Multi-parameter monitoring device of oil well and working method thereof

A monitoring device and multi-parameter technology, applied in surveying, earthmoving, wellbore/well components, etc., can solve the problem of not being able to timely and continuously reflect changes in oil well water content, affecting timely, correct evaluation, and testing errors of oilfield production wells Large (tens of meters to hundreds of meters, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

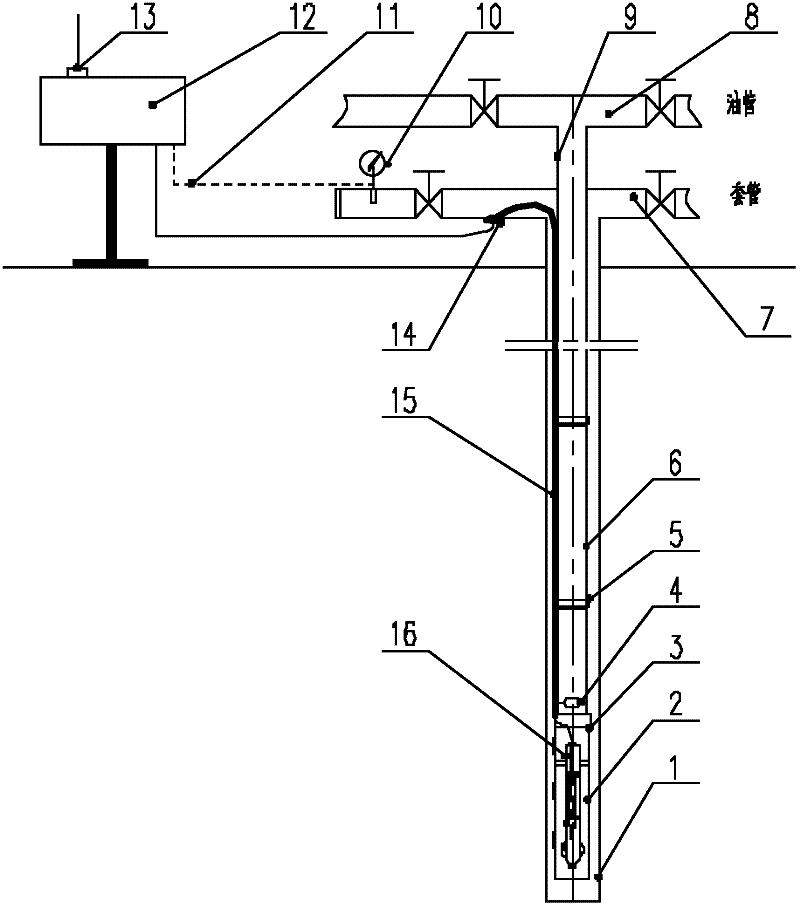

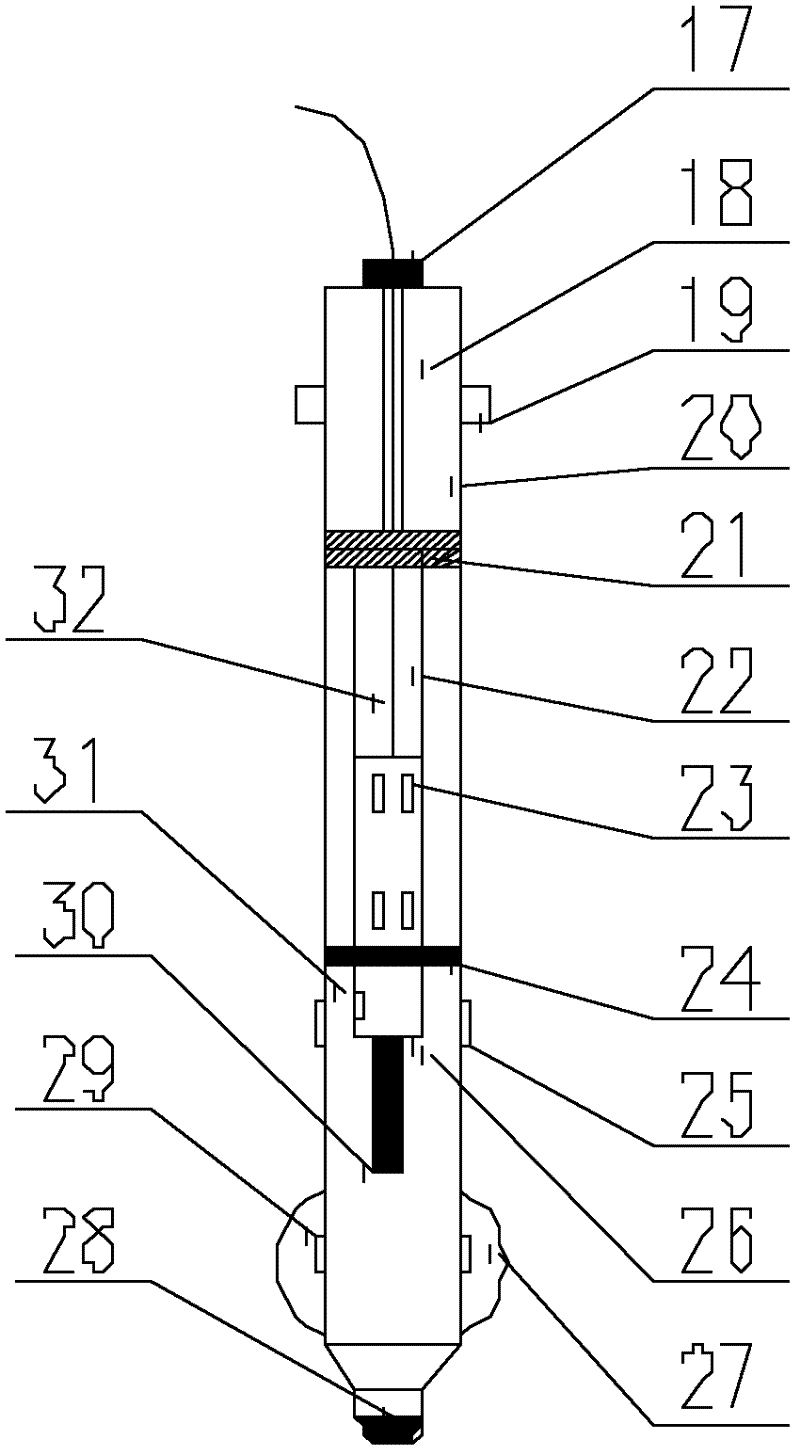

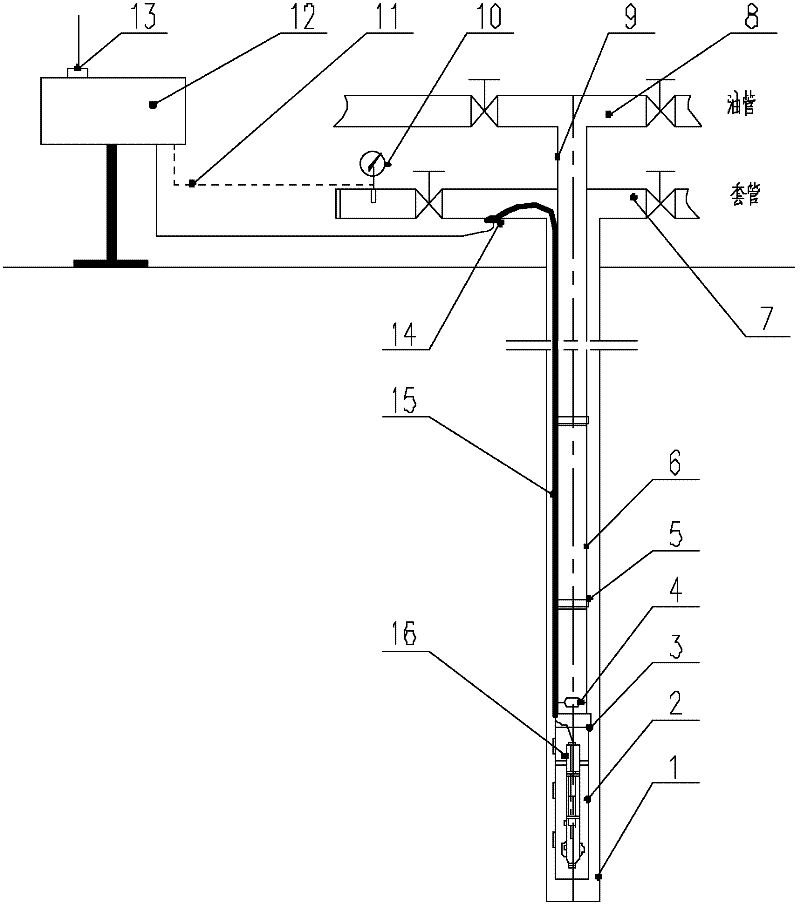

[0020] Such as figure 1 As shown, the oil well multi-parameter monitoring device in the embodiment of the present invention may include:

[0021] Casing 1, support cylinder 2, support cylinder collar 3, oil well pump 4, cable protector 5, tubing 6, casing manifold 7, tubing manifold 8, wellhead device 9, casing pressure test sensor 10, casing pressure signal Line 11, data acquisition device 12, wireless transmitter 13, wellhead cable sealing device 14, single-core logging cable 15, oil well multi-parameter tester 16;

[0022] The structural relationship of each part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com