A kind of submicron composite ball and its preparation method and its application as silicone rubber porcelain filler

A composite ball and sub-micron technology, which is applied in the treatment of fibrous fillers and dyed organic silicon compounds, can solve the problem of affecting the molding process and comprehensive performance of silicone rubber/filler composite materials, the large amount of inorganic filler added, and the consumption of modifiers. Large and other problems, to achieve the effect of being convenient for mass production, easy to form and process, and good self-supporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 (preparation of solid submicron composite ball filler)

[0062] The raw materials are 3-methacryloyloxypropyltrimethoxysilane and lithium diatomaceous earth, and the initiator is potassium persulfate. Add 0.5mL of 3-methacryloyloxypropyltrimethoxysilane and 0.1g of lithium diatomaceous earth into 40mL of water, stir at 30°C for 6 hours, then raise the temperature to 70°C, add 10mg of potassium persulfate to initiate polymerization, and the polymerization reaction lasts for 12 hours. The resulting emulsion is centrifuged, washed with ethanol three times, dispersed in water, and freeze-dried to obtain a white powder solid filler.

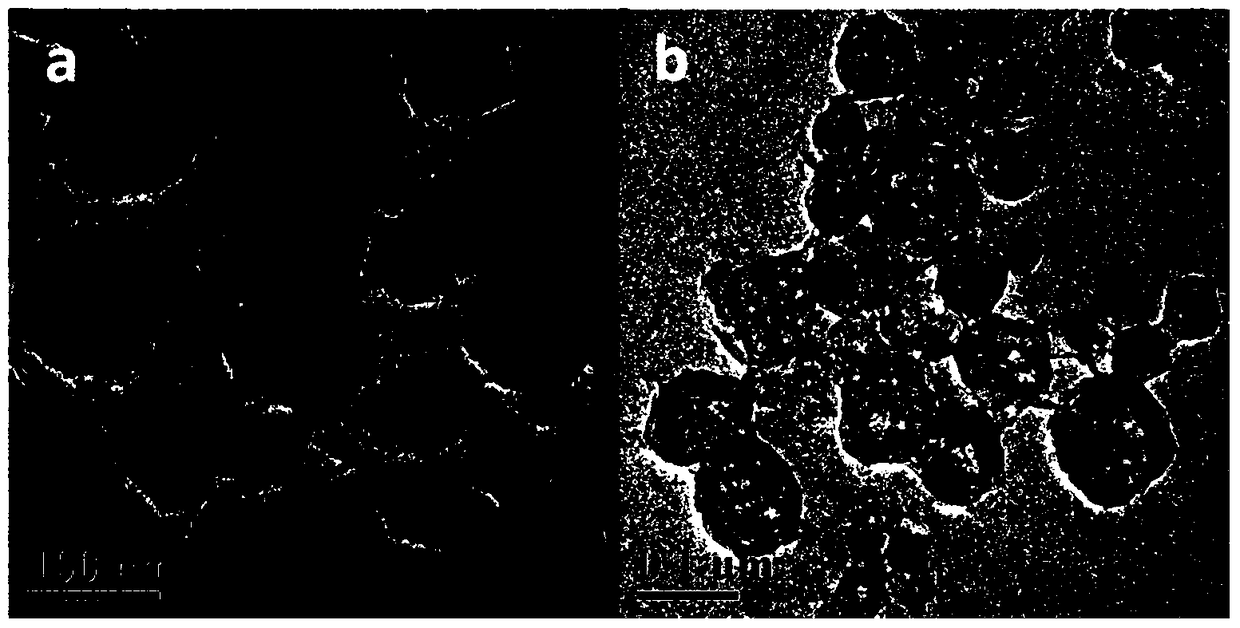

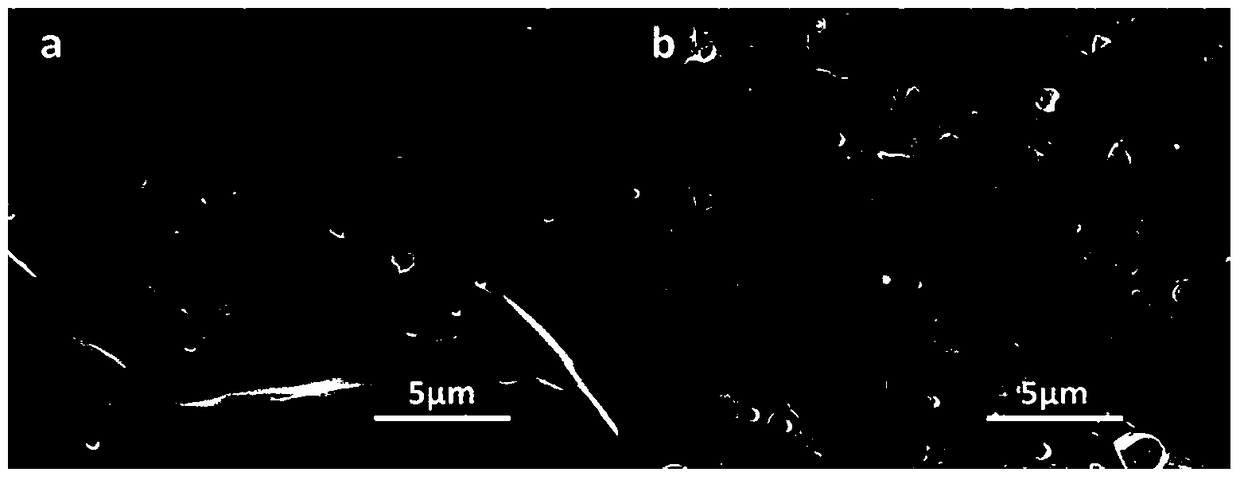

