Corrosion resistant and squeezing highly resistant oil casing pipe and preparation method thereof

A technology for oil casing and corrosion resistance, applied in the field of oil casing, can solve the problem that the oil casing can not meet the requirements of corrosion resistance and anti-collapse performance at the same time, and achieves the improvement of stress corrosion cracking resistance, corrosion resistance, corrosion resistance, etc. Conducive to the control of ovality and wall thickness unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

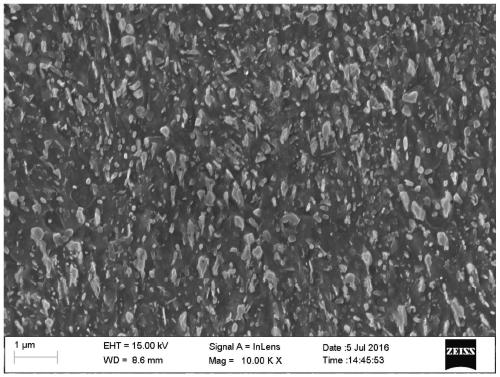

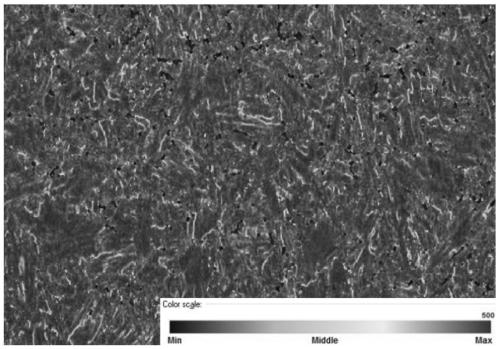

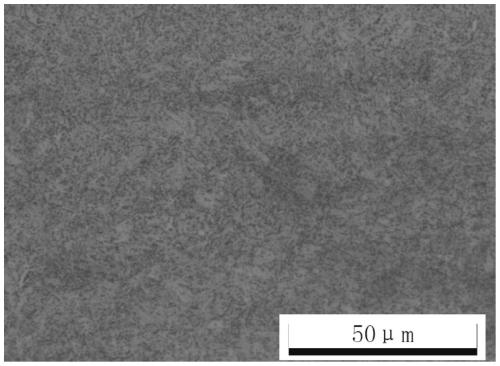

Image

Examples

Embodiment 1

[0046] The embodiment of the present invention provides a corrosion-resistant and high-collapse-resistant petroleum casing:

[0047] Using scrap steel as raw material, through 80t electric arc furnace smelting→LF refining→VD vacuum refining→continuous casting→slab slow cooling to make continuous casting round billet, the weight percentage of its chemical composition is: C 0.22%, Si 0.35%, Mn 0.45 %, S 0.003%, P0.008%, Al 0.04%, Cr 0.75%, Mo 0.55%, Ca0.002%, N0.006%, and the rest are Fe and unavoidable impurities.

[0048] The obtained continuous casting round billet is heated in an annular furnace, pierced, rolled by a precision cross-rolling unit, reduced in micro tension, quenched and tempered, and straightened at a high temperature to make an outer diameter of 139.7mm and a wall thickness of 9.17mm; Casing with a yield strength of 95KSI.

[0049] In the heating process of the ring furnace, the temperature of the heating section is 1240°C, the temperature of the soaking sec...

Embodiment 2

[0058] The embodiment of the present invention provides a corrosion-resistant and high-collapse-resistant petroleum casing:

[0059] Using scrap steel as raw material, through 80t electric arc furnace smelting→LF refining→VD vacuum refining→continuous casting→slab slow cooling to make continuous casting round billet, the weight percentage of its chemical composition is: C 0.25%, Si 0.20%, Mn 0.40 %, S 0.002%, P0.01%, Al 0.03%, Cr 1.10%, Mo 0.55%, Ca0.0025%, N 0.08%, and the rest are Fe and unavoidable impurities.

[0060] The obtained continuous casting round billet is heated in an annular furnace, pierced, rolled by a precision cross-rolling unit, reduced in micro tension, quenched and tempered, and straightened at high temperature to make an outer diameter of 177.8mm and a wall thickness of 10.36mm; Casing with a yield strength of 110KSI.

[0061] In the heating process of the ring furnace, the temperature of the heating section is 1260°C, the temperature of the soaking sec...

Embodiment 3

[0070] The embodiment of the present invention provides a corrosion-resistant and high-collapse-resistant petroleum casing:

[0071] Using scrap steel as raw material, through 80t electric arc furnace smelting→LF refining→VD vacuum refining→continuous casting→slab slow cooling to make continuous casting round billet, the weight percentage of its chemical composition is: C 0.30%, Si 0.15%, Mn 0.60 %, S 0.001%, P0.006%, Cr 1.20%, Mo 0.25%, Ca 0.0018%, N 0.08%, and the rest are Fe and unavoidable impurities.

[0072] The obtained continuous casting round billet is heated in an annular furnace, pierced, rolled by a precision cross-rolling unit, reduced in micro tension, quenched + high temperature tempering heat treatment, and straightened at a high temperature, and made into an outer diameter of 219.1mm and a wall thickness of 12.7mm; casing with a nominal yield strength of 95KSI.

[0073] In the heating process of the ring furnace, the temperature of the heating section is 1280...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com