Patents

Literature

32results about How to "Improved resistance to stress corrosion cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistant and squeezing highly resistant oil casing pipe and preparation method thereof

The invention discloses a corrosion resistant and squeezing highly resistant oil casing pipe and a preparation method thereof. The oil casing pipe comprises, by weight percentage, 0.22%<=C<=0.30%, 0.15%<=Si<=0.35%, 0.40%<=Mn<=0.60%, S<=0.003%, P<=0.01%, 0.02%<=Al<=0.04%, 0.75%<=Cr<=1.20%, 0.25%<=Mo<=0.55%, Ca<=0.0025%, N<=0.08% and the balanced Fe and unavoidable impurities. The oil casing has theadvantages that the squeezing resistant strength of the prepared oil casing pipe is 30% or above higher than the squeezing resistant strength required by API 5C3 standards, the hydrogen sulfide corrosion resistance performance is conformed to demands in API 5CT (45 edition) PSL3, and the oil casing pipe can be extensively applied to the exploitation of oil and gas wells of acid medium deep wells, ultra-deep wells and the like with complicated geological conditions

Owner:DALIPAL PIPE

Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material

InactiveCN103131982AImprove wettabilityImprove bindingHot-dipping/immersion processesInterfacial reactionCerium

The invention discloses a multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material. The alloy comprises the following components: by weight, smaller than or equal to 15% of zinc (Zn), 0.5%-2.5% of silicon (Si), 3% of alloy enhancer copper (Cu), 0.5% of polarization alterant gold (Au), 0.5% of solvent passivator chrome (Cr), 0.3% of sediment hardening agent cadmium (Cd), 0.5% of grain refiner titanium (Ti), 0.5% of rare earth addition cerium (Ce), 1% of matrix interfacial reaction buffering agent, with the balance being aluminum (Al) and inevitable trace impurities. The Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material effectively solves the problem that the proportion of the hot-dip galvanizing occupying the zinc is high, and the zinc resource is saved. A great quantity of the aluminum is added to replace the zinc in the aluminum alloy coating material for hot dipping, due to the fact that the aluminum resource is rich and the cost is low, the comprehensive cost of the coating material is reduced.

Owner:GUIZHOU ACAD OF SCI

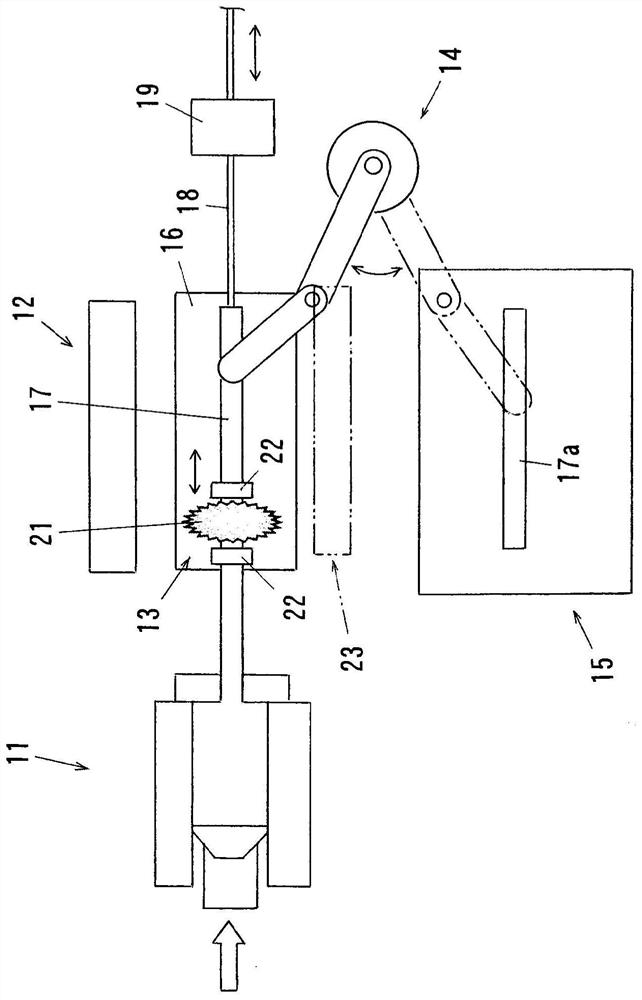

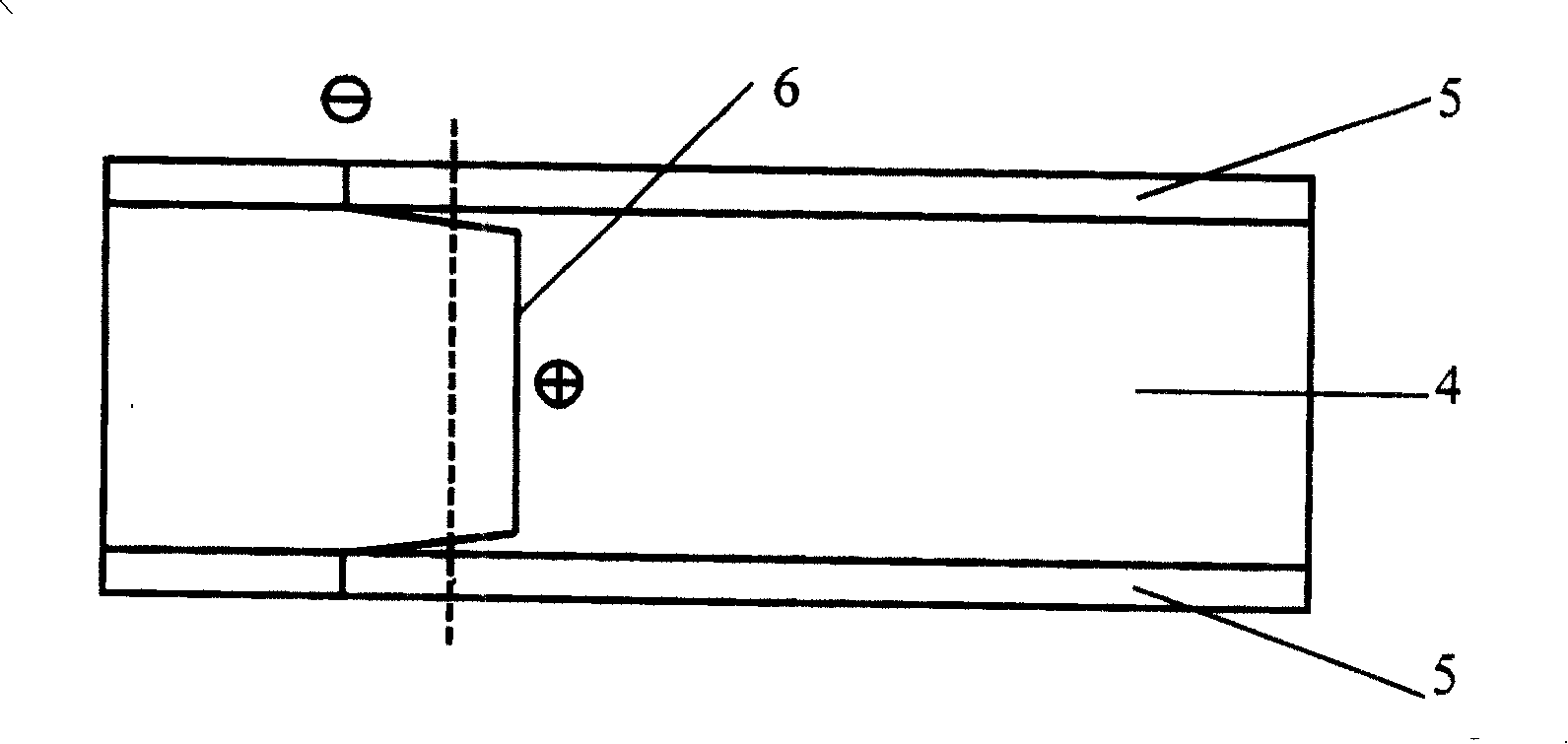

Method and system for manufacturing aluminum alloy part

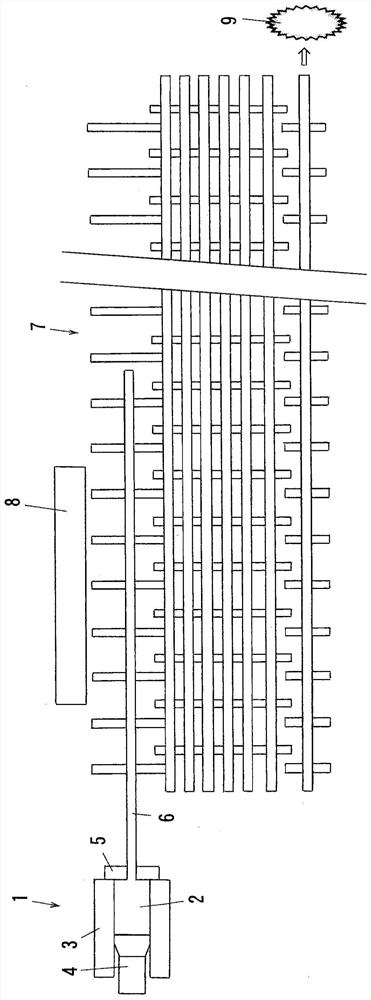

The invention provides a method for manufacturing an aluminum alloy part. When an aluminum alloy part is manufactured by subjecting a heat-treated aluminum alloy extruded material to plastic working,the method prevents the occurrence of cracks during plastic working at a lower cost than methods involving solution treatment or retrogression treatment. A manufacturing apparatus includes an extruderdevice (11) that performs hot extrusion processing on a heat-treated aluminum alloy; a cutting device (13) that is disposed on the output side of the extruder device (11), cuts the extruded material(17) to a predetermined length, and cuts the extruded material away from the extruder device (11); and a conveyance device (14) and a plastic working device (15) which are provided in the extruder device (11). The conveyance device (14) conveys the extruded material (17a) cut into a predetermined length by the cutting device (13) to the plastic working device (15), and the plastic working device (15) performs plastic working on the extruded material (17a) conveyed by the conveyance device (14) to form an aluminum alloy part.