[0063] The above powder was dispersed in ethanol to make a transmission electron microscope sample, and the filler morphology was observed. Such as figure 1 as shown in a.

[0064] Depend on figure 1 a It can be seen that the solid submicron composite spheres prepared in this example have a hydrophobic polymer part and a hydrop...

Embodiment 2

[0065] Embodiment 2 (preparation of hollow submicron composite ball filler)

[0066] The raw materials are 3-methacryloyloxypropyltrimethoxysilane, lithium diatomaceous earth and isopropyl acetate, and the initiator is potassium persulfate. Add 1mL of 3-methacryloyloxypropyltrimethoxysilane, 0.3g of lithium diatomaceous earth, and 1mL of isopropyl acetate into 60mL of water, stir at 10°C for 28 hours, then raise the temperature to 70°C, add 20mg of potassium persulfate to initiate polymerization, and polymerize The reaction lasted 18 hours. The resulting emulsion was centrifuged, washed with ethanol three times, dispersed in water, and freeze-dried to obtain a white powder solid filler.

[0067] The above powder was dispersed in ethanol to make a transmission electron microscope sample, and the filler morphology was observed. Such as figure 1 as shown in b.

[0068] Depend on figure 1 b It can be seen that the hollow submicron composite spheres prepared in this example ha...

