Moving cylinder efficient tubular oil pump

A high-efficiency pipe and oil well pump technology, which is applied in the direction of pumps, machines/engines, and liquid displacement machinery, etc., can solve the problems of increasing the leakage of oil inlet valves, large liquid resistance, and reduced pump efficiency, so as to increase the effective stroke , Reduce the downward bending, the effect of small oil inlet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing:

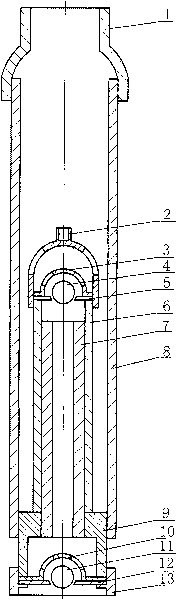

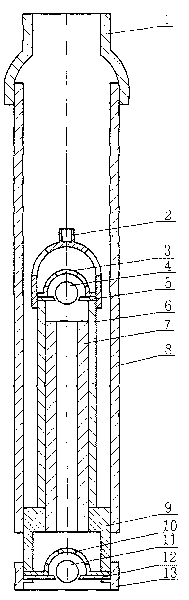

[0008] As shown in the figure, 1 is the upper joint of the pump body, 2 is the upper joint of the pump barrel, 3 is the oil outlet valve cover, 4 is the oil outlet valve ball, 5 is the oil outlet valve seat, 6 is the pump barrel, and 7 is the Plunger, 8 are outer pipes, 9 are plunger seats, 10 are oil inlet valve covers, 11 are oil inlet valve balls, 12 are oil inlet valve seats, and 13 are oil inlet valve joints.

[0009] The oil inlet valve is composed of an oil inlet valve seat 12, an oil inlet valve cover 10, and an oil inlet valve ball 11; the oil outlet valve is composed of an oil outlet valve seat 5, an oil outlet valve cover 3, and an oil outlet valve ball 4 composition.

[0010] When the pump barrel 6 goes up, the oil inlet valve is opened and the oil outlet valve is closed, and the liquid enters the pump chamber, and at the same time, the liquid discharged from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com