Owner:KOBE STEEL LTD

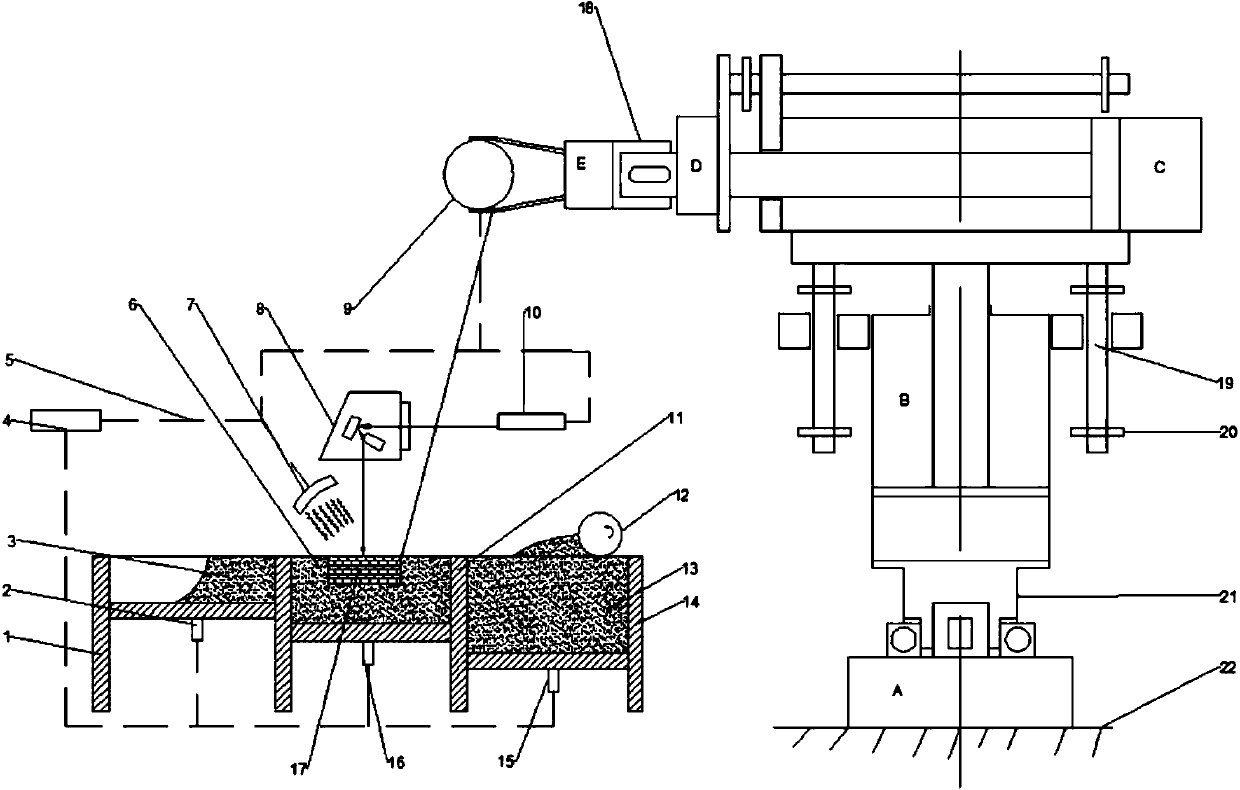

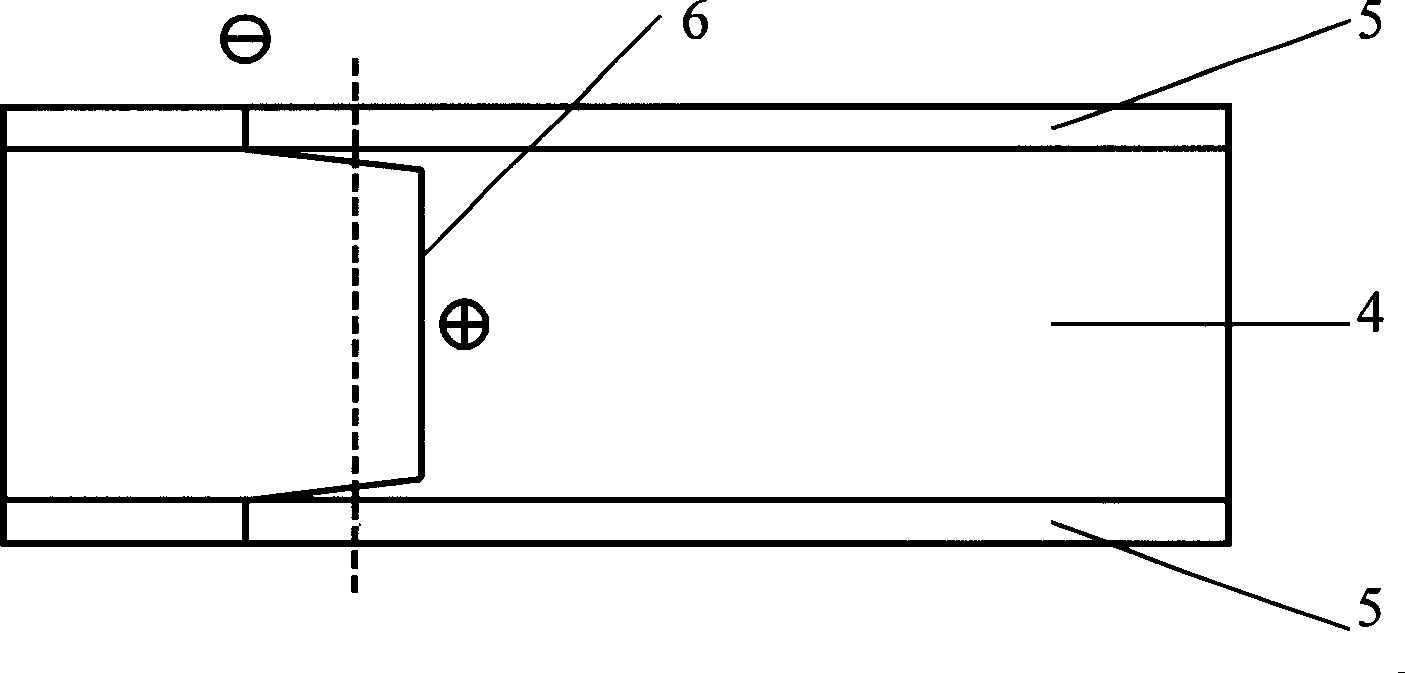

Shot peening system for inner wall of steel cylinder

InactiveCN102626905AIncreased fatigue strength limitImproved resistance to stress corrosion crackingAbrasive feedersAbrasive machine appurtenancesEngineeringKinetic energy