Embodiment 3

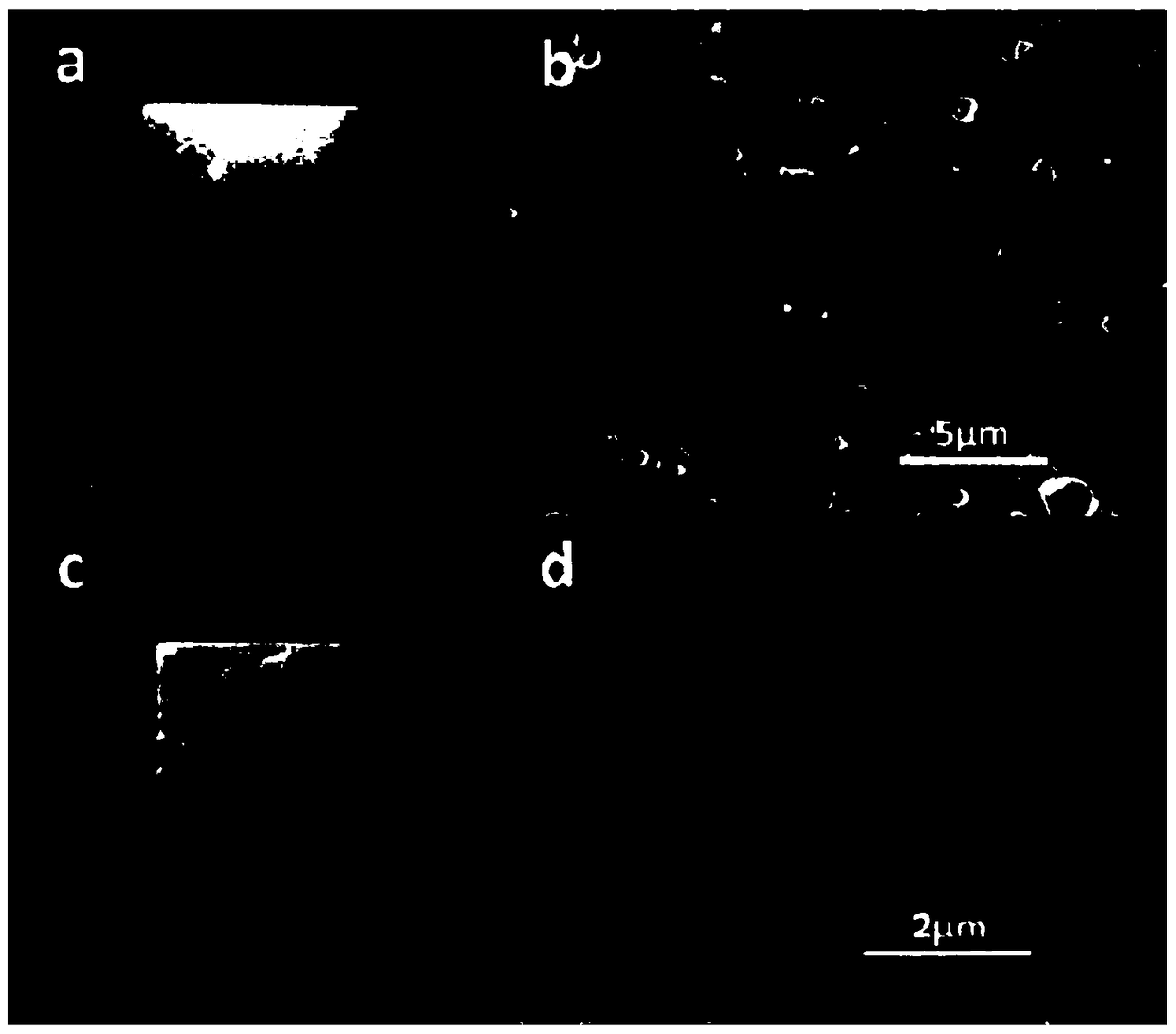

[0069] Embodiment 3 (preparation of solid submicron composite ball filler)

[0070] The raw materials are 3-methacryloyloxypropyltrimethoxysilane and lithium diatomaceous earth, and the initiator is azobisisobutylamidine. Add 1mL of 3-methacryloyloxypropyltrimethoxysilane and 0.3g of lithium diatomaceous earth into 150mL of water, stir at 20°C for 24 hours, then raise the temperature to 65°C, add 15mg of azobisisobutylamidine to initiate polymerization, and the polymerization reaction continues 18 hours. The resulting emulsion is centrifuged, washed with ethanol three times, dispersed in water, and freeze-dried to obtain a white powder solid filler.

[0071] The solid submicron composite sphere prepared in this embodiment has a hydrophobic polymer part and a hydrophilic lethionite sheet, and the lethionite sheet is coated on the surface of the polymer to form an armor structure, which is an organic-inorganic composite structure. The particle size of the submicron composite b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com