Pumpjack dynamometer and method

a dynamometer and push rod technology, applied in the field of push rod dynamometers, can solve the problems of not always providing accurate or reliable information, adversely affecting the reliability of much of the sensing equipment, and being subject to wear and tear, etc., and achieve the effect of long-term calibration errors and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

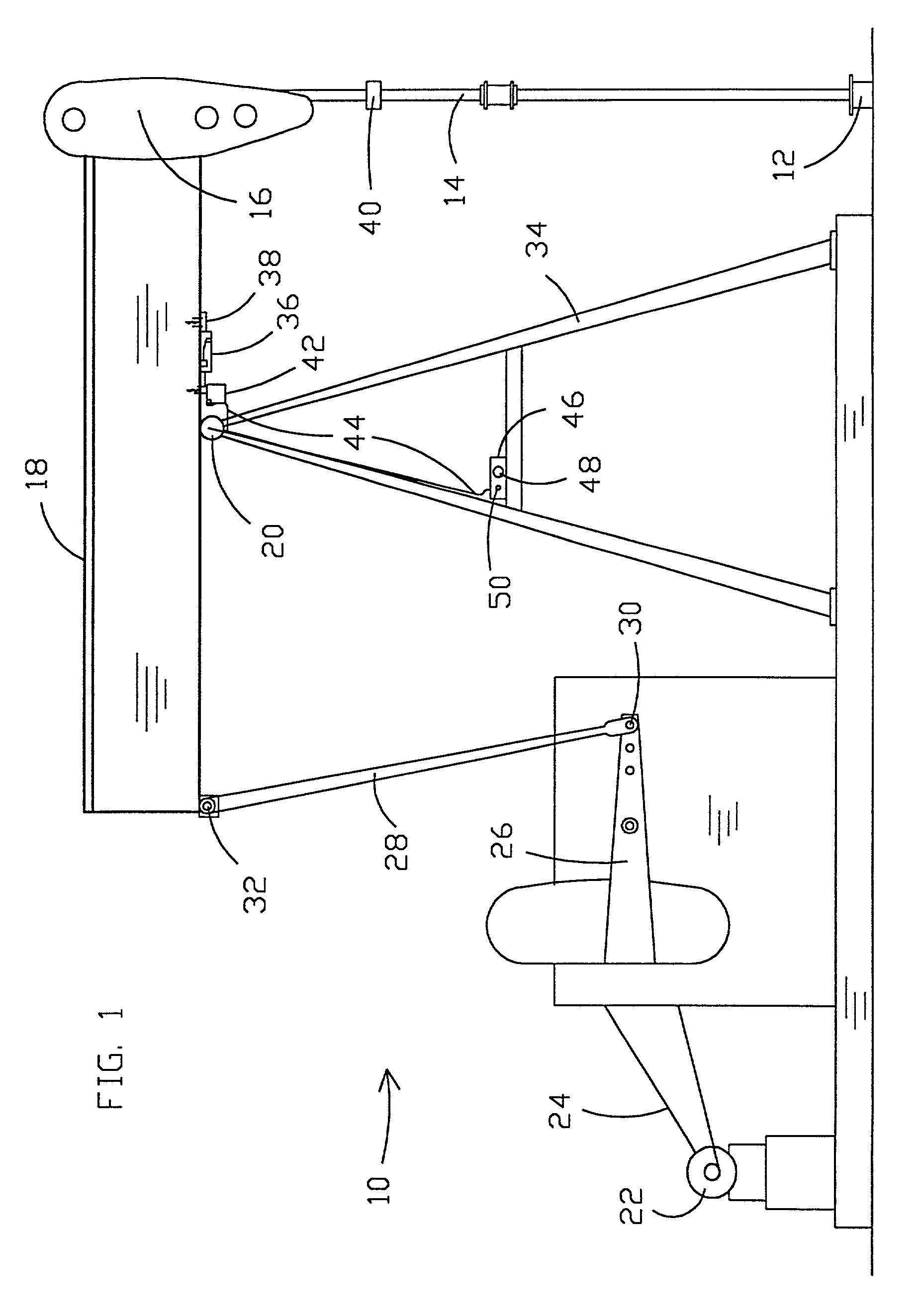

[0060] Referring now to the drawings, and more particularly to FIG. 1, a pumpjack unit 10 is shown in operative relationship respective to a wellhead 12. A downhole pump (not shown) is activated by reciprocal movement of sucker rod string (not shown) and polished rod 14 that is suspended from horse head 16. Horse head 16 is affixed to walking beam 18, which is a rigid beam that extends on either side of pivot connection 20. Walking beam 18 is reciprocated by a prime mover 22, which may typically comprise an electric motor. Prime mover 22 drives walking beam 18 through a drive system which may typically comprise elements such as drive belt 24, crank arm 26, drive arm 28 that is pivotally connected to walking beam 18 and crank arm 26 with pin connections 30 and 32. Walking beam 18 is pivotally supported by a suitable frame 34 such that walking beam pivots in two different directions, moving sucker rod string and polished rod 14 upwardly and downwardly during each pump stroke.

[0061] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com