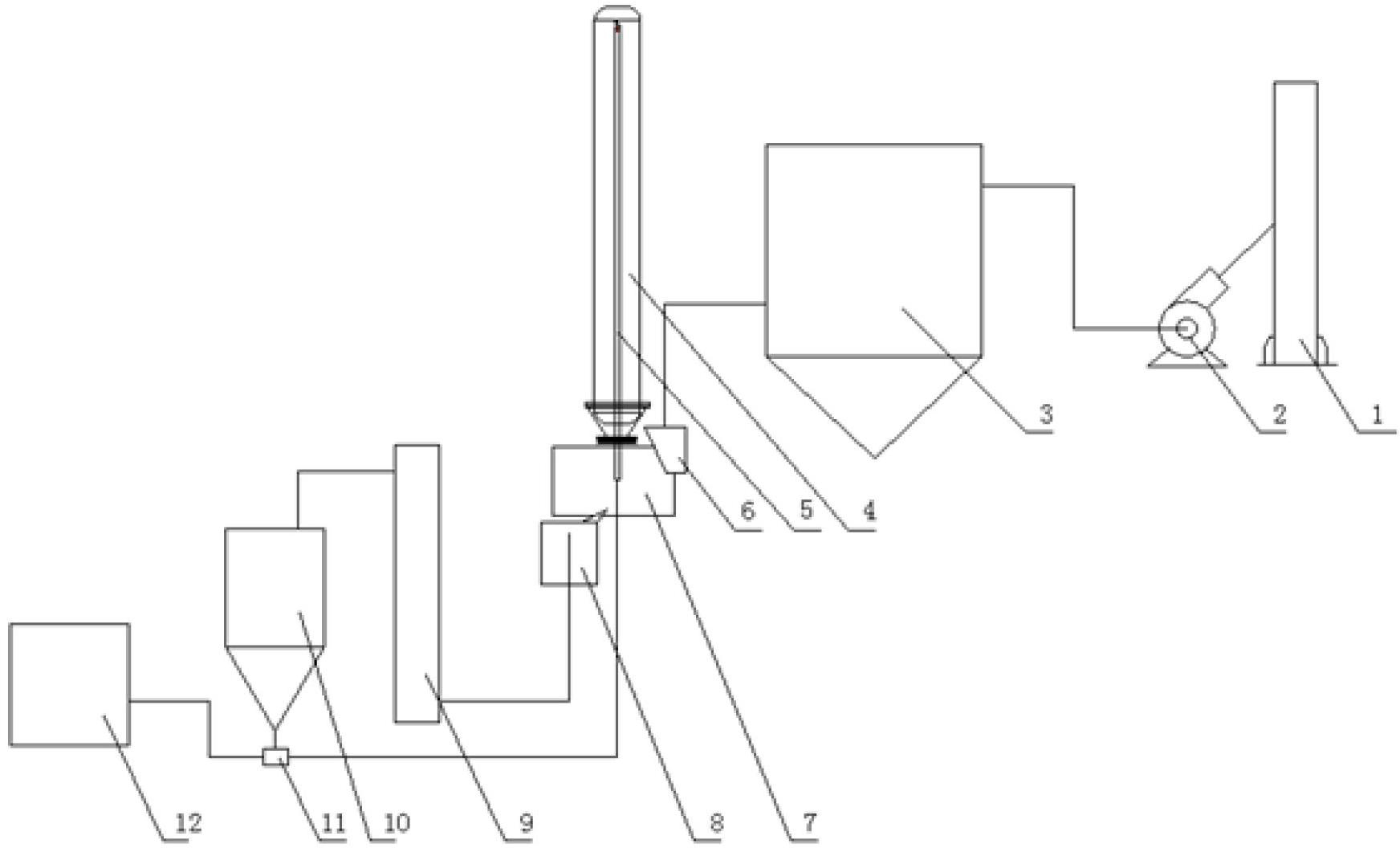

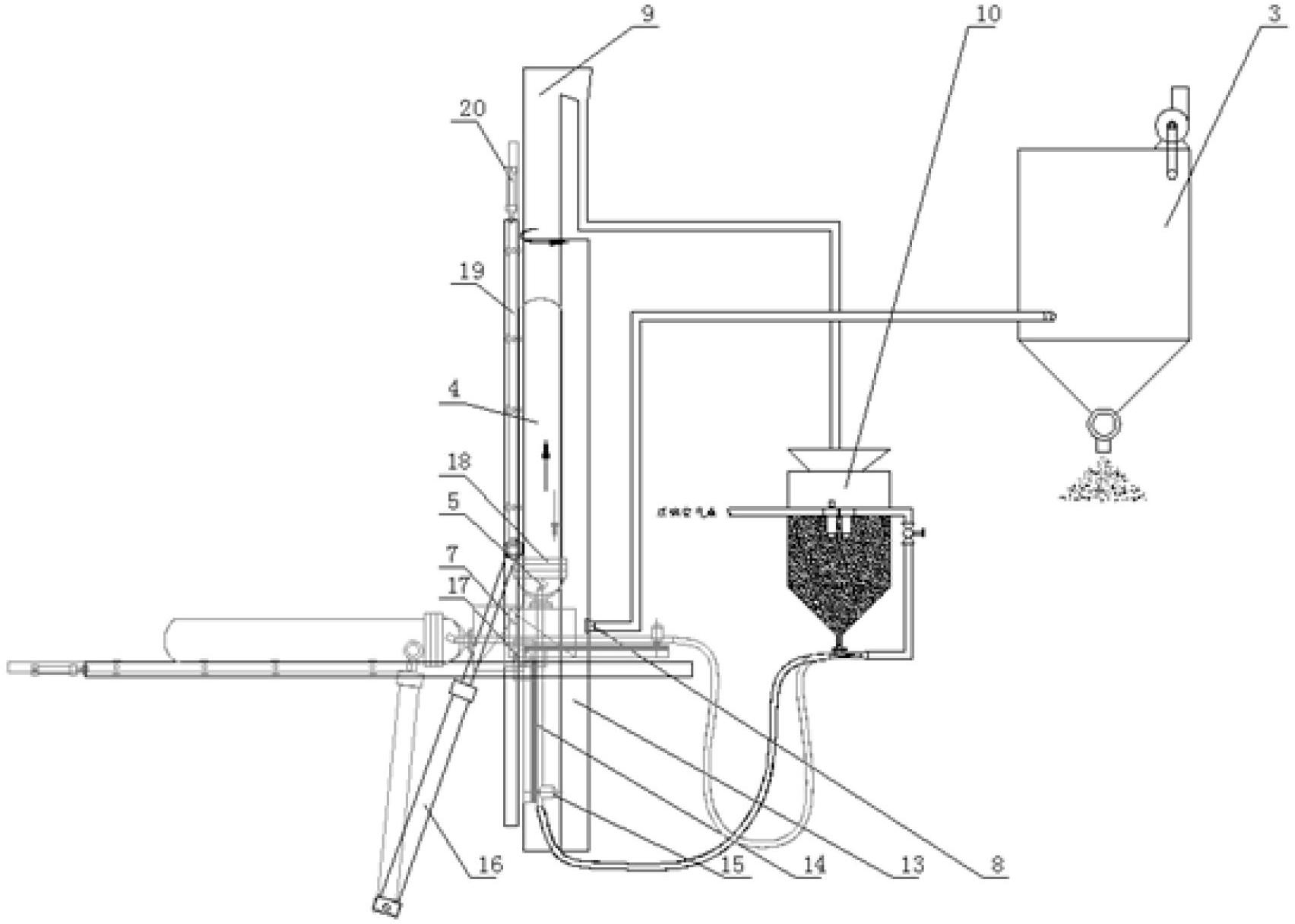

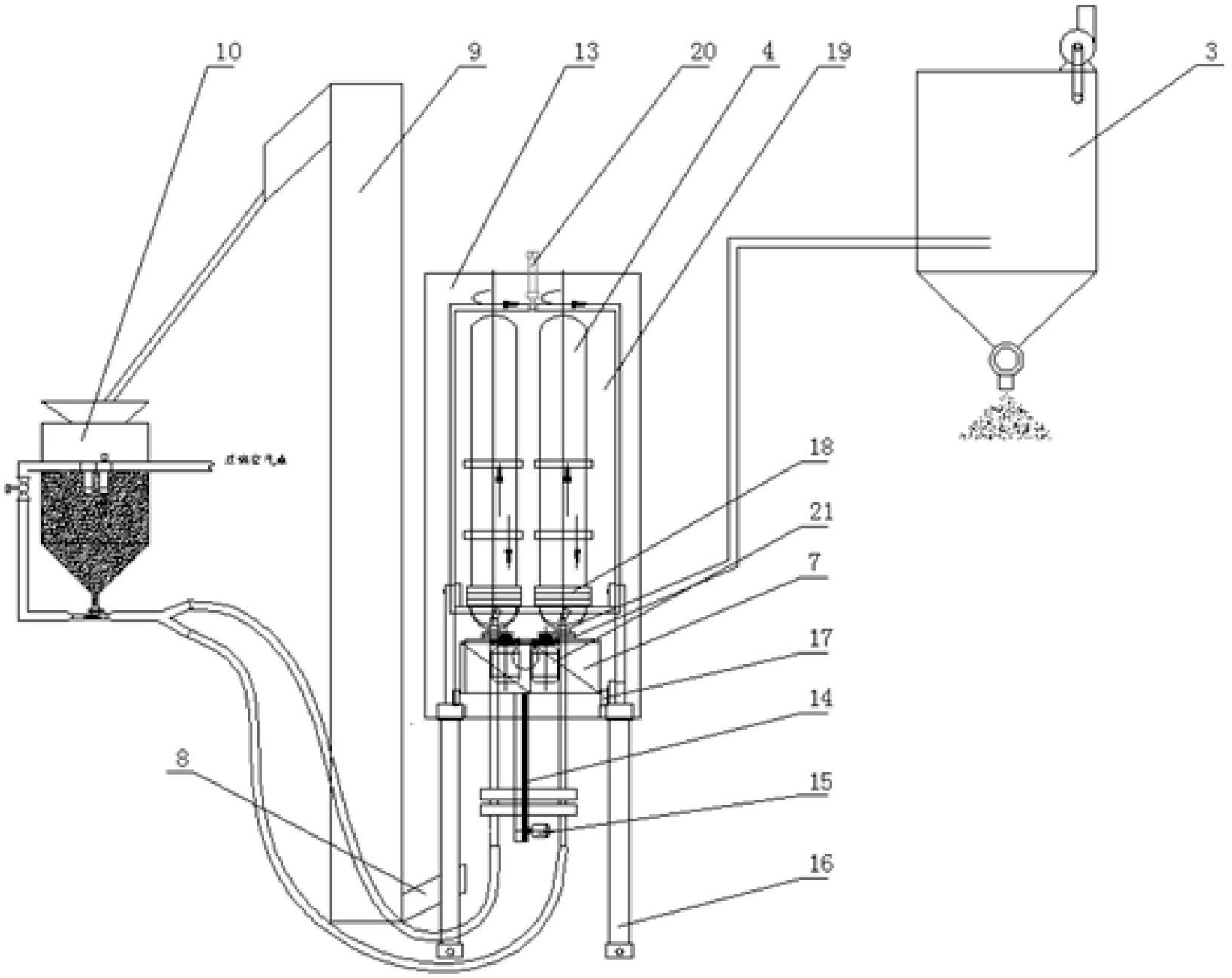

The invention relates to a shot peening system for an inner wall of a steel cylinder, which comprises a compressed air source, a sand-blasting tank, a recovery bucket elevator, a recovery bucket, a driving device, a dedusting hood, the steel cylinder, a sand-blasting gun, a sand-blasting processing device, a deduster, a fan and a chimney, wherein the compressed air source is used for feeding blasting shots in the connected sand-blasting tank into the sand-blasting gun of the sand-blasting processing device through a sand-blasting valve of the sand-blasting tank; the sand-blasting gun is coaxially placed in the steel cylinder; the steel cylinder is connected with the recovery bucket; the recovery bucket is connected with the recovery bucket elevator; the recovery bucket elevator is connected with the sand-blasting tank; the sand-blasting gun is driven by the sand-blasting processing device to displace axially; and gas in the steel cylinder is collected by the dedusting hood so as to be fed into the deduster and is discharged by the fan through the chimney. According to the shot peening system, compressed air is adopted as driving force, and sand blasting is accelerated to generate a certain kinetic energy which is sprayed to the inner wall of the steel cylinder, so that scales (iron rust) on the inner wall of the steel cylinder, turning residues and attachments generated by stretching in the inner wall of the steel cylinder are cleaned; a bright and clean metal surface is obtained through processing; and the smooth finish reaches sa2.0-2.5(GB8923-88).

Owner:TIANJIN ZHAOYANG TECH CO LTD

Cr(CO)6 modified low-zinc hot-dip aluminum alloy coating material

InactiveCN103146965AImproved resistance to stress corrosion crackingHarm reductionHot-dipping/immersion processesAlloy coatingZinc

The invention discloses a Cr(CO)6 modified low-zinc hot-dip aluminum alloy coating material. Based on element weight percentage, the alloy is composed of 20%-30% of Zn, 0.01%-0.15% of Pd, 1.5%-3.8% of Cu, 0.01%-0.05% of Sn, 0.1%-0.3% of a grain refining agent, 0.01%-0.1% of rear earth additive Pr, 0.01%-2.0% of Fe, and the balance being Al and inevitable trace impurities; and a modifier Cr(CO)6 accounts for 0.001% of to 0.01% of the total amount of furnace charging materials. The low-zinc, high-performance and hot-dip aluminum alloy coating material with Zn substituted by Al has relatively high overall performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

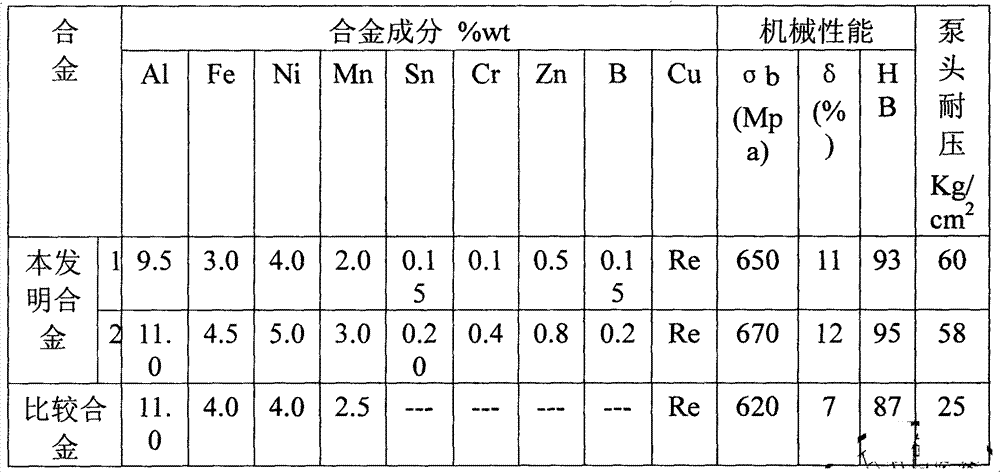

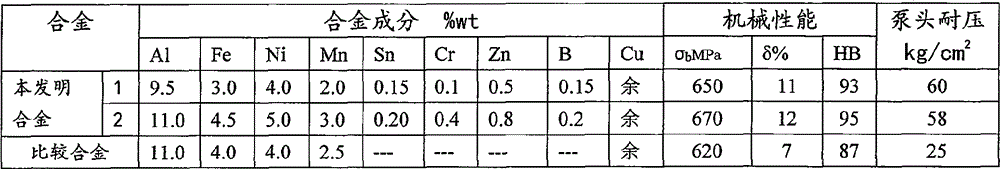

Aluminium bronze of sand-casting high-pressure pump head

InactiveCN103088231AImprove compactnessImproved resistance to stress corrosion crackingNonferrous metalSand casting

