Combined method of underbalanced well completion downhole tubing and gas lift commissioning

An underbalanced, tubing technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve the problem of underbalanced drilling with weakened reservoir protection effect, uplift of operation cycle, gas lift drainage or blocked production channels and other problems, to achieve the effect of maintaining the effect of productivity improvement, shortening the operation cycle, and strengthening the effect of reservoir protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

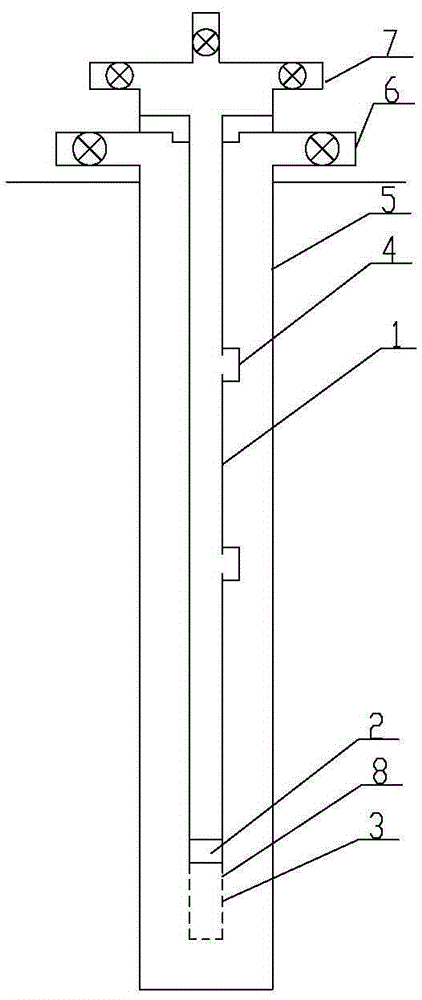

[0018] Embodiment 1: The method of the underbalanced completion downhole tubing and gas lift combined production is carried out according to the following method: the first step, the bottom end of the tubing string 1 is fixed and installed in sequence from top to bottom. The blowout preventer 2 and Lifting basket 3, fixedly install the valve fixing seat in the blowout preventer 2 in the oil pipe, install the valve in the valve fixing seat, and install no less than one reverse gas lift valve 4 in the middle of the oil pipe string 1. The upper end is fixed on the wellhead, and the oil production spool 6 is fixedly installed on the casing 5 above the wellhead, wherein: the starting pressure of the reverse gas lift valve 4 is set to be greater than the liquid column pressure of the predetermined well section; the second step, Run the tubing string 1 into the casing 5, then hang the upper end seat of the tubing string 1 in the oil production spool 6, and finally seal the Christmas...

Embodiment 2

[0019] Embodiment 2: As an optimization of the above embodiment, the blowout preventer 2 in the oil pipe is a valve type oil pipe float valve device, the valve fixing seat is a valve valve seat, and the valve is installed in the valve valve seat through a torsion spring. In the third step, Throw the rod into the oil pipe through the Christmas tree 7, and the rod pushes down the valve seat in the valve type oil pipe float valve device. The tubing string 1 communicates with the inside of the well, so that the tubing string 1 communicates with the inside of the well to establish a production channel. The valve type oil pipe float valve device adopts the technology in the Chinese patent document with the publication number CN202500534U.

Embodiment 3

[0020] Embodiment 3: As an optimization of the above-mentioned embodiment, the blowout preventer 2 in the oil pipe is a fixed pressure floating valve of the oil pipe with a ball-throwing pressure and open type, the valve fixed seat is a valve core, and the valve is installed on the valve core. The pressure ball is put into the constant pressure float valve of the oil pipe constant pressure float valve of the ball-casting and pressure-holding type. Hold the pressure, send the spool of the constant pressure float valve and the valve on the spool to the lift basket 3 together, and connect the tubing string 1 with the well through the through hole 8 on the lift basket 3 to establish a production channel. The constant pressure float valve of the oil pipe with the ball-throwing pressure and open type adopts the technology in the Chinese patent document with the publication number of CN102606108A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com