Raw oil lifting system and method for conveying fluid by utilizing sliding vane pump

A technology for transporting fluid and sliding vane pumps, which is applied in the direction of mining fluids, pumps, pump components, etc., can solve the problems of large radial size and small lifting force of sliding vane pumps, and achieve the reduction of radial size and radial volume, High lifting capacity, effect of increasing application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

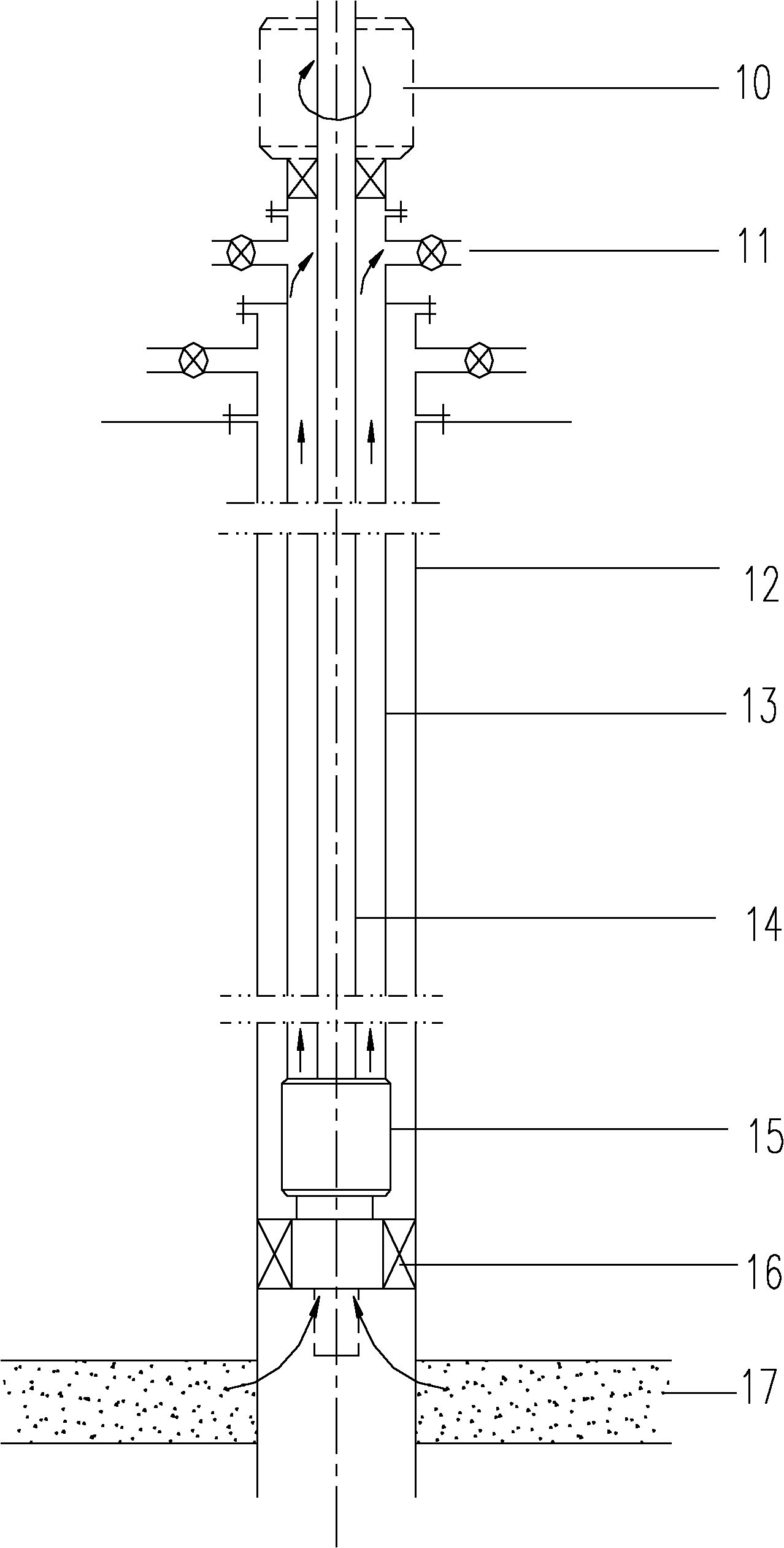

[0037] Such as figure 1 As shown, the present invention proposes a crude oil lifting system for lifting crude oil in an oil well, and the crude oil lifting system includes: an oil pipe 13 arranged in an oil well casing 12, an oil pump connected to the oil pipe 13 , the oil well pump is a sliding vane pump 15.

