Diaphragm pump with pressure regulating and one-way reverse osmosis functions

A technology of reverse osmosis and diaphragm pump, applied in the direction of pump with flexible working elements, pump, pump control, etc., can solve the damage of diaphragm pump, does not have the functions of pressurization, pressure regulation and one-way reverse osmosis, cannot solve the problem of diaphragm pump Outlet pressure problems and other problems, to achieve the effect of stable working pressure, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

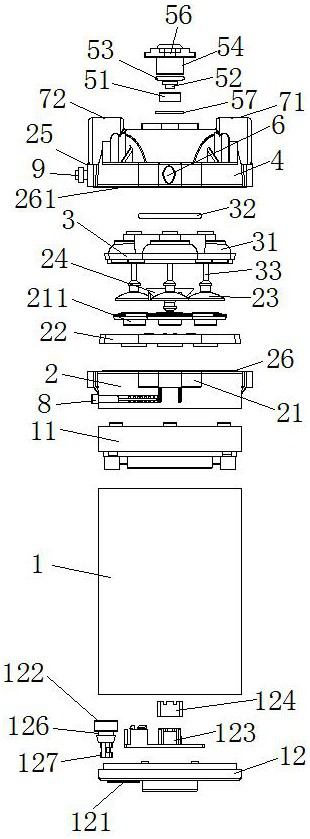

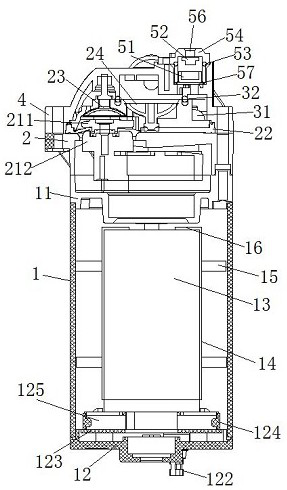

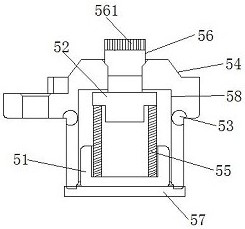

[0021] Figures 1 to 3 It is a structural representation of the present invention.

[0022] The reference signs therein are: pump body 1, first end cover 11, second end cover 12, outlet hole 121, outlet protective cover 122, carbon brush support frame 123, carbon brush buckle 124, carbon brush 125, anti-clip Groove 126, waterproof sealing tube 127, drive motor 13, limit structure 14, connecting rod 15, annular limit plate 16, support frame 2, eccentric balance wheel 21, piston piece 211, piston rod 212, diaphragm body 22, suction Check valve 23, discharge check valve 24, second support frame 25, annular card groove 26, annular bead 261, mounting bracket 3, diaphragm chamber 31, O-ring 32, hollow connecting rod 33, fluid chamber 4, regulator Pressure device 5, spring base 51, spring cover plate 52, top cover sealing ring 53, small top cover 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com