The invention provides aluminium bronze of a sand-casting high-pressure pump head, belonging to the technical field of new non-ferrous materials. The aluminium bronze comprises 9-11.5 % of Al, 2.5-5.0 % of Fe, less than or equal to 3.5 % of Mn, 3.0-6.0 % of Ni, 0.05-0.2 % of Sn, 0.01-0.5 % of Cr, 0.5-1.0 % of Zn, 0.015-0.2 %, and the balance being Cu and less than 1 % of usual impurities. The alloy is high in mechanical properties and pressure resistance of castings, and can be used in related fields of high-voltage submersible pump heads.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

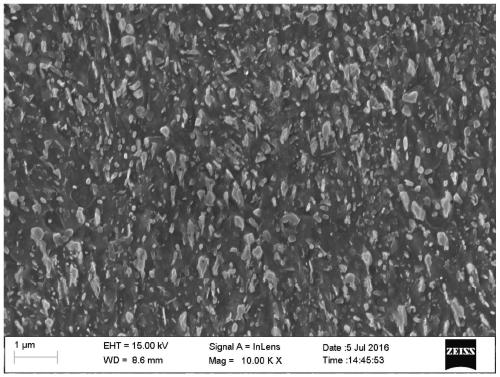

Method for increasing stress corrosion resistance of Fe-Ni-based anticorrosion alloy oil well pipe

ActiveCN109234500AReduce development costsImproved resistance to stress corrosion crackingFurnace typesHeat treatment furnacesCrack resistanceCold hardening

A method for increasing the stress corrosion resistance of a Fe-Ni-based anticorrosion alloy oil well pipe comprises the following steps: I, preparing a blank pierced billet for a cold hardening typeFe-Ni-based anti-corrosion alloy oil well pipe through hot working modes such as hot extrusion or hot rolling; II, preparing the cold hardening type Fe-Ni-based anti-corrosion alloy oil well by adopting a two-pass or multi-pass Pilger cold rolling mode; III, carrying out solid-solution annealing among all passes of cold working, and removing a cold hardening effect of a pipe; IV, enabling the deformation rate of final-pass cold rolling to be 56.5 percent or more; V, enabling the feeding amount of the final-pass cold rolling to be 5mm every time or more and the rolling frequency to be 20 per minute or more; VI, slowly cooling an oil well pipe prepared through the final-pass cold rolling to room temperature through an asbestos covering or sand covering mode. According to the method disclosedby the invention, the stress corrosion cracking resistance of the cold hardening type Fe-Ni-based anti-corrosion alloy oil well in H2S medium environment can be remarkably increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

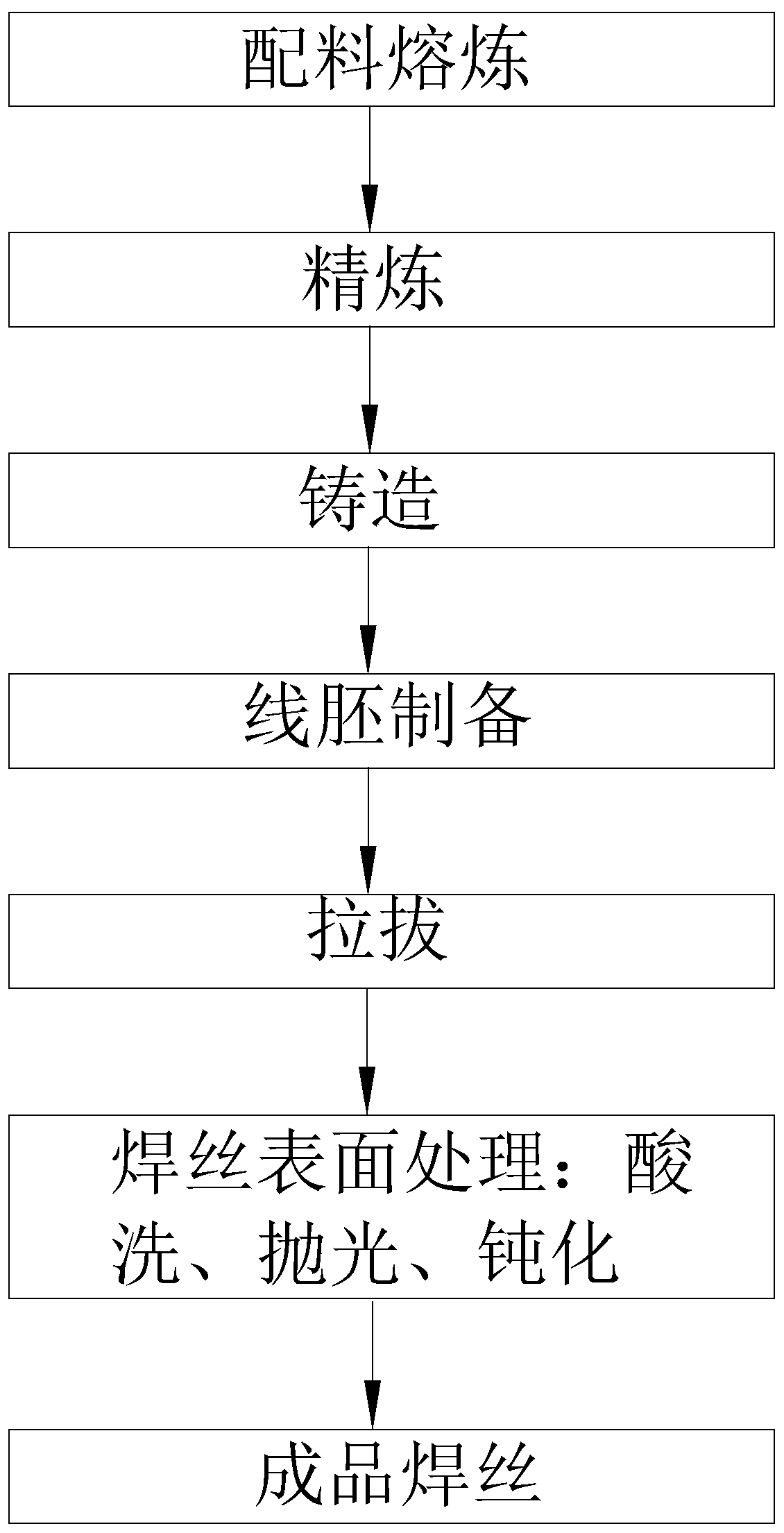

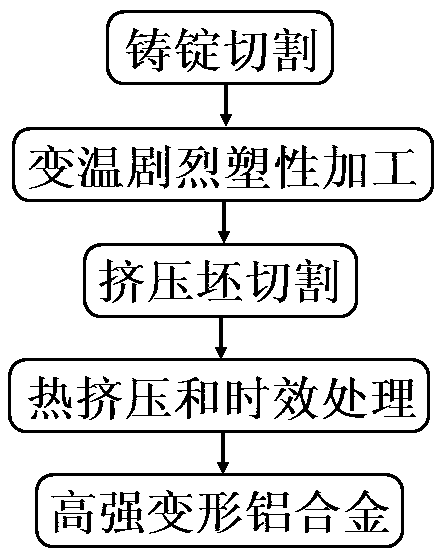

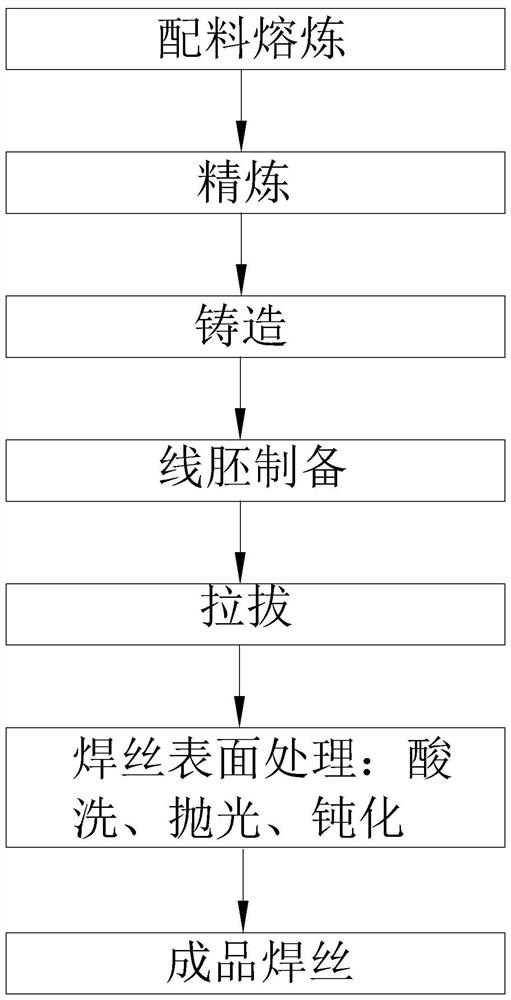

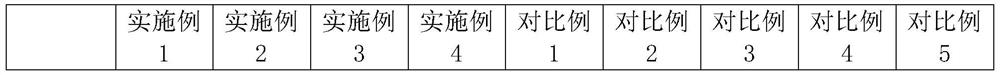

Ultralow-carbon high-temperature-resistant welding wire and preparation method thereof

ActiveCN110551951AReduce formationReduce intergranular corrosionWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention relates to an ultralow-carbon high-temperature-resistant welding wire and a preparation method thereof. The ultralow-carbon high-temperature-resistant welding wire comprises the following chemical components, in percentage by mass, of 0.01%-0.04% of C, 22.0%-24.0% of Cr, 1.5%-3.5% of Si, 12.0%-14.0% of Ni, 0.5%-1.2% of Ti, 0.1%-0.4% of Mn, 0.2%-0.5% of Zr, 0.3%-0.6% of Sc, 0.1%-0.3%of Mo, 0.3%-0.5% of Nb, 3.0%-5.0% of Mg, 0.6%-1.2% of Al, 0.03%-0.07% of P, 0.02%-0.05% of S, 0.2%-0.4% of V, 1.3%-1.6% of B, and the balance Fe and other inevitable impurity elements. According to the method, the mechanical property of the welding wire can be improved while the low carbon of the welding wire is ensured.