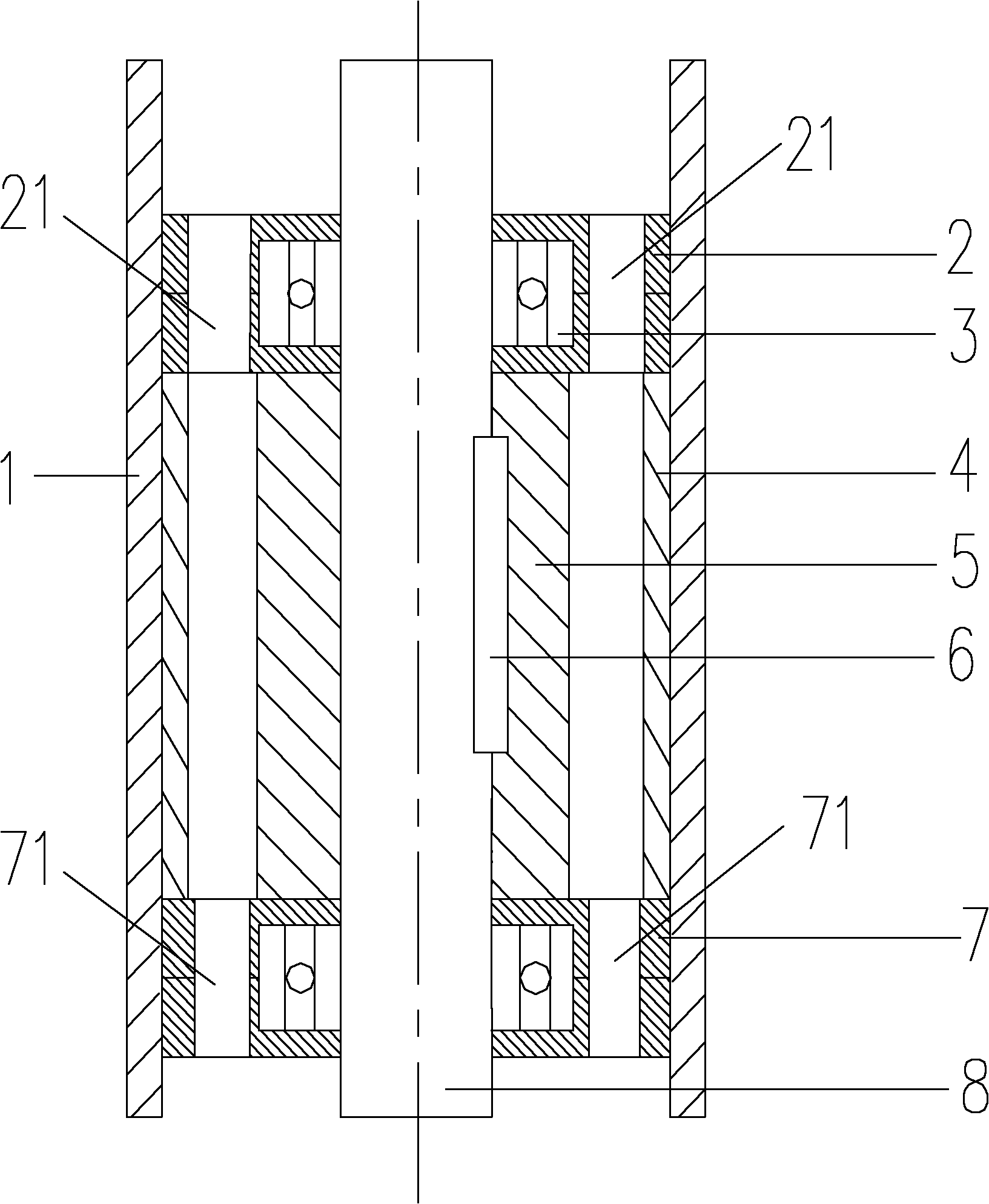

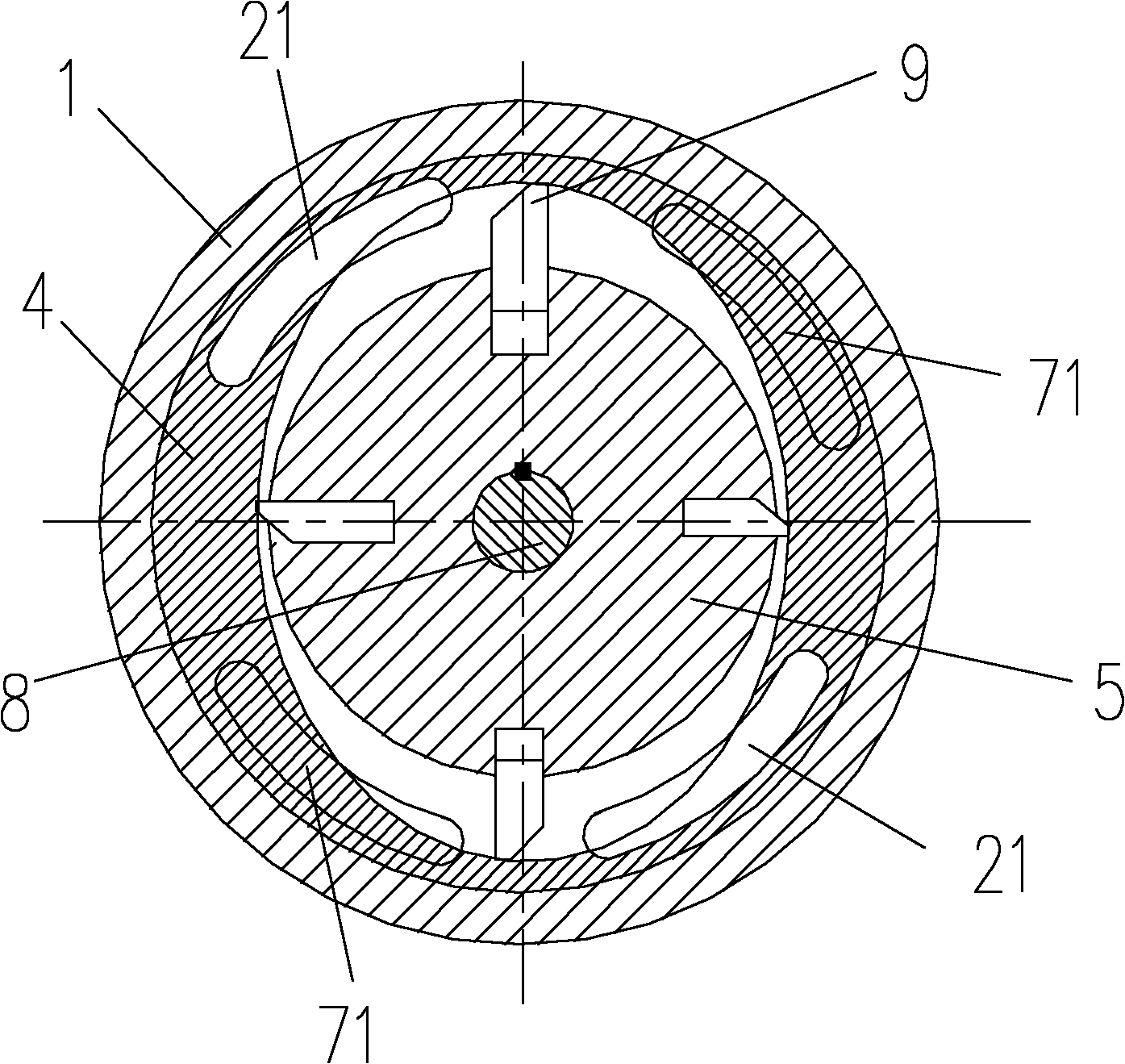

[0038] Such as figure 2 and image 3 As shown, the first sliding vane pump of the present invention has a cylindrical stator 4, and the stator 4 is provided with: a drive shaft 8 (also called a pump shaft), and the drive shaft 8 is parallel to the length of the stator 4 The direction is set in the rotor 5 in the stator 4 and sleeved on the drive shaft 8; the lower end of the stator 4 is provided with a suction disk 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com