Sectional synchronous flow rate and water content monitoring and water exploration tubular column of multi-section fracturing horizontal well and working method thereof

A technology for a water-seeking string and a working method, which is applied in the fields of water-cutting and simultaneous monitoring of the water-seeking string, and multi-stage fracturing horizontal well segmented flow fields, which can solve the problem of unclear water breakthrough level and direction, unsuitable for water seeking needs, and affecting on-site production. progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

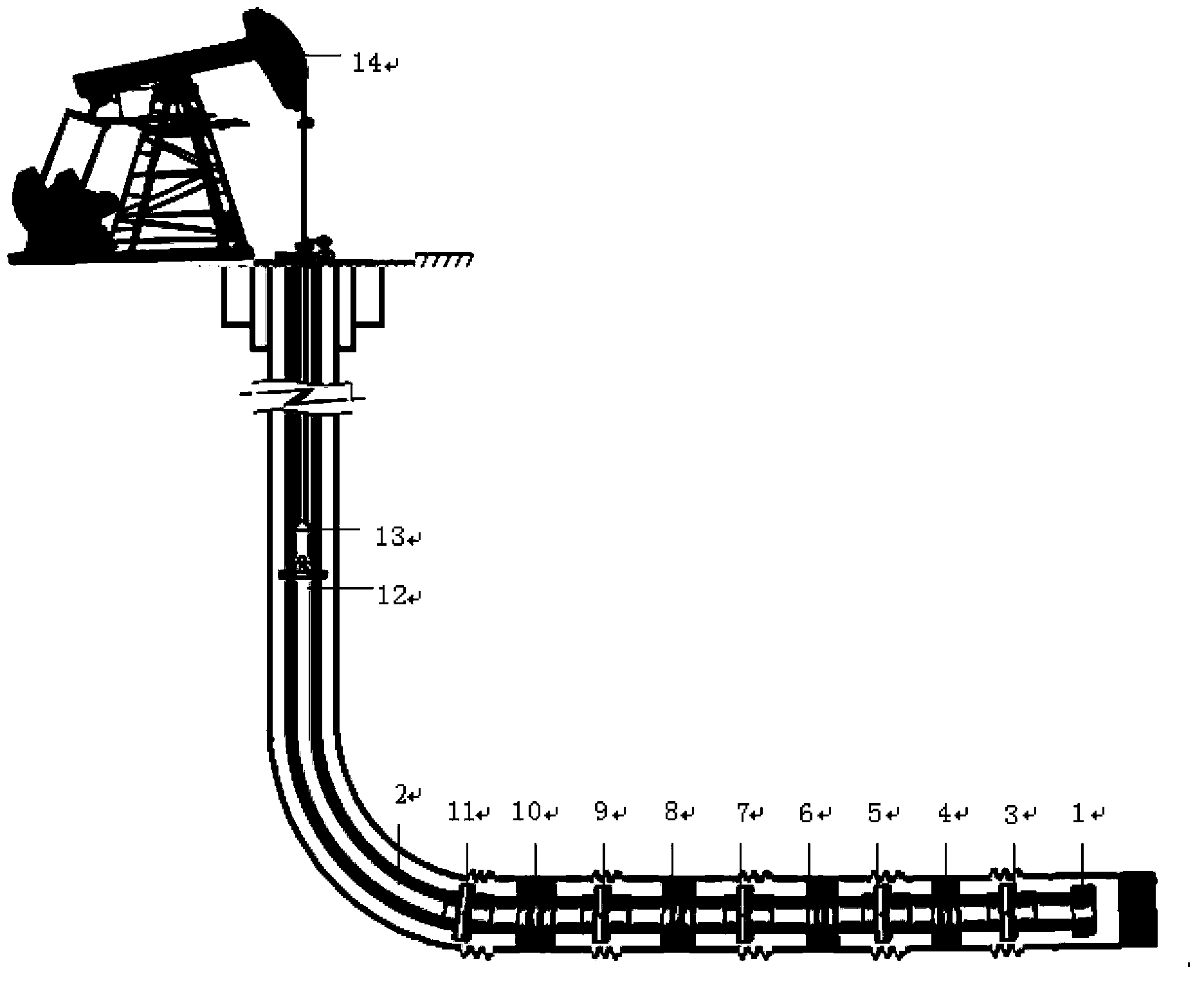

[0013] refer to figure 1 Embodiments of the present invention are further described:

[0014] The upper end of the tapered plug 1 of the tubing string is connected to the first-level downhole storage flow and water cut monitor 3 through the tubing 2, and the upper end of the first-level downhole storage flow and water cut monitor 3 is connected to the first-level packer 4 through the tubing 2, The upper end of stage I packer 4 is connected to stage II downhole storage flow and water cut monitor 5 through tubing 2, and the upper end of stage II downhole storage flow and water cut monitor 5 is connected to stage II packer 6 through tubing 2, and stage II packer The upper end of the device 6 is connected to the grade III downhole storage flow and water cut monitor 7 through the tubing 2, and the upper end of the III downhole storage flow and water cut monitor 7 is connected to the grade III packer 8 through the tubing 2, and the upper end of the grade III packer 8 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com