Method for underbalanced tubing descending, non-well-killing gas lifting, rotary pumping, pump maintaining and tubing maintaining

An underbalanced tubing technology, applied in the fields of snubbing gas lift, underbalanced tubing, pumping, pump inspection and tubing maintenance, which can solve the problems of weakening reservoir protection effect, blocked production channels, and increased operation cycle , to achieve the effect of maintaining production capacity improvement, simplifying production operations, and reducing oil production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

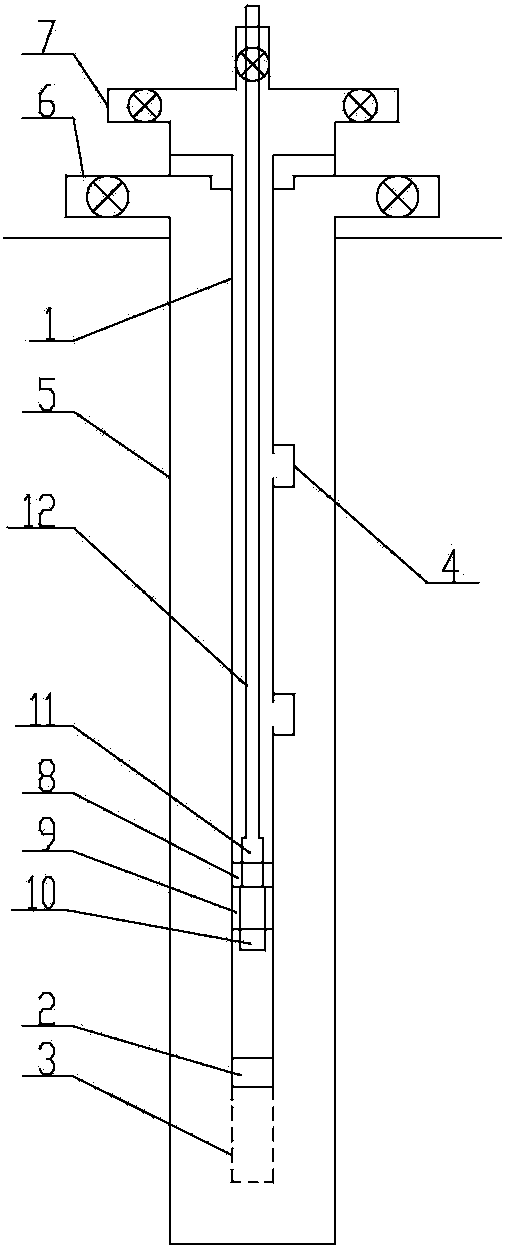

[0018] Embodiment 1: The under-balanced oil tubing, snubbing gas lift, transfer pumping, pump inspection and tubing maintenance methods are carried out as follows: first step, the bottom end of the tubing string 1 is fixed sequentially from top to bottom Install the blowout preventer 2 in the oil pipe and the basket 3, install the float valve in the blowout preventer 2 in the oil pipe, fix the movable device in the blowout preventer 2 in the oil pipe, and install not less than one in the middle of the oil pipe string 1 Forward gas lift valve 4, fixedly install pump seat 8 in tubing string 1, fixedly install pump sealing device 9 on the inner side of the lower part of pump seat 8, and fixedly install pump sealing valve on pump sealing device 9, close the upper end of casing 5 Fixed on the wellhead, the oil production spool 6 is fixedly installed on the casing 5 above the wellhead; in the second step, the tubing string 1 is lowered into the casing 5, and then the upper end seat ...

Embodiment 2

[0019] Embodiment 2: The difference from the above embodiment is that after the eighth step is completed, the following steps are followed in sequence: the ninth step is to lower the tubing string 1 into the casing 5, and then put the upper end of the tubing string 1 The seat is hung in the oil production spool 6, and finally the seat of the Christmas tree 7 is sealed on the oil production spool 6, wherein: during the running process, the pressure between the casing 5 and the tubing string 1 is controlled by rotating the blowout preventer; the tenth The first step is to put a special core pipe into the tubing string 1, lower the special core pipe to the blowout preventer 2 in the tubing, and push the movable device downwards by the special core pipe so that the inside of the blowout preventer and the tubing string 1 communicate with the well. Establish the production channel; in the eleventh step, the oil well pump 11 is fixedly installed on the lower end of the oil well pump...

Embodiment 3

[0020] Embodiment 3: As an optimization of the above-mentioned embodiment, the blowout prevention device 2 in the oil pipe is a pipe-poke type oil pipe float valve, and a float valve valve is installed in the pipe-poke type oil pipe float valve, and the movable device is a float valve valve. In the ninth step During the running of the tubing string 1 into the casing 5, the positive circulation operation is performed on the tubing string 1 running into different well sections. When the positive circulation operation starts each time, the float valve valve and seal on the tubular tubing float valve The sealing pump valves on the pump 9 are automatically opened, and after the positive cycle operation is completed, the sealing pump valves and the valves are automatically closed; in the tenth step, a special core tube is put into the tubing string 1, and the special core tube pushes the float valve valve open , the float valve valve is in an open state, so that the tubing string 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com