Sand-preventing scale-preventing oil well pump with long plunger piston

A long plunger, oil well pump technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of oil well pump leakage failure, valve ball can not be set, oil well pump failure, etc., to extend the pump inspection cycle , Prevent the plunger from being stuck, and improve the effect of pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

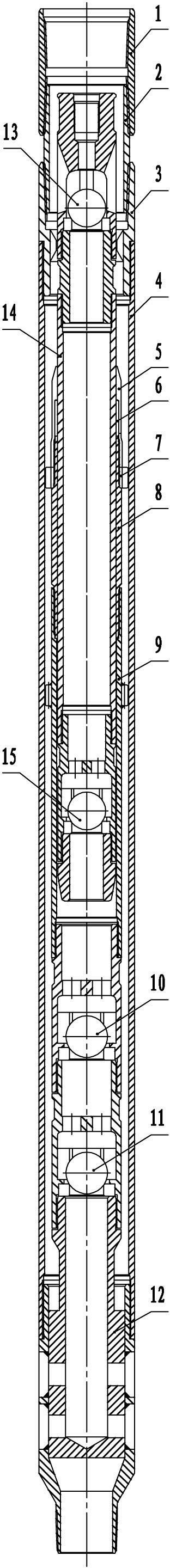

[0024] The long plunger 14 is installed in the short pump barrel 8 and the pump barrel extension 9, and the short pump barrel 8 and the pump barrel extension 9 are also equipped with a sand settling pipe 4, and the lower end of the pump barrel extension 9 is provided with at least one One-way valve; the optimal solution is to provide a first fixed valve 10 and a second fixed valve 11 at the lower end of the pump barrel extension tube 9 .

[0025] The upper end of the sand settling pipe 4 is connected with the oil pipe collar 1 through the righting coupling 3 and the extension nipple 2, and the lower end of the sand settling pipe 4 is connected with the double-way joint 12;

[0026] The two ends of the long plunger 14 are provided with a first traveling valve 13 and a second traveling valve 15 .

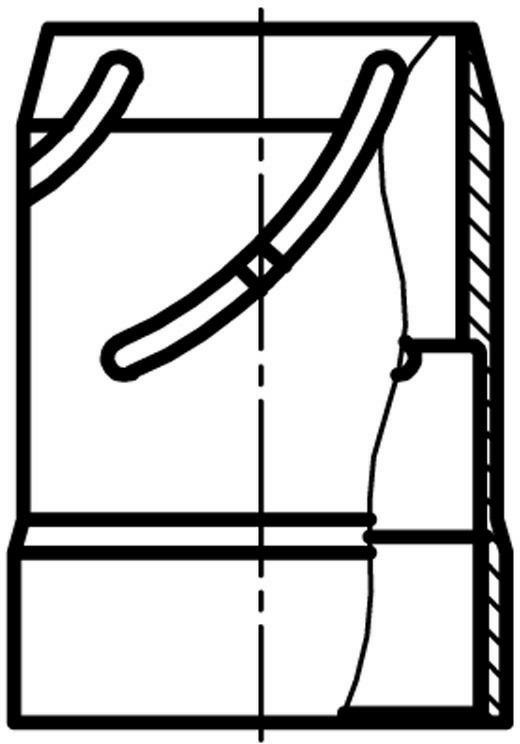

[0027] A spacer ring 6 is arranged inside the scraper ring 5 . The isolating ring 6 is made of composite materials, such as bronze-based polytetrafluoroethylene, graphite and / or wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com