Well-head hydraulic signal generating device and operating method thereof

A hydraulic signal and generating device technology, which is applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as difficulties, affecting production, inconvenient production adjustment measures, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

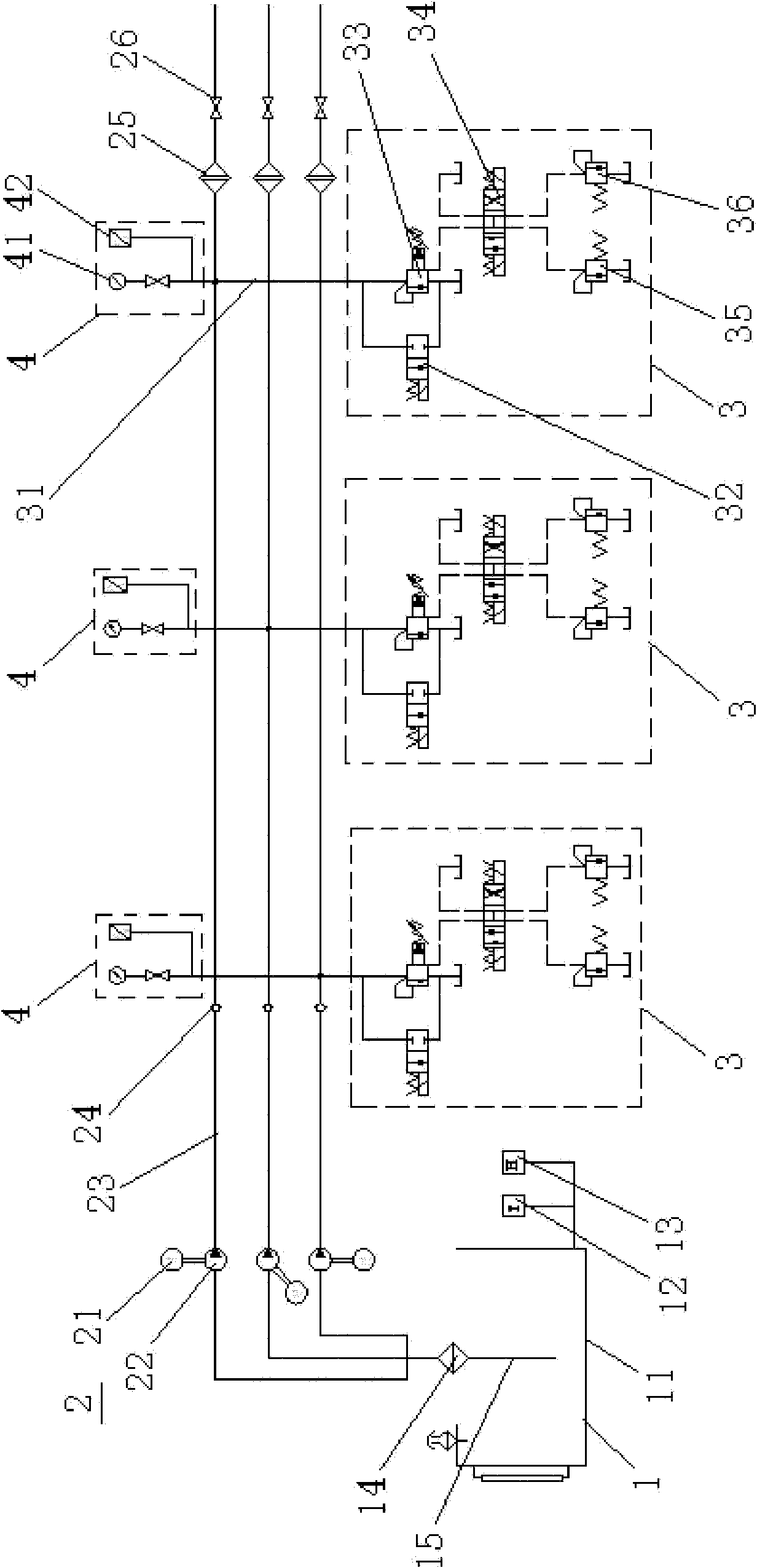

[0012] Such as figure 1 As shown, the present invention includes a hydraulic oil source 1 , a power unit 2 , a relief valve group 3 and a pressure testing system 4 .

[0013] The hydraulic oil source 1 includes a fuel tank 11, a temperature sensor 12 and a liquid level sensor 13 are arranged on the side wall of the fuel tank 11, and the output ends of the temperature sensor 12 and the liquid level sensor 13 are connected to a monitoring computer (not shown in the figure). An oil delivery pipeline 15 with a hydraulic oil filter 14 is arranged in the oil tank 11 , and the other end of the oil delivery pipeline 15 is connected to the power unit 2 . Clean hydraulic oil can be provided for the device of the present invention through the hydraulic oil source 1 .

[0014] The power unit 2 includes a hydraulic pump 22 driven by a variable frequency motor 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com