Owner:常州长海焊材有限公司

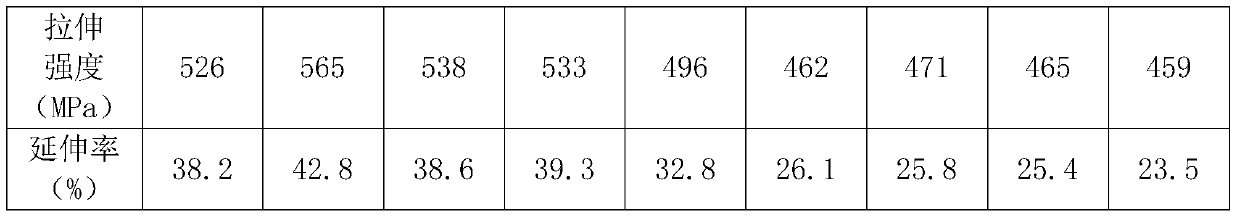

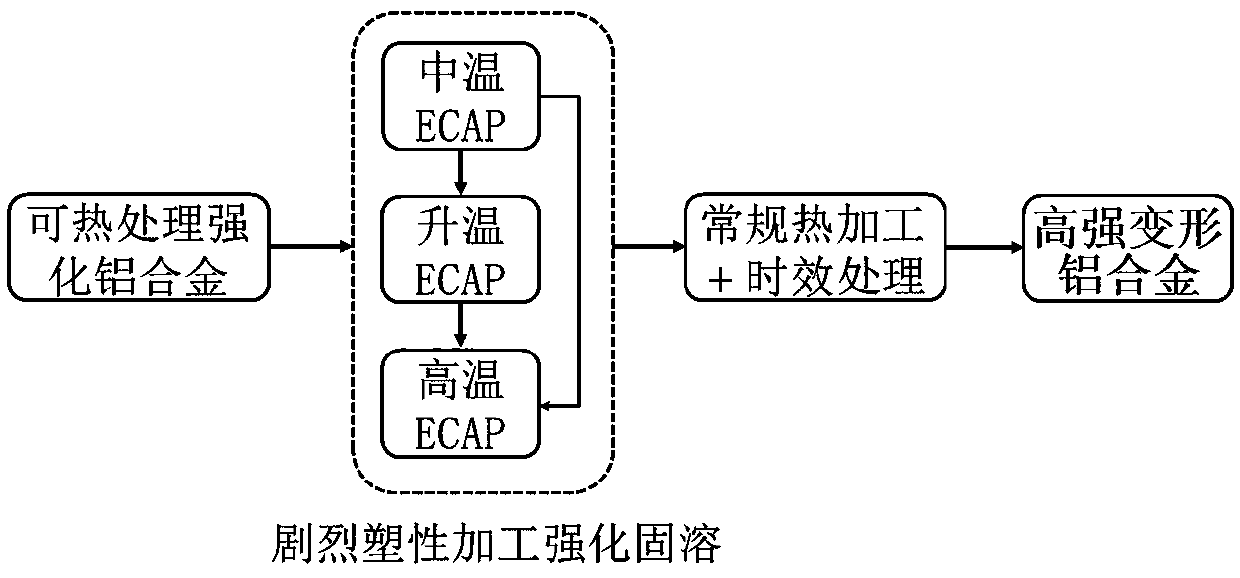

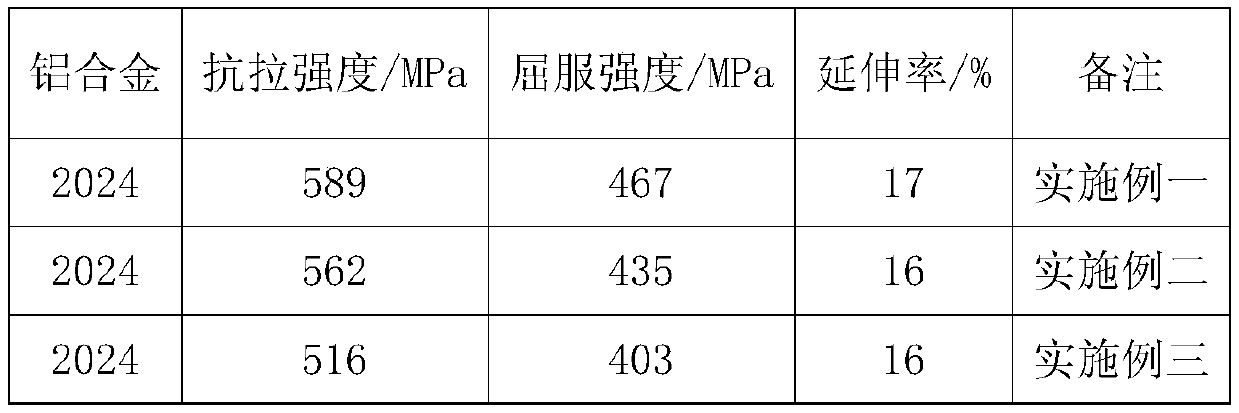

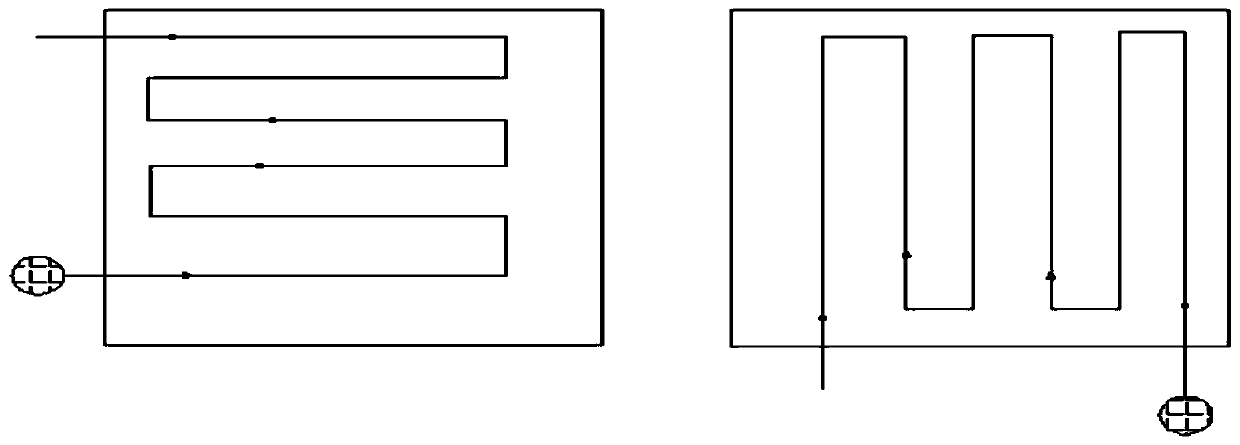

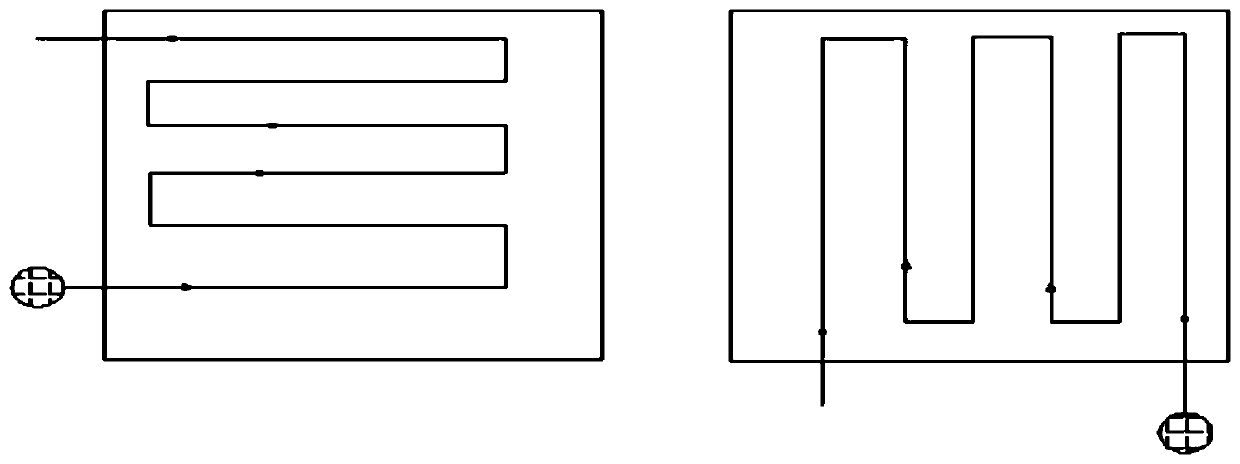

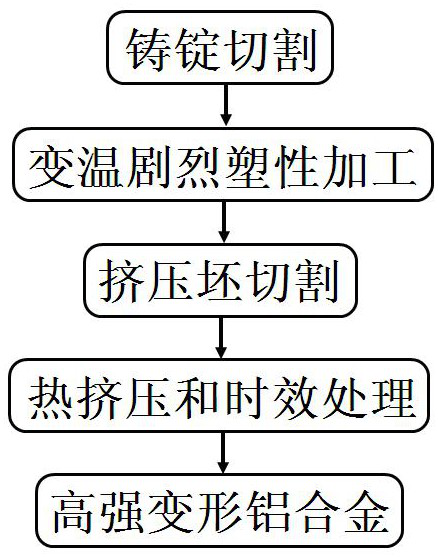

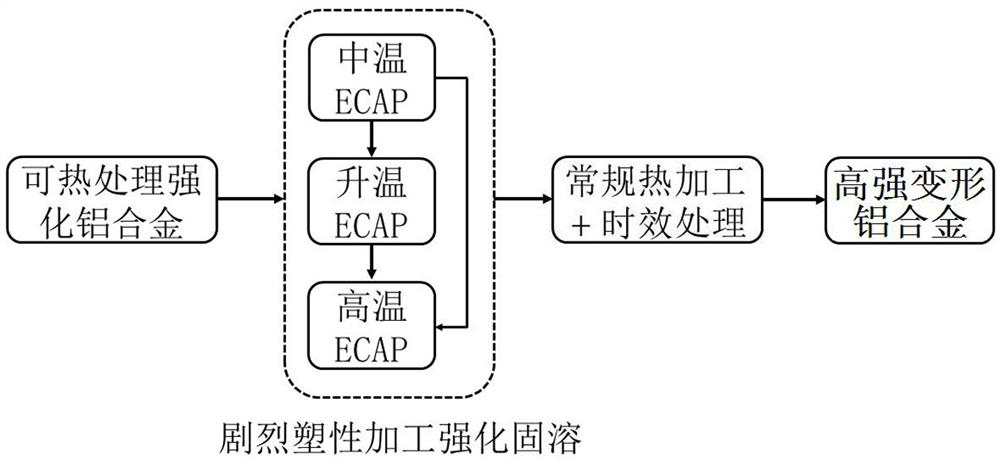

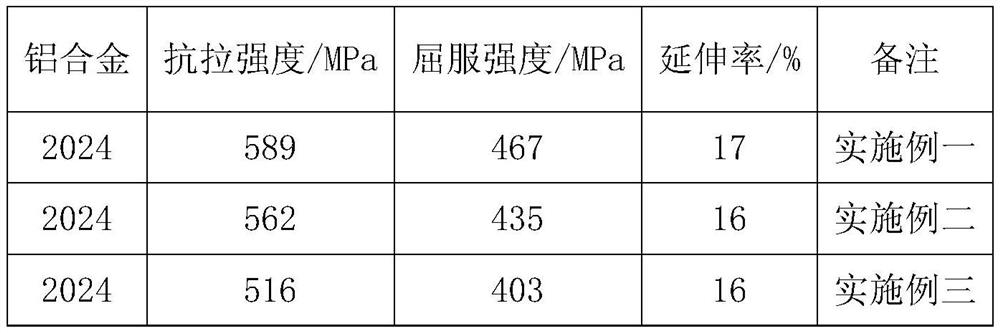

Method for preparing high-strength wrought aluminum alloy based on severe plastic deformation

The invention discloses a method for preparing a high-strength wrought aluminum alloy based on severe plastic deformation. The method comprises the following steps that A, a blank is cut out from an aluminum alloy cast ingot; B, the blank is put into a rotary die equal channel angular pressing die, equal channel angular pressing processing is continuously carried out by adopting multi-temperaturestages of step-by-step temperature rise, strengthened solid solution treatment is realized by using a severe plastic deformation technology, and after completion, water quenching treatment is carriedout so as to obtain a supersaturated solid solution block extrusion billet; and C, an alloy bar with the length direction parallel to the equal-channel angular pressing direction is cut out, and conventional hot extrusion processing and aging treatment are carried out on the alloy bar so as to obtain the high-strength wrought aluminum alloy. According to the method, strengthened solid solution treatment is realized through staged severe plastic deformation of step-by-step temperature rise, a second phase is effectively promoted to dissolve, a single-phase solid solution alloy with fine grain size, high density defects and high supersaturation degree is obtained, then uniform precipitation of a nano precipitation phase is promoted through hot working and aging treatment, and the high-strength wrought aluminum alloy is obtained.

Owner:江苏江南创佳型材有限公司

Low-zinc hot-dip-coating aluminum alloy coating material achieving alteration by chrome coordination compound

InactiveCN103131996AInhibition of chemical reactionsQuality improvementHot-dipping/immersion processesDip-coatingAlloy coating

The invention discloses low-zinc hot-dip-coating aluminum alloy coating material achieving alteration by chrome coordination compound. The low-zinc hot-dip-coating aluminum alloy coating material achieving the alteration by chrome coordination compound comprises, by weight, 3.25% of chrome coordination compound Cr (CO) 6, 30% of Zn, 1.0% of Si, 0.7% of tombarthite additives, and balanced Al and unavoidable trace impurities. The low-zinc hot-dip-coating aluminum alloy coating material achieving the alteration by chrome coordination compound solves the problems that steel plate needle-shaped coating leakage can occur to zinc-aluminum coating material and a coating layer can not effectively protect cathodes of a scratch and a notch and also achieves the performances, such as forming machining, welding and coating, of the zinc-aluminum coating material.

Owner:贵州铝厂有限责任公司

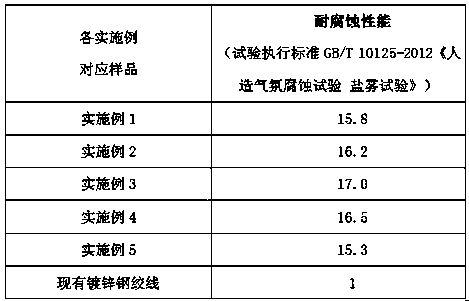

Steel core wire anticorrosive alloy coating for overhead conductor and preparation method thereof

ActiveCN109371285AStrong corrosion resistanceImprove corrosion resistanceHot-dipping/immersion processesChromiumAluminium

