Thermal oil production pipe column for injection-production in the same well for vertical well and oil production method thereof

A technology of injection production and thermal oil production in the same well, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc., can solve the problems of increased lifting costs, waste of steam heat, and high operating costs, reducing operating time, Cost savings, reduced drilling and operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

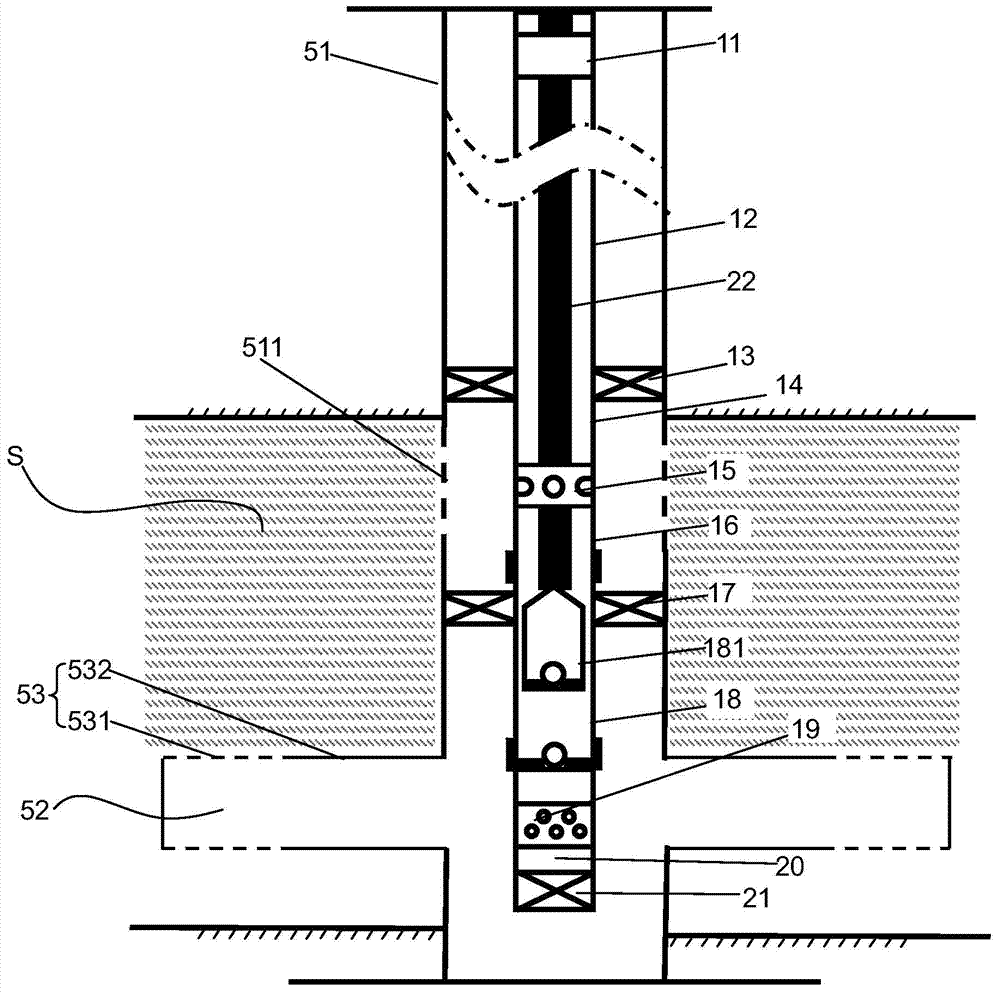

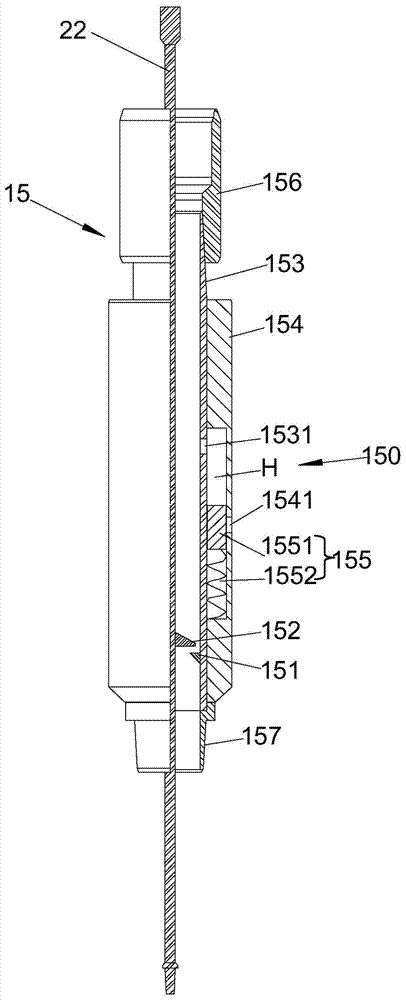

[0043]The present invention proposes a same-well injection-production thermal oil production string for vertical wells, which includes telescopic pipes connected sequentially from top to bottom, a first heat-insulating pipe, an upper packer, a second heat-insulating pipe, and a steam injection unit. Flow valve, tubing, lower packer, oil well pump, screen pipe, liner and plug, inside which there is a sucker rod, the lower end of the oil sucker rod is connected with the floating valve in the oil well pump ; Wherein, the side wall of the steam injection check valve is provided with a flow channel that can be unidirectionally conducted from the inside to the outside, and a fixed sealing ring plate and a The movable sealing ring plate placed on the fixed sealing ring plate, the movable sealing ring plate is sleeved on the sucker rod, and its outer peripheral edge is in sealing contact with the upper surface of the inner peripheral edge of the fixed sealing ring plate.

[0044] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com