Method and device for judging optimal times of stroke of pumping unit

A technology of optimal stroke times and determination methods, which is applied to earth-moving drilling, production of fluids, wellbore/well components, etc. It can solve problems such as large computational load, limited chip performance, and inability to run programs, and achieve reliable system operation, The effect of simplifying the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

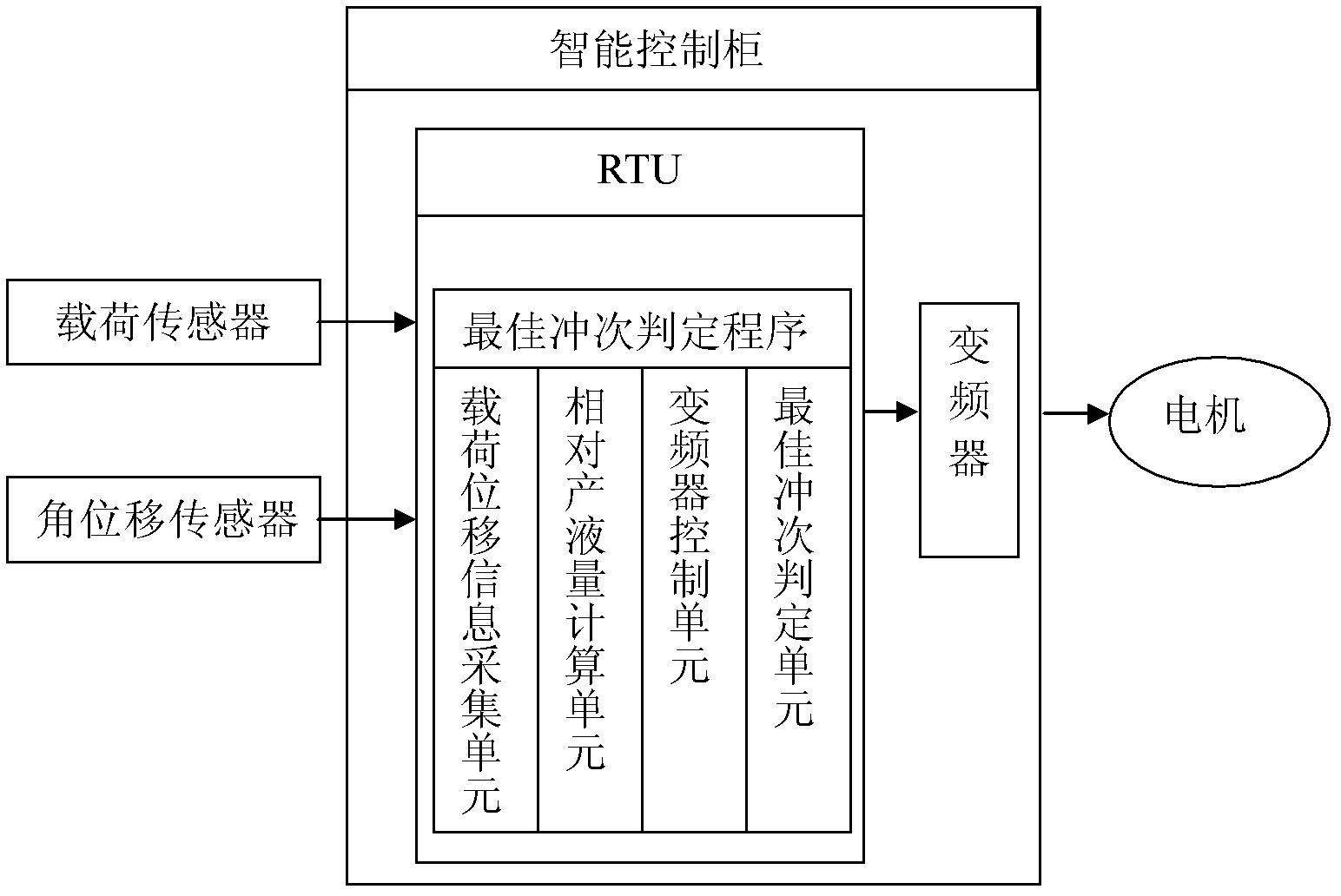

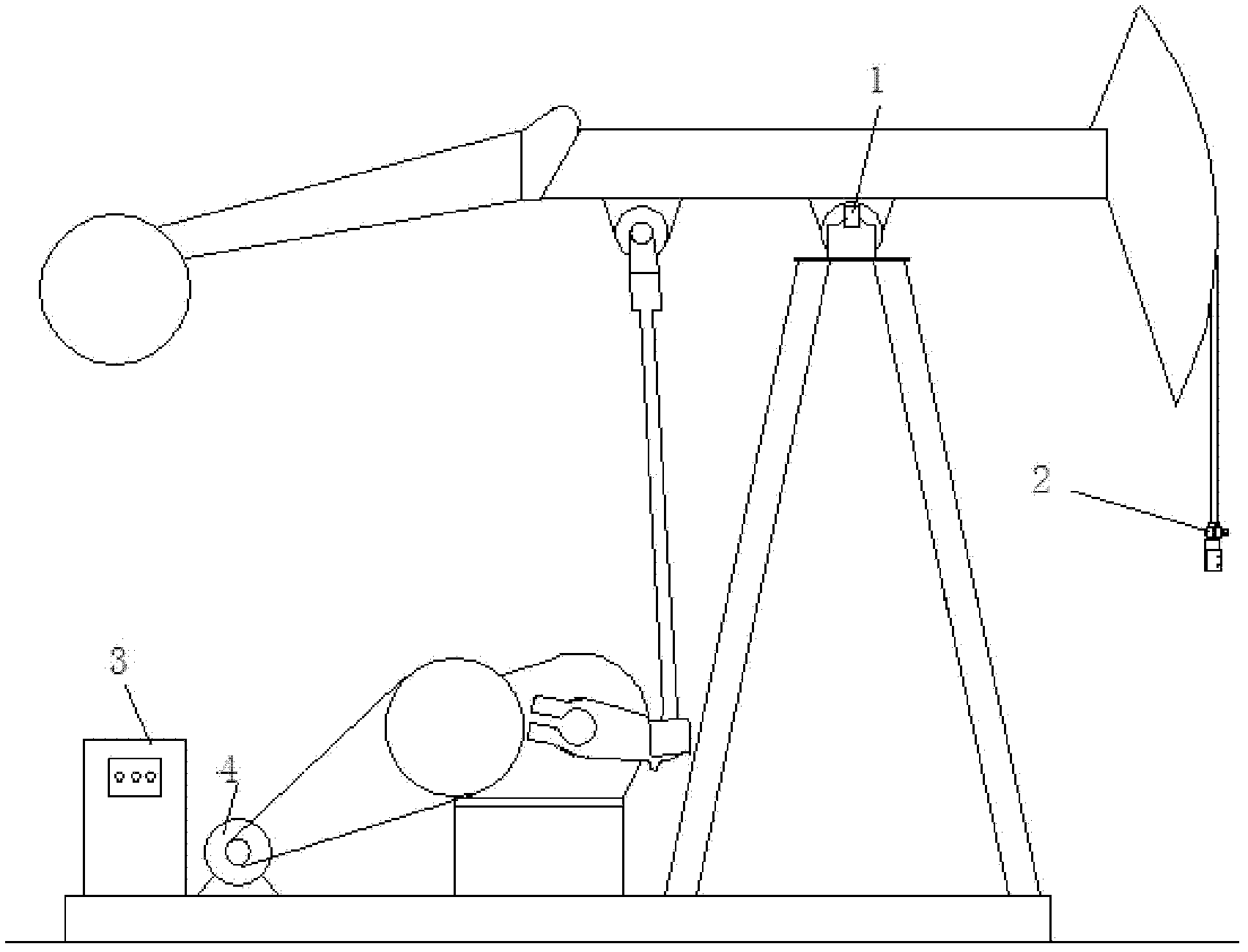

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

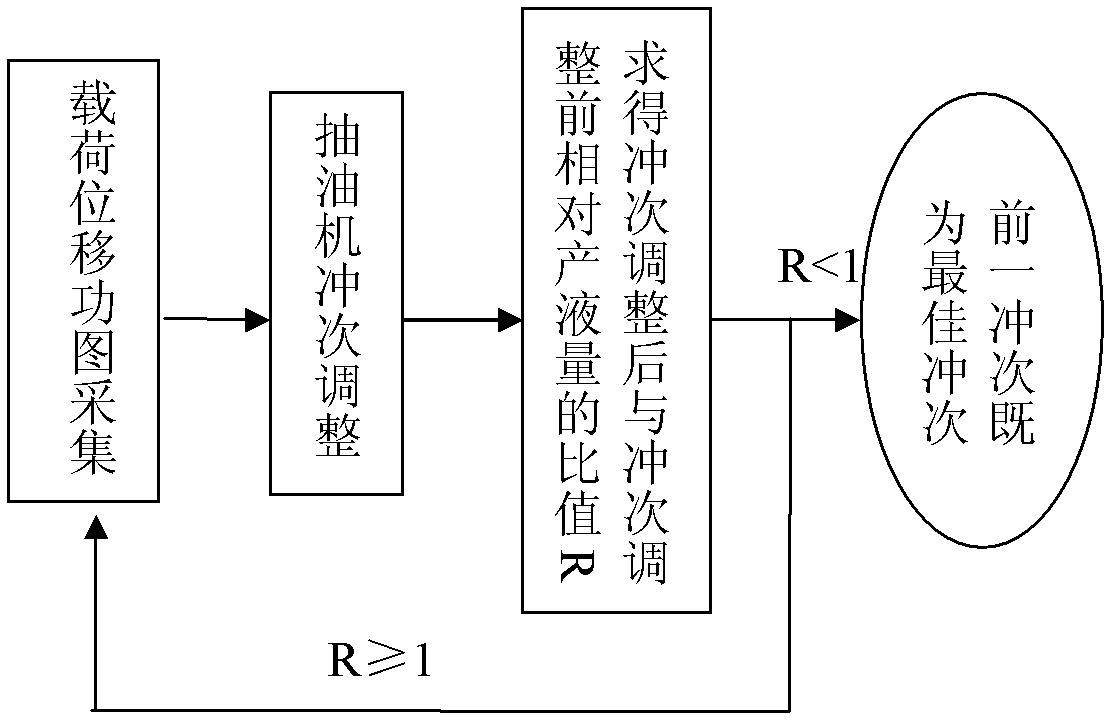

[0041] A method for judging the optimal number of strokes of a pumping unit, the flow of the judging procedure is as follows figure 1 Shown:

[0042] Step 1, obtain the load-displacement work diagram of the pumping unit under the current stroke, and obtain the relative liquid production volume of the pumping unit under the current stroke through calculation;

[0043] Step 2: Change the stroke frequency of the pumping unit, reacquire the load-displacement work diagram after the stroke frequency change, and obtain the relative fluid production after the stroke frequency change;

[0044] Step 3, obtaining the ratio R of the relative liquid production volume under the next stroke in step 2 and the relative liquid production volume under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com