The invention relates to a steel core wire anticorrosive alloy coating for an overhead conductor and a preparation method of the steel core wire anticorrosive alloy coating. The steel core wire anticorrosive alloy coating comprises, by weight, 5-10% of aluminium, 0.005-0.2% of rare earth, 0.005-0.2% of silver, 0.05-0.5% of manganese, 0.05-1.0% of chromium and the balance of zinc and inevitable impurities. Alloy coatings prepared according to the proportion of the steel core wire anticorrosive alloy coating are excellent in corrosion resistance, namely, taking the occurrence time of yellow rustas the failure standard of the alloy coatings, under the condition that the thicknesses of the coatings are the same, the corrosion resistance of the steel core wire anticorrosive alloy coating is 15times higher than that of a hot-dip pure zinc coating; and taking weight loss in a salt spray test as the standard of testing the corrosion resistance of the alloy coatings, under the condition thatthe thicknesses of the coatings are the same, the corrosion resistance of steel core wire anticorrosive alloy coating is 15 times higher than that of an industrial hot-dip pure zinc coating.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +3

Corrosion-resisting prestress pipeline steel wire

InactiveCN106893948AImprove corrosion resistanceImproved resistance to stress corrosion crackingStress corrosion crackingMetal

The invention relates to a corrosion-resisting prestress pipeline steel wire. The corrosion-resisting prestress pipeline steel wire is invented for mainly solving the problem that a current pipeline steel wire is broken due to stress corrosion cracking. The steel wire comprises metal elements including, by total weight percent, 0.15%-0.50% of Cr, 0.05%-0.10% of V, 0.10%-1.00% of Ni, 0.10%-0.50% of Cu, 0.79%-0.83% of C, 0.12%-0.32% of Si, 0.60%-0.90% of Mn, smaller than or equal to 0.025% of S, smaller than or equal to 0.025% of P and the balance Fe. The steel wire production technology is the same as the existing SWRH82B steel wire production technology. The corrosion-resisting prestress pipeline steel wire has the beneficial effect that the corrosion resisting capability of the steel wire is improved.

Owner:辽宁通达建材实业有限公司

Corrosion prevention method of rare earth-containing alloy coating used for ground net protection

InactiveCN104831225AQuality improvementImprove corrosion resistanceMolten spray coatingManganeseCerium

The invention discloses a corrosion prevention method of a rare earth-containing alloy coating used for ground net protection, and relates to the conductive coating corrosion prevention field, according to the method, plasma spraying technology is used, carbon steel is used as a ground net material, and the ground net surface is successively sprayed with a cohesive bottom layer with the thickness of 60-100 microns and a lanthanum, cerium, praseodymium, neodymium and other rare earth-containing functional alloy surface layer with the thickness of 150-200 microns. The method comprises the following steps: (1) purification decontamination and sandblasting processing of the ground net surface; (2) allocation of lanthanum, cerium, praseodymium, neodymium and other rare earth-containing alloy powder in zinc, aluminum, magnesium, nickel, manganese, silicon, chromium, beryllium and titanium alloy powder of a surface layer coating; and (3) formation of the rare earth-containing alloy corrosion prevention coating. The electric power ground net surface is sprayed with the rare earth-containing alloy corrosion prevention coating, so that the ground net service life is improved, the ground net work cost is reduced, and the method is simple and reliable in process, green, low-carbon, non-pollution, and friendly to environment.

