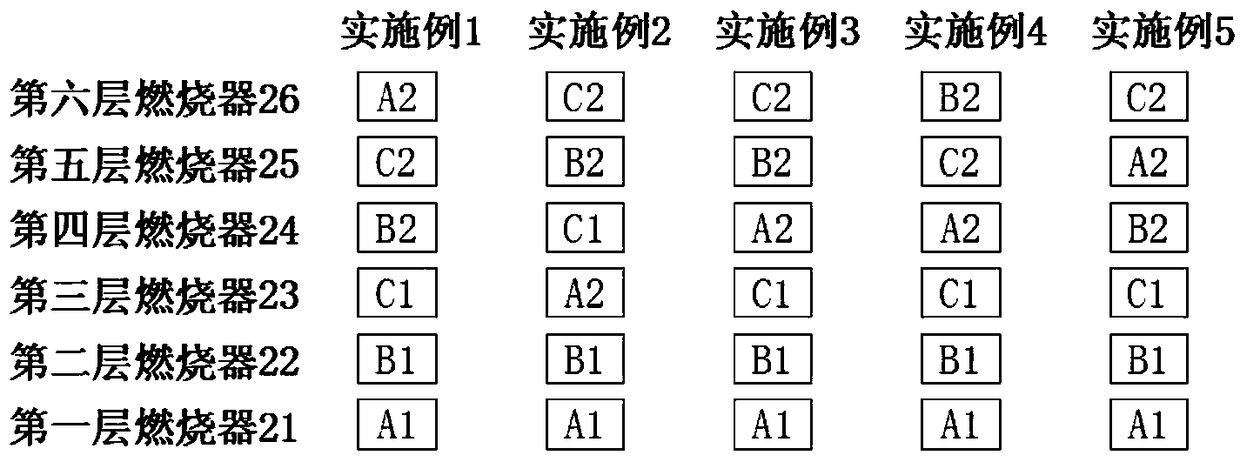

Embodiment 1

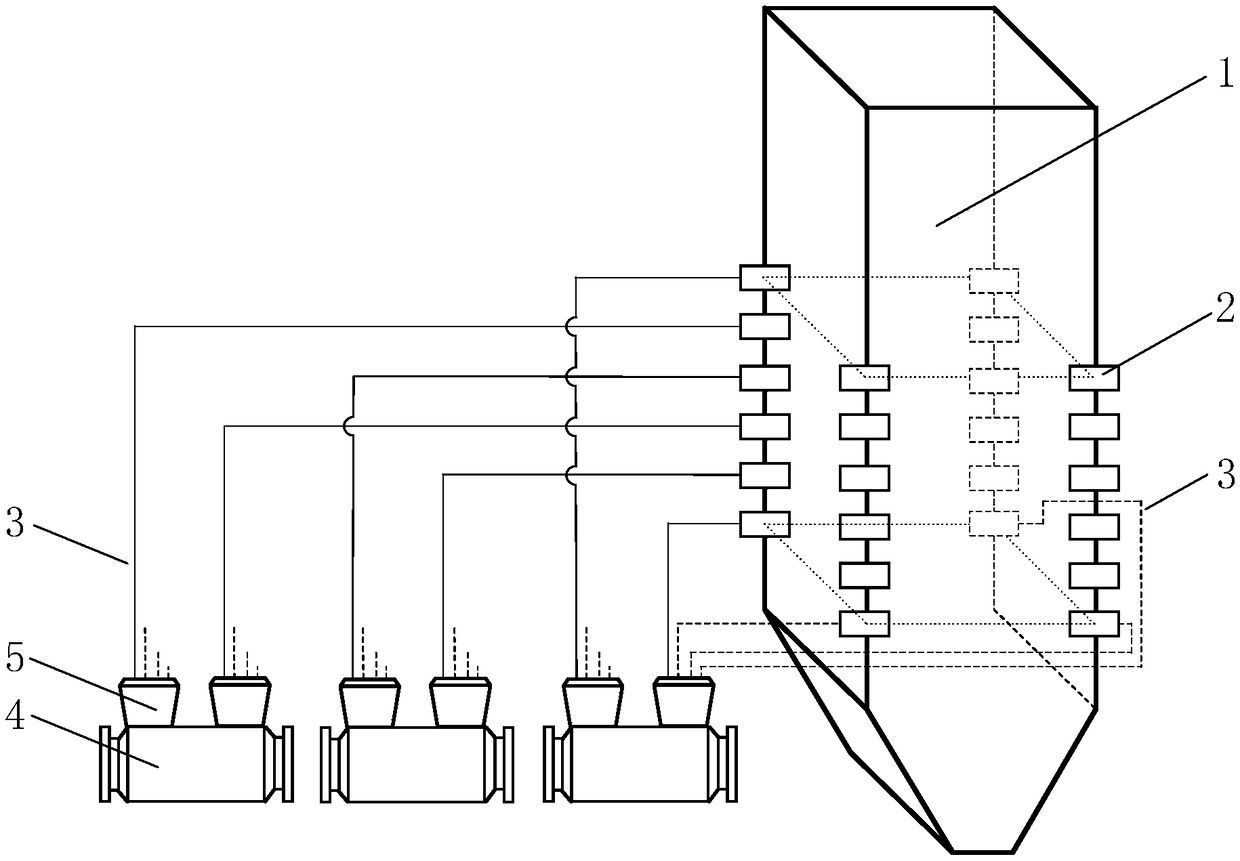

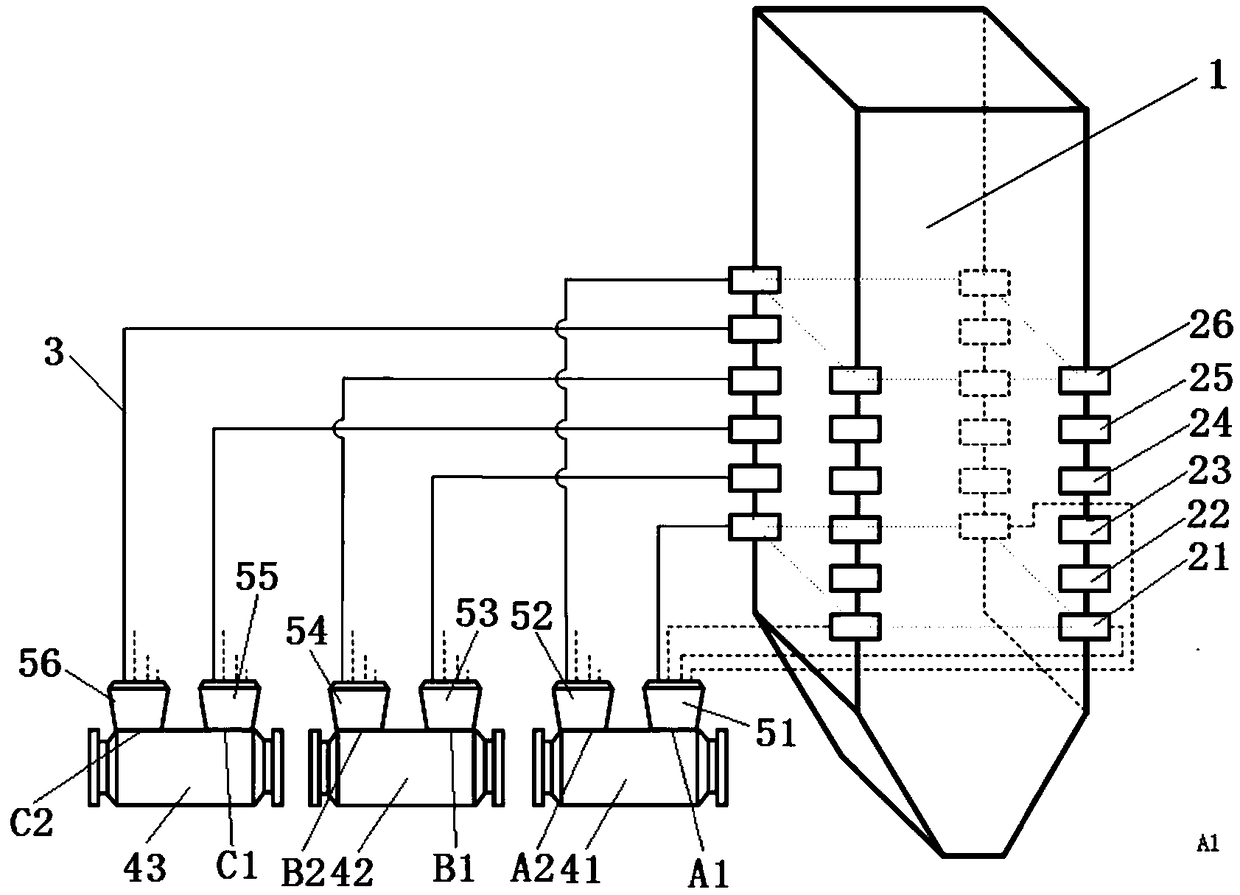

[0029] See attached figure 2 , 3 As shown, the first outlet A1 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the first pulverized coal separator 51, and the outlet of the first pulverized coal separator 51 passes through the pulverized coal pipeline 3 They are respectively connected to the first layer of burners 21; the second outlet A2 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the second pulverized coal separator 52, and the outlet of the second pulverized coal separator 52 The feed port is respectively connected to the sixth layer burner 26 through the pulverized coal pipeline 3;

[0030] The first outlet B1 of the second double-inlet and double-outlet coal mill 42 is connected to the inlet of the third pulverized coal separator 53, and the outlet of the third pulverized coal separator 53 is respectively connected to the first outlet of the pulverized coal separator 53 through the pulverize...

Embodiment 2

[0034] See attached figure 1 , 3 As shown, the first outlet A1 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the first pulverized coal separator 51, and the outlet of the first pulverized coal separator 51 passes through the pulverized coal pipeline 3 They are respectively connected to the first layer of burners 21; the second outlet A2 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the second pulverized coal separator 52, and the outlet of the second pulverized coal separator 52 The feed port is respectively connected to the third layer burner 23 through the pulverized coal pipeline 3;

[0035]The first outlet B1 of the second double-inlet and double-outlet coal mill 42 is connected to the inlet of the third pulverized coal separator 53, and the outlet of the third pulverized coal separator 53 is respectively connected to the first outlet of the pulverized coal separator 53 through the pulverized ...

Embodiment 3

[0038] See attached figure 1 , 3 As shown, the first outlet A1 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the first pulverized coal separator 51, and the outlet of the first pulverized coal separator 51 passes through the pulverized coal pipeline 3 They are respectively connected to the first layer of burners 21; the second outlet A2 of the first double-inlet and double-outlet coal mill 41 is connected to the inlet of the second pulverized coal separator 52, and the outlet of the second pulverized coal separator 52 The feed port is respectively connected to the fourth layer burner 24 through the pulverized coal pipeline 3;

[0039] The first outlet B1 of the second double-inlet and double-outlet coal mill 42 is connected to the inlet of the third pulverized coal separator 53, and the outlet of the third pulverized coal separator 53 is respectively connected to the first outlet of the pulverized coal separator 53 through the pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com