Lifting device of electric submersible piston pump in horizontal wells

A lifting device and plunger pump technology, applied in the direction of pumps, wellbore/well parts, pumps with flexible working elements, etc., can solve the problems of low production cost, prolonging the pump inspection period, and reducing the operation and maintenance workload of rod system factors and other issues to achieve the effect of adjusting the displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

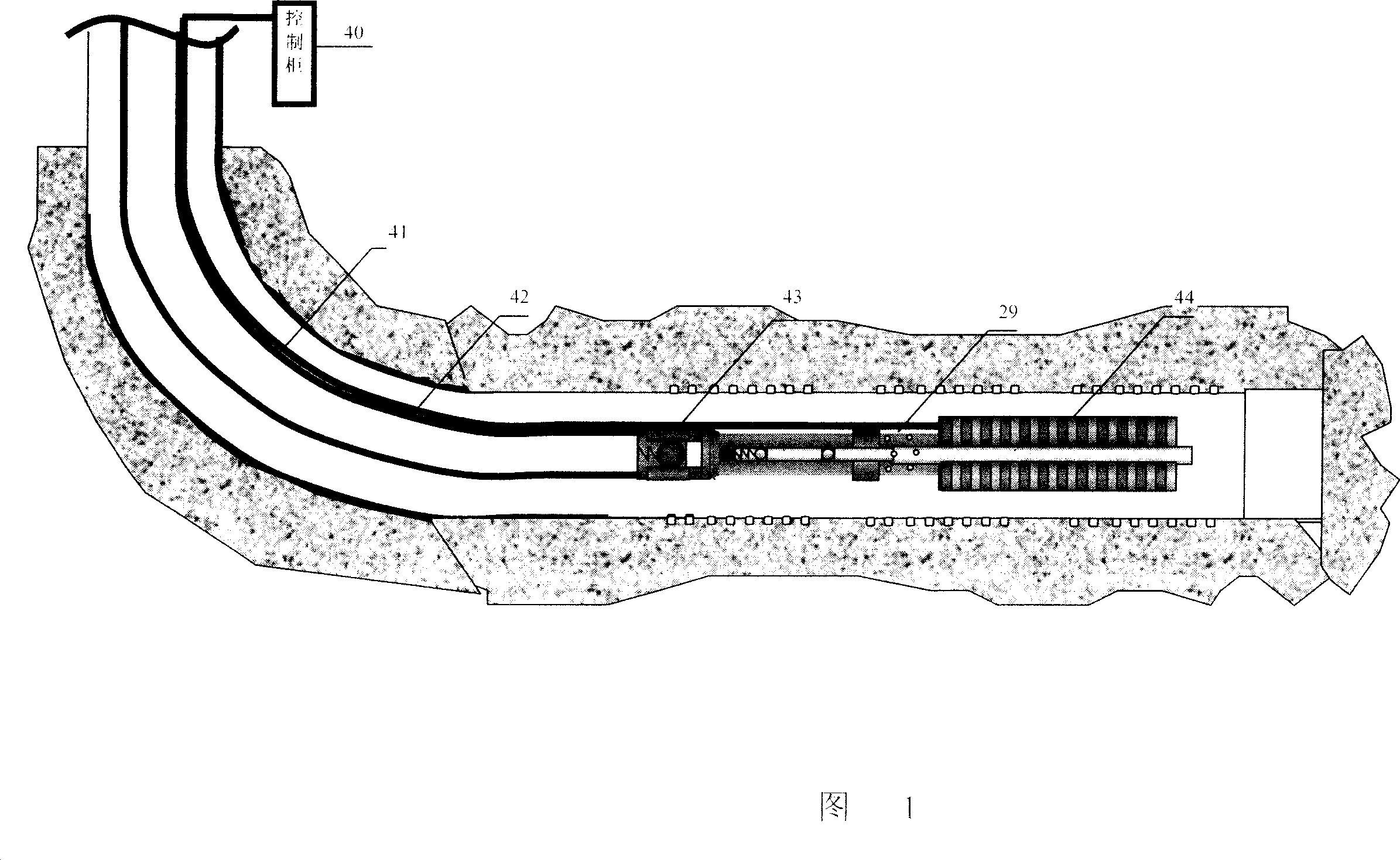

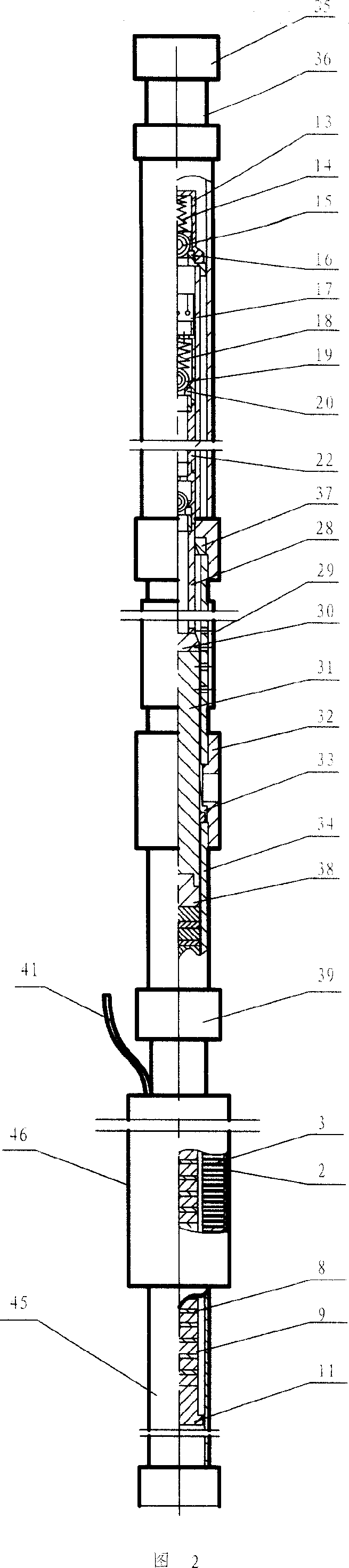

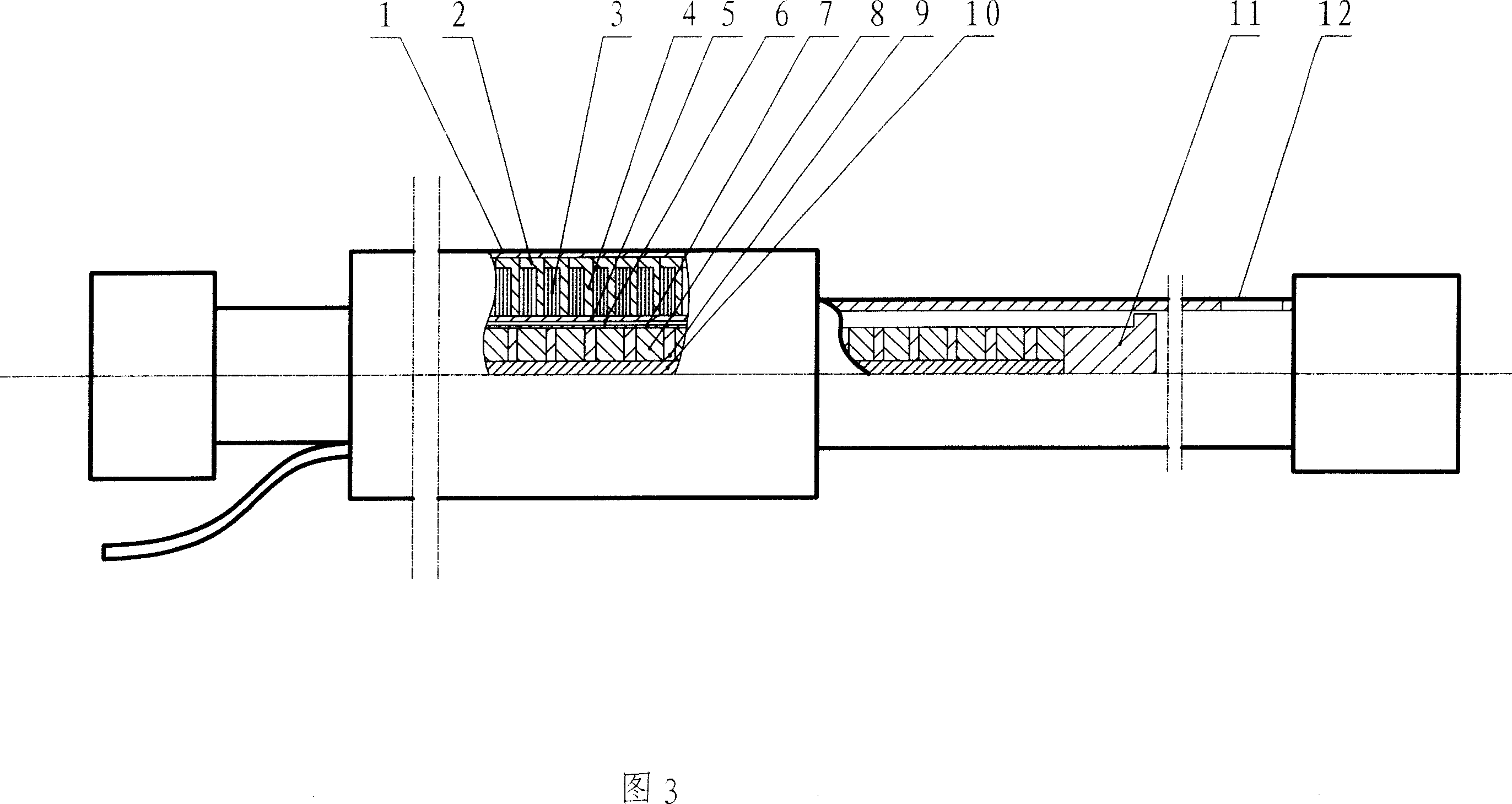

[0016] As shown in Figure 1, the electric submersible plunger pump lifting device of this kind of horizontal well includes a Christmas tree, oil pipe 42, submersible oil cable 41, ground frequency conversion control cabinet 40, small-diameter high-elastic permanent magnet linear motor 44, horizontal lifting The oil well pump 43 is connected by a small-diameter high-elastic permanent magnet linear motor 44 to the rear end of the horizontal lift oil well pump 43, and the front end of the horizontal lift oil well pump 43 is connected to the oil pipe 42, through the frequency conversion control cabinet on the ground 40. The submersible cable 41 provides electric energy for the small-diameter high-elastic permanent magnet linear motor 44 . The stator of the small-diameter high-elastic permanent magnet linear motor 44 is connected with the pump barrel of the horizontal lift oil w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com