Owner:STATE GRID CORP OF CHINA +3

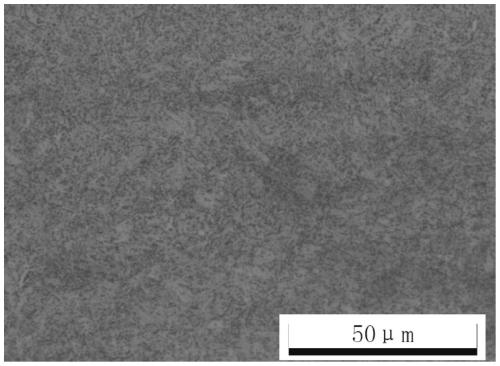

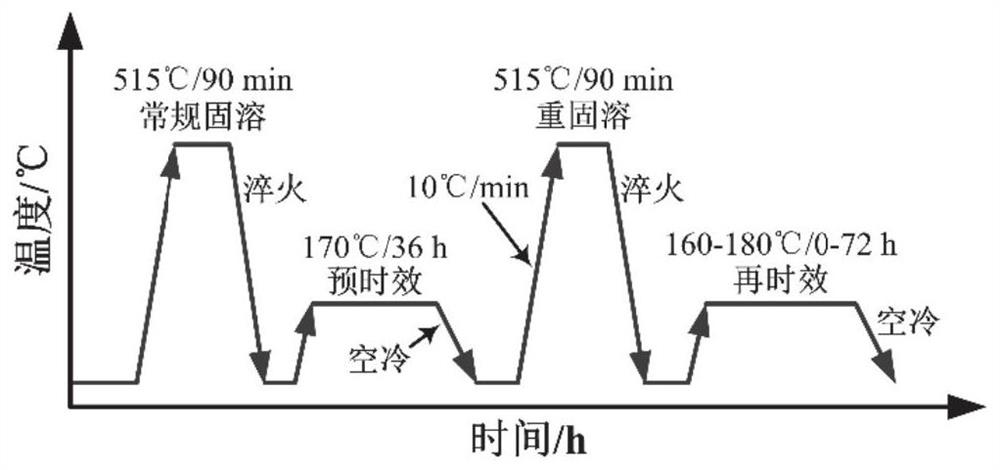

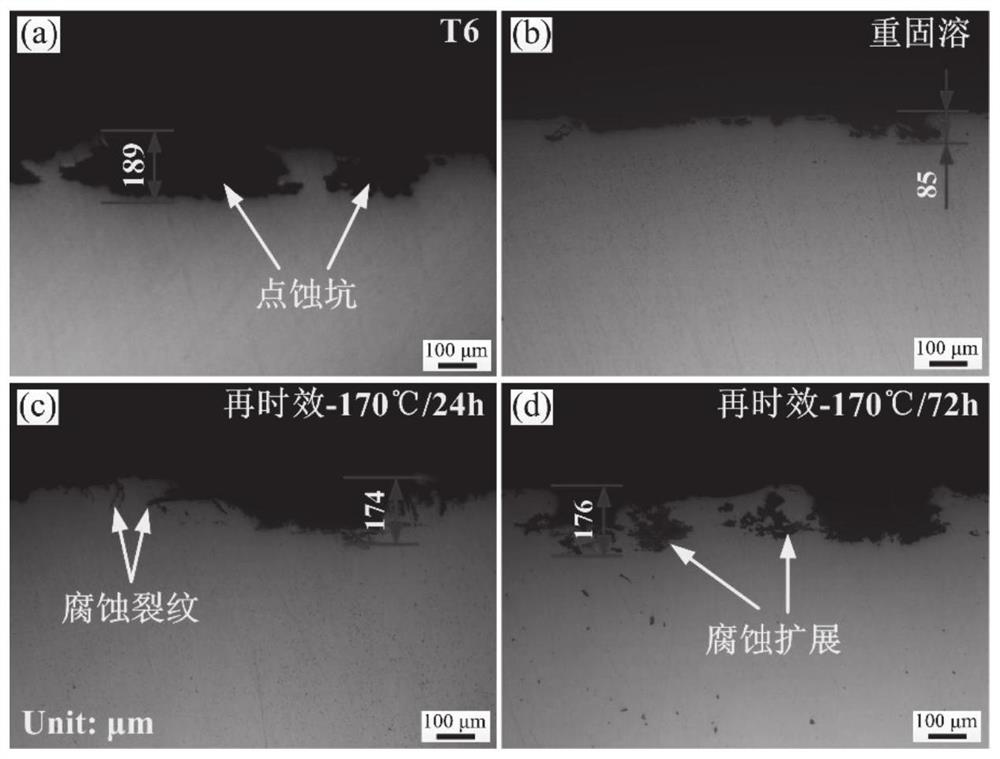

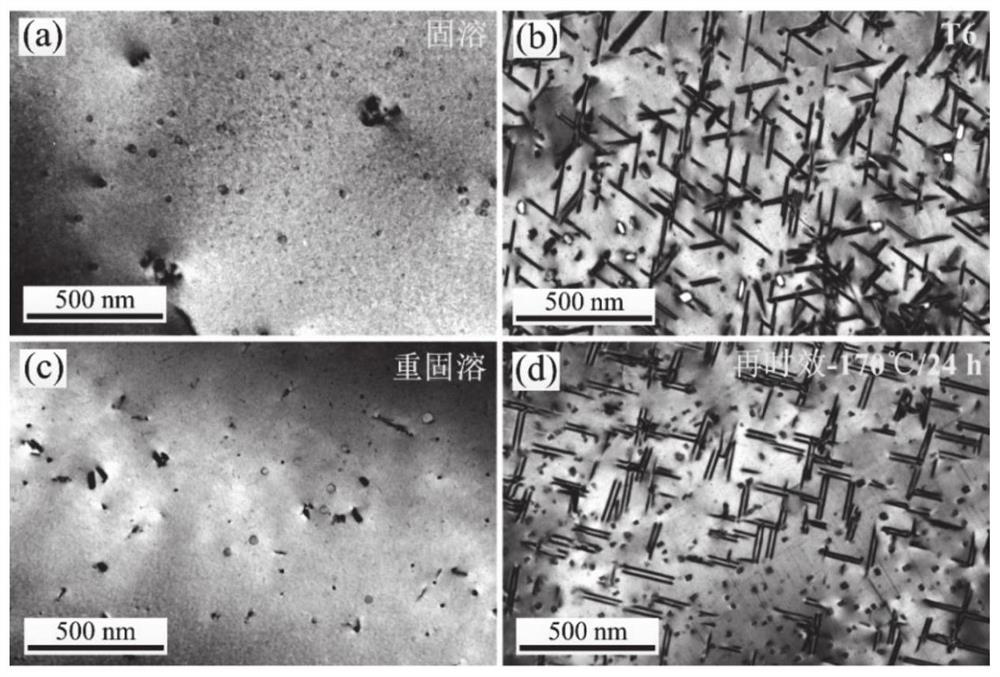

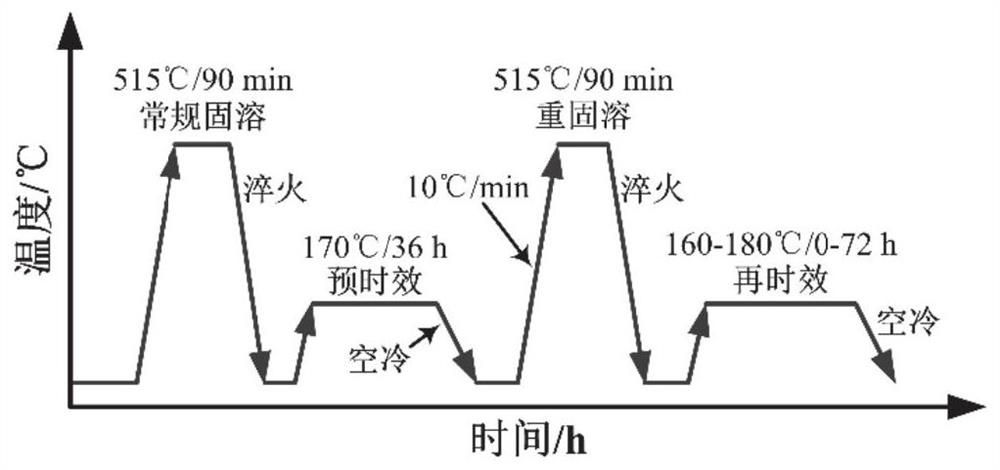

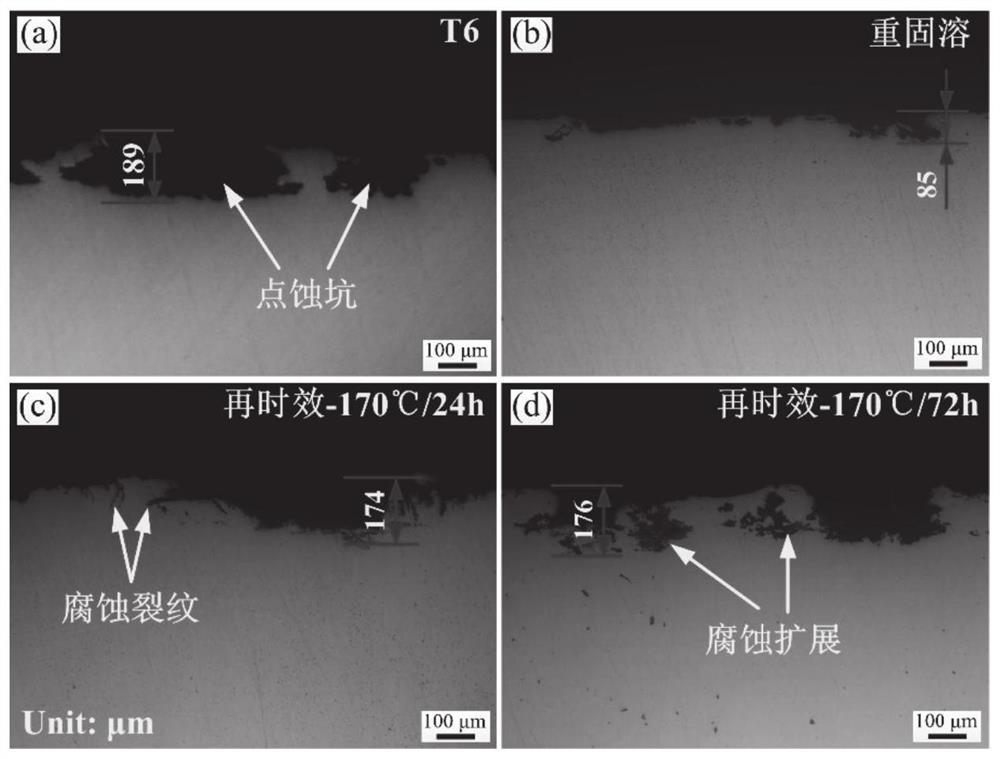

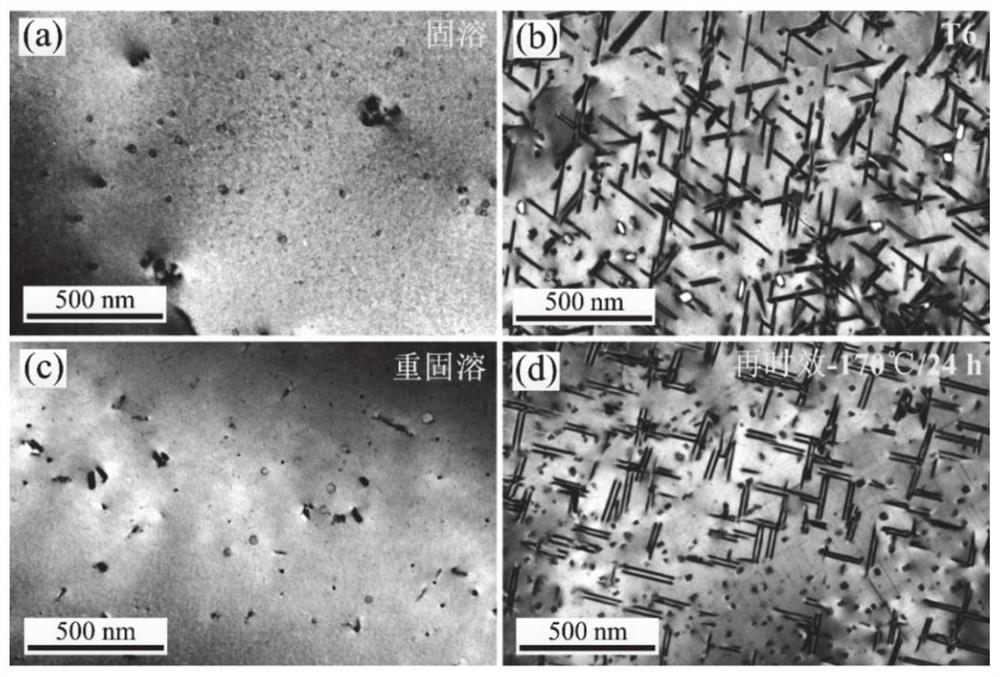

Heat treatment method for pre-aging, re-solid-solution and re-aging of Al-Cu-Li alloy

