Oil production pump

A technology for oil production pumps and oil well pumps, applied to pumps, pumps with flexible working elements, liquid displacement machinery, etc., can solve problems such as waste of energy, difficulty in stroke adjustment, complex structure, etc., and achieve energy saving and oil output cycle The effect of long life and small oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

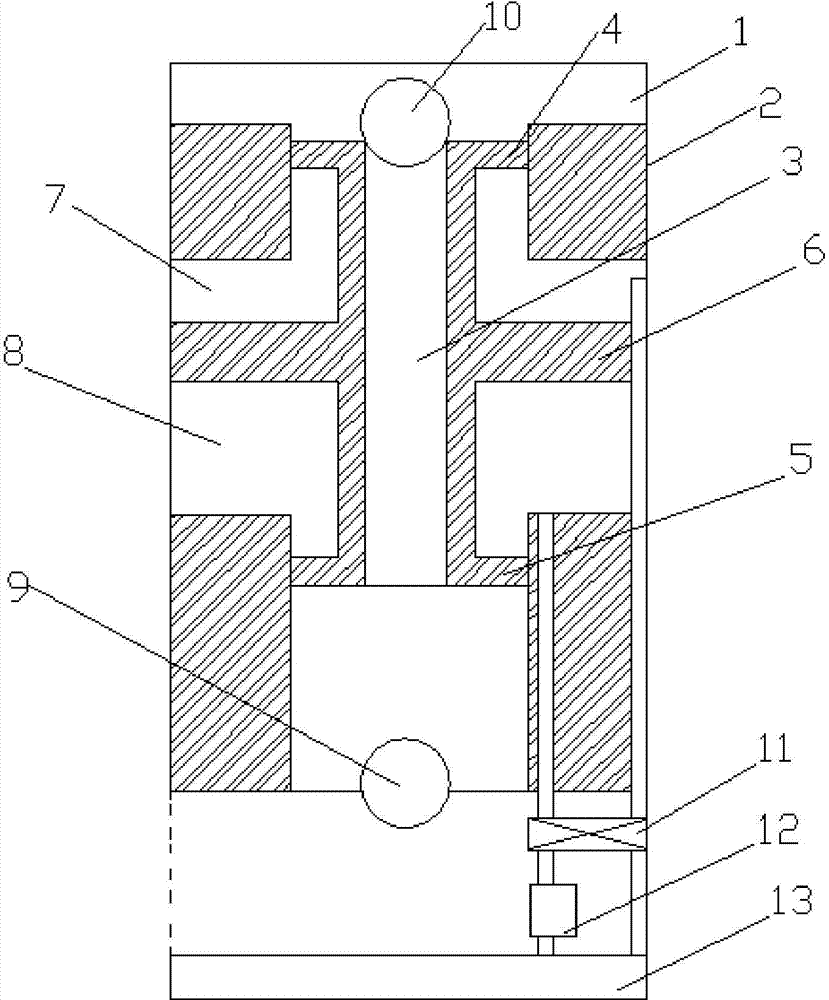

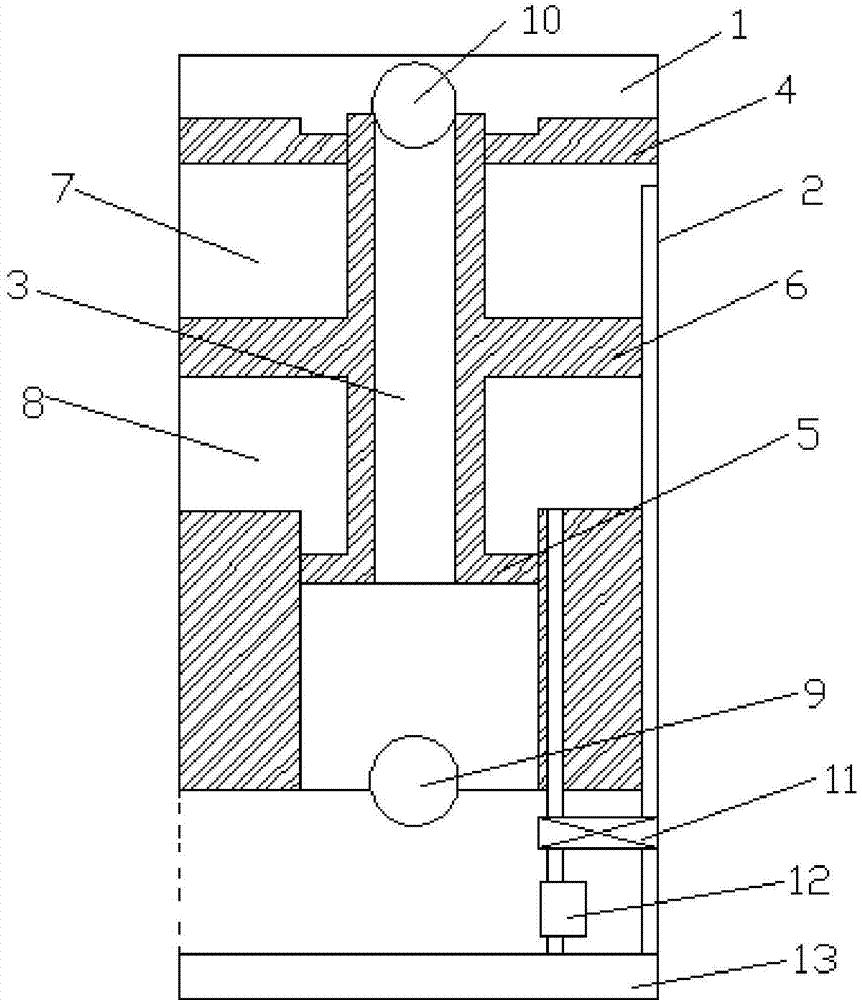

[0019] Such as figure 1 As shown, an oil production pump includes an oil well pump 1 and a hydraulic system. The hydraulic system is arranged at the lower end of the oil well pump 1. The key point is that the oil well pump 1 includes a pump body 2, which is cylindrical. The cross-sectional area of the cavities at both ends is smaller than the cross-sectional area of the cavity in the middle of the pump body 2. The lower end of the pump body 2 is a closed surface, and a square hole or a round hole is arranged on the closed surface. An oil inlet valve 9 is arranged on the top, and the oil inlet valve 9 is a one-way valve; an oil suction pipe 3 is arranged at the axial middle position inside the pump body 2, and the oil suction pipe 3 is also cylindrical, and its length is shorter than that of the pump body. 2, the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com