Multifunctional oil-extraction and gas-injection integrated oil well pump for sanding heavy crude oil well

A multi-functional, oil-pumping technology, applied in the fields of fluid production, pumping, and earth-moving drilling, etc., can solve the problems of increasing the workload of downhole operations, prolonging the construction operation period, and missing the period of transfer to oil production, so as to reduce the workload of operation, improve the Improve the effect of thermal recovery and stable production, and solve the problem of sand production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

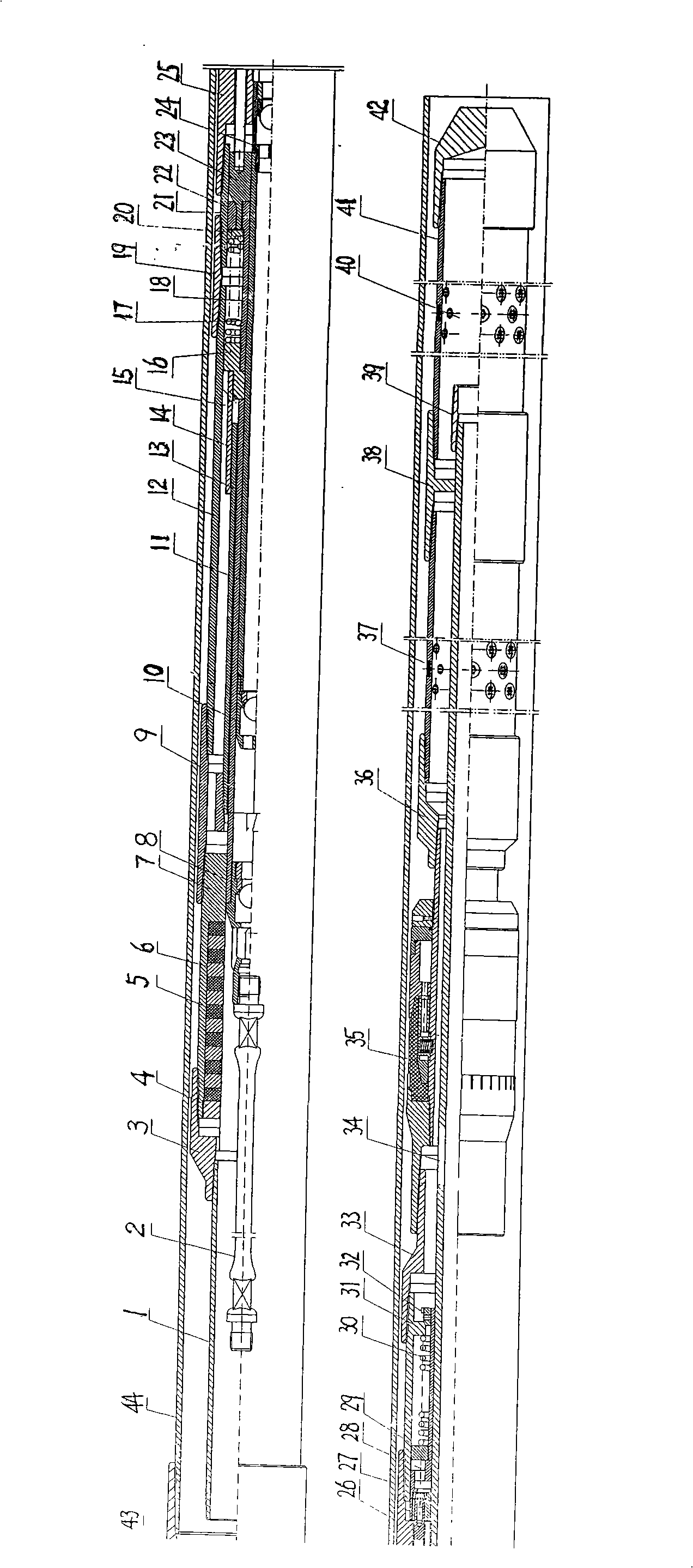

[0007] Below in conjunction with accompanying drawing, the implementation of the present utility model is described.

[0008] As shown in the figure, the present invention includes five parts: double long pump barrel, long plunger, valve group, steam injection device and sand control device, consisting of 3 1 / 2 "Oil pipe 1, sucker rod 2, variable buckle short connection 3, 33, 36, locking cap 4, pump barrel outer seal 5, ring gasket 6, upper sealing body 7, pump barrel valve assembly 8, 5 1 / 2 "Casing collar 9, valve assembly on plunger 10, plunger 11, 5 1 / 2 "Casing 12, pump barrel protection sleeve 13, pump barrel 14, sand discharge pipe 15, bump pump cap 16, upper spring 17, bump pump short-circuit 18, 5 1 / 2 "Coupling 19, upper spring seat 20, 5 1 / 2 "Short connection 21, sealing valve seat 22, upper sealing valve 23, plunger lower valve assembly 24, working cylinder 25, pull rod 26, lower sealing ring 27, connection seat 28, lower spring seat 29, lower spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com