ActiveCN112281092AReduce the effect of strengtheningHigh strengthSolution treatmentHeat conservation

The invention discloses a heat treatment method for pre-aging, re-solid-solution and re-aging of an Al-Cu-Li alloy, belongs to the field of material heat treatment, and aims to perform conventional solid-solution, pre-aging, re-solid-solution and re-aging treatment on an Al-Cu-Li alloy extruded plate by controlling a heat treatment process system and parameters thereof. The conventional solid solution and re-solid solution treatment temperature is 515 + / -10 DEG C, heat preservation is performed for 60-90 min, then water quenching is performed, and the quenching transfer time is shorter than 5s. The pre-aging and re-aging treatment temperature is 160-180 DEG C, heat preservation is performed for 24-48 hours, and the product is taken out for air-cooling. The strength of the alloy can be reduced through re-solid-solution treatment, the plasticity of the alloy is improved, and correction and reprocessing processes are facilitated. The re-aging treatment can effectively regulate and control the variety, density and distribution of precipitated phases, thereby enhancing the strength of the alloy. In addition, due to coarsening of discontinuous grain boundary precipitated phases in the alloy and increasing of the copper content, on the premise that the strength of the alloy is basically not lost, the stress corrosion resistance, the intergranular corrosion resistance and the electrochemical corrosion resistance are improved, and the plasticity of the alloy is improved. The process is simple and feasible and is not limited by the thickness of the plate.

Owner:SHANDONG UNIV

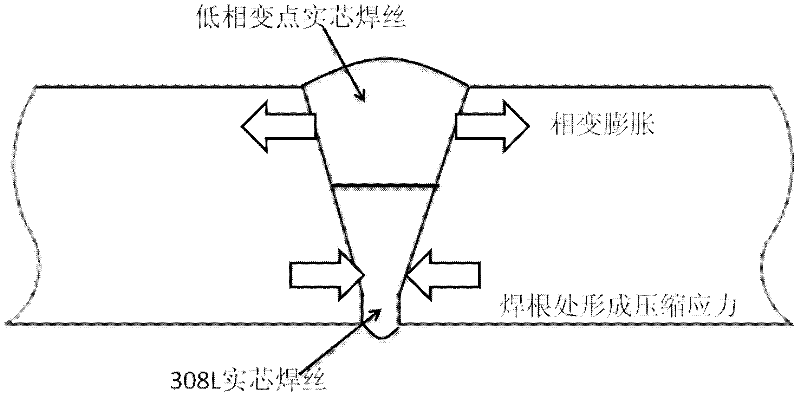

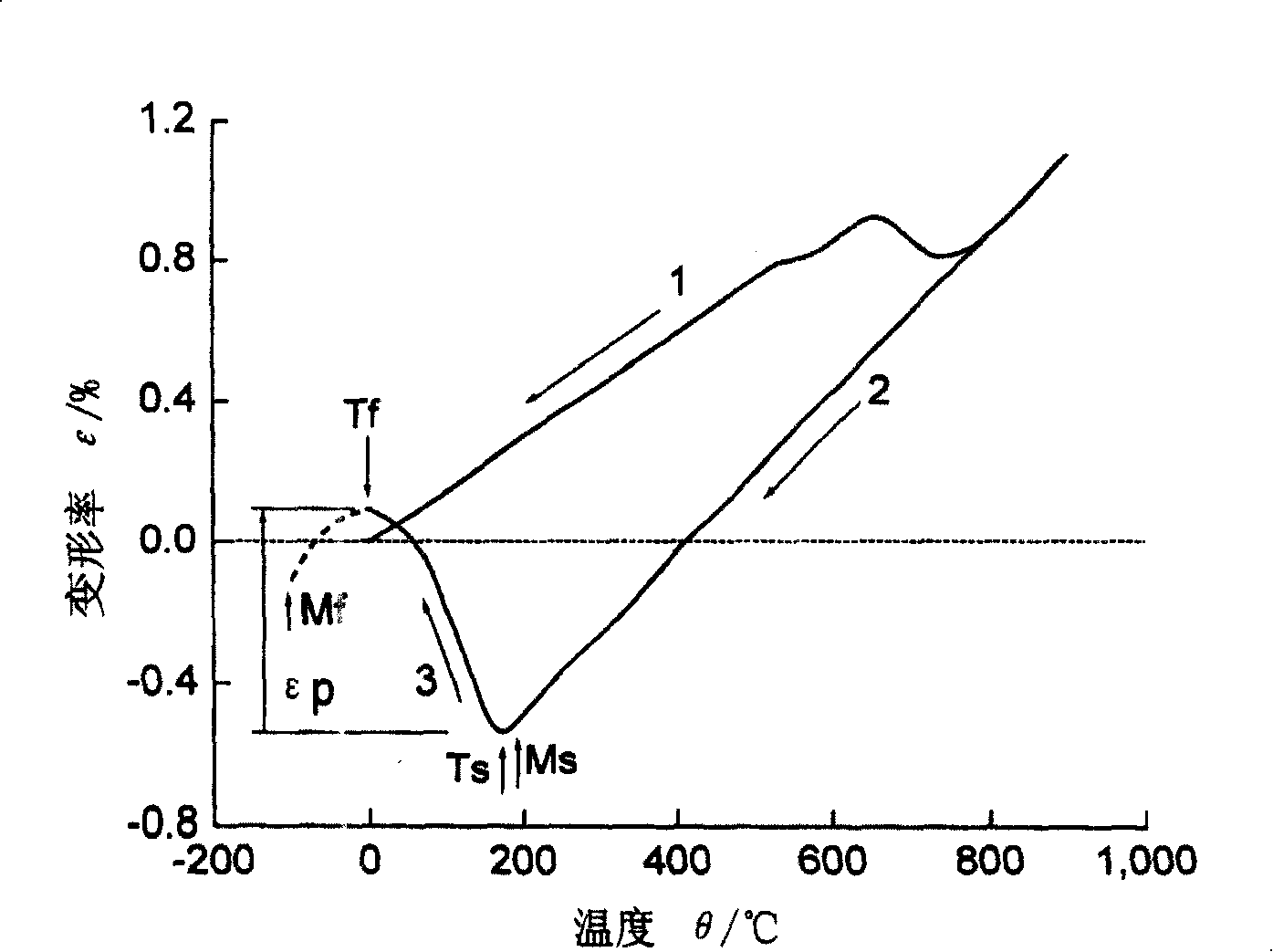

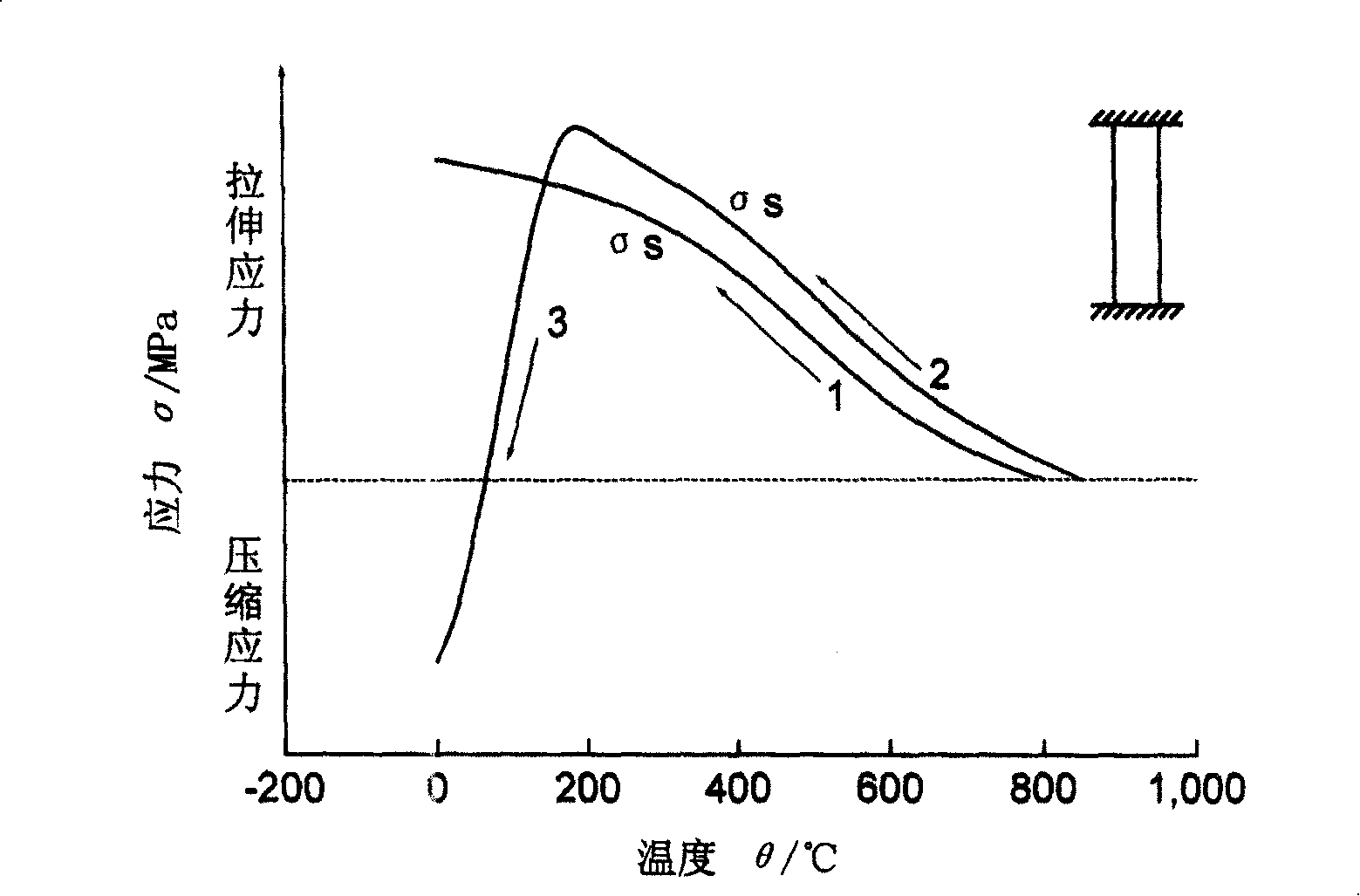

