Sump pump activation switch

a technology of pump activation switch and switch, which is applied in the direction of pump control, positive displacement liquid engine, non-positive displacement fluid engine, etc., can solve the problems of improper mounting of sensors, poor ground reference, and switch to malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

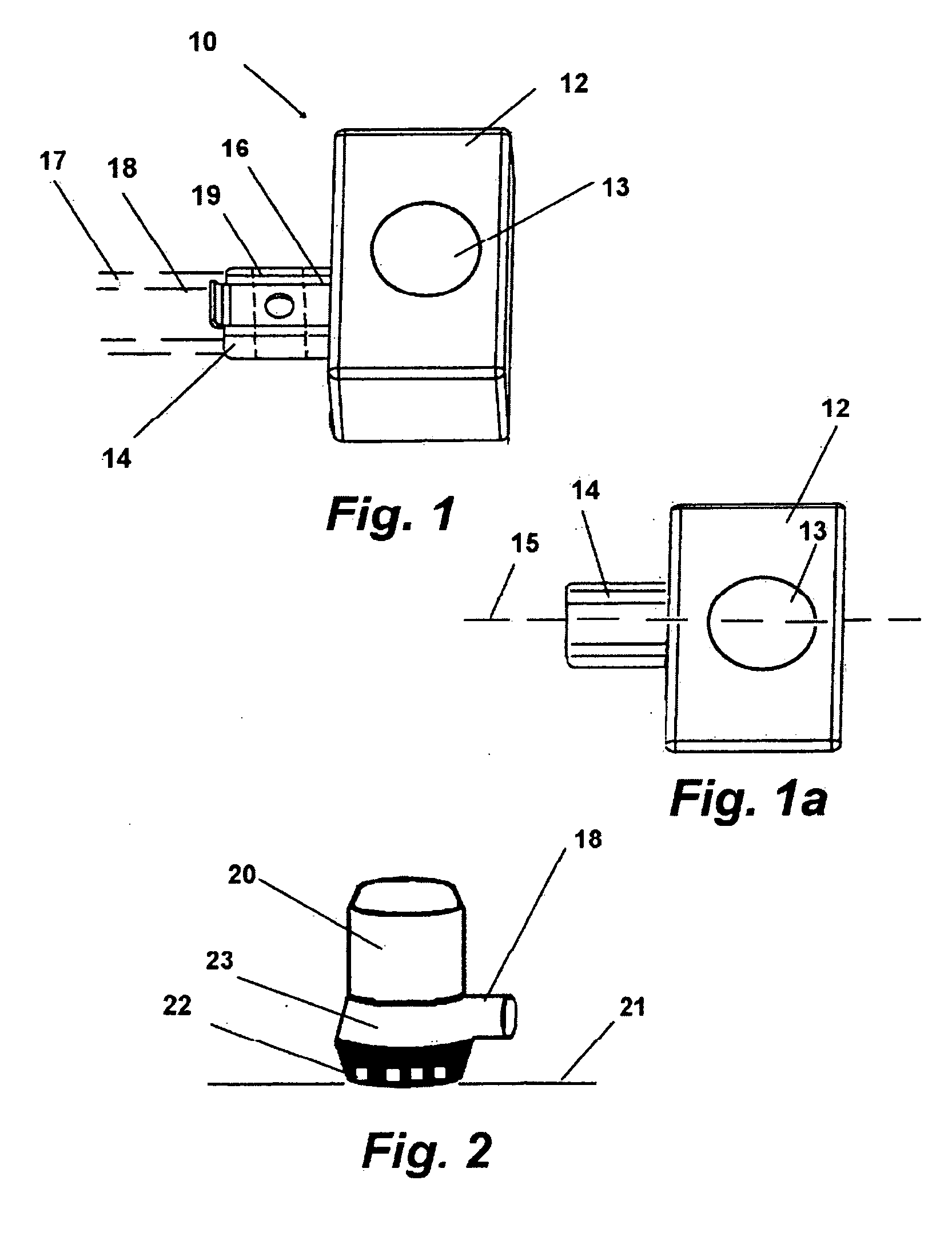

[0029]Referring now to the drawings in FIGS. 1-5, FIG. 1 shows a perspective view of the disclosed sump pump switch device 10 having a housing 12 having and extending grounded metal mounting member 14 which has a curve about its center axis or curved edge 16 portion. The electronic components for the impedance sensing device are engaged inside the housing 12 in a fashion that seals them from fluid in the tank. Wires (not shown) communicate to the circuit inside the housing 12 to provide electric energy to the circuit.

[0030]The mounting member 14 is connected inside the housing 12 to the ground wire or circuit providing electric power to the device 10 thereby providing the mounting member 14 a direct electrical link to the ground of the electrical system or battery. The curved shape of the mounting member 14 provides it with a means for cooperative surface engagement with the curved surface of a sump pump exhaust hose 17 which is engaged over a hose bib 18 and secured with a hose cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com