Offshore oilfield anti-emulsification workover fluid as well as preparation method and use method thereof

An offshore oil field, anti-emulsification technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as impact, limited processing capacity of surface oil-water separation devices, and affect normal production of offshore platforms, etc., to achieve enhanced flowback performance , Improve production capacity recovery effect, solve the effect of demulsification and dehydration difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

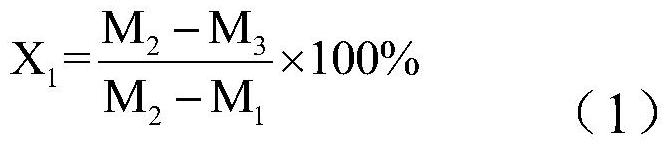

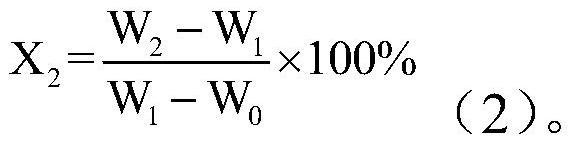

[0032] The present invention also proposes a method for preparing an anti-emulsification workover fluid in an offshore oilfield, which comprises the following steps: 1) water is obtained through pretreatment of production sewage and / or water source well water; the water conforms to the requirements of "Q / HS2042-2014 2) Add the water into the constant temperature stirring tank for heating, so that the temperature of the water is greater than 50 °C; 3) In terms of mass percentage, add 0.5-1.5 % of the drainage aid cleaning agent and 0.1-0.5% of the demulsifier, and stirred evenly to obtain the anti-emulsification workover fluid in the offshore oil field, the total amount of which is 100%.

[0033] The present invention also proposes a method for using the anti-emulsification workover fluid in the offshore oil field to control the temperature of entering the well of the anti-emulsification workover fluid in the offshore oil field to >50°C. By controlling the temperature of the wo...

Embodiment 1

[0062] Add water to the constant temperature stirring tank and heat it to make the water temperature > 50°C; add 1.5% of drainage aid cleaning agent and 0.4% of demulsifier to it, and stir evenly, the total amount is 100%. Wherein, the drainage aid cleaning agent is a mixed aqueous solution comprising sodium dodecylbenzene sulfonate, octadecyl hydroxypropyl sulfobetaine, sodium lignosulfonate and glycerol, wherein the dodecyl The effective content of sodium benzene sulfonate ≥ 15%, the effective content of octadecyl hydroxypropyl sulfobetaine ≥ 15%, the effective content of sodium lignosulfonate ≥ 10%, the effective content of glycerol ≥ 10% . The demulsifier is an aqueous solution of bisphenol A phenolic resin-based polyether, the effective content of which is greater than or equal to 30%.

[0063] The performance evaluation results of the workover fluid of this embodiment are shown in Tables 1 to 4 below.

Embodiment 2

[0065] The same as in Example 1, the proportions of the raw materials are as follows: 1.0% of a cleaning aid for drainage and 0.5% of a demulsifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com