A kind of sewing method of sleeve and armband lining for preventing cuff lock

A technology of cuff strips and cuff locks, which is applied in the field of sewing sleeves and cuff liners to prevent cuff locks, which can solve the problems of difficult operation, low efficiency, and unguaranteed appearance quality of suits, etc., and reduce the difficulty of operation , reduce production costs, and promote the effect of using value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

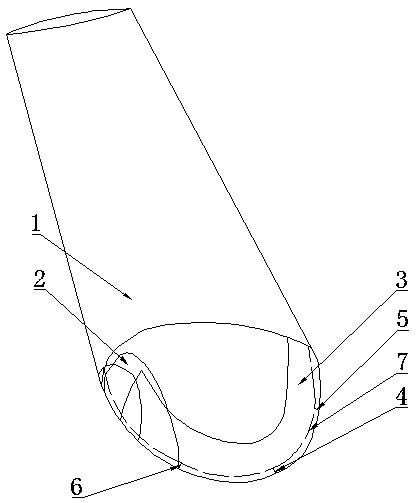

[0019] as attached figure 1 Shown, the sewing method that the sleeve of the present invention prevents cufflock and armband liner is integrated, this method comprises the steps:

[0020] (1), a sleeve incision is made on the sleeve piece, and a knife edge corresponding to the sleeve incision is opened on the front sleeve lining 2 of the armband lining. The front incision 6 of the lining and the rear incision 5 of the sleeve lining; after the three incisions on the front sleeve lining 2 are aligned with the sleeve incisions, the front sleeve lining 2 is directly bonded to the sleeve piece with water-based PVC patch glue;

[0021] (2) Use the seam line 7 to place the sleeve strip 3 of the sleeve liner on the upper layer of the front sleeve liner 2 in step (1) according to a seam allowance of 0.5 cm, and sew it together with the front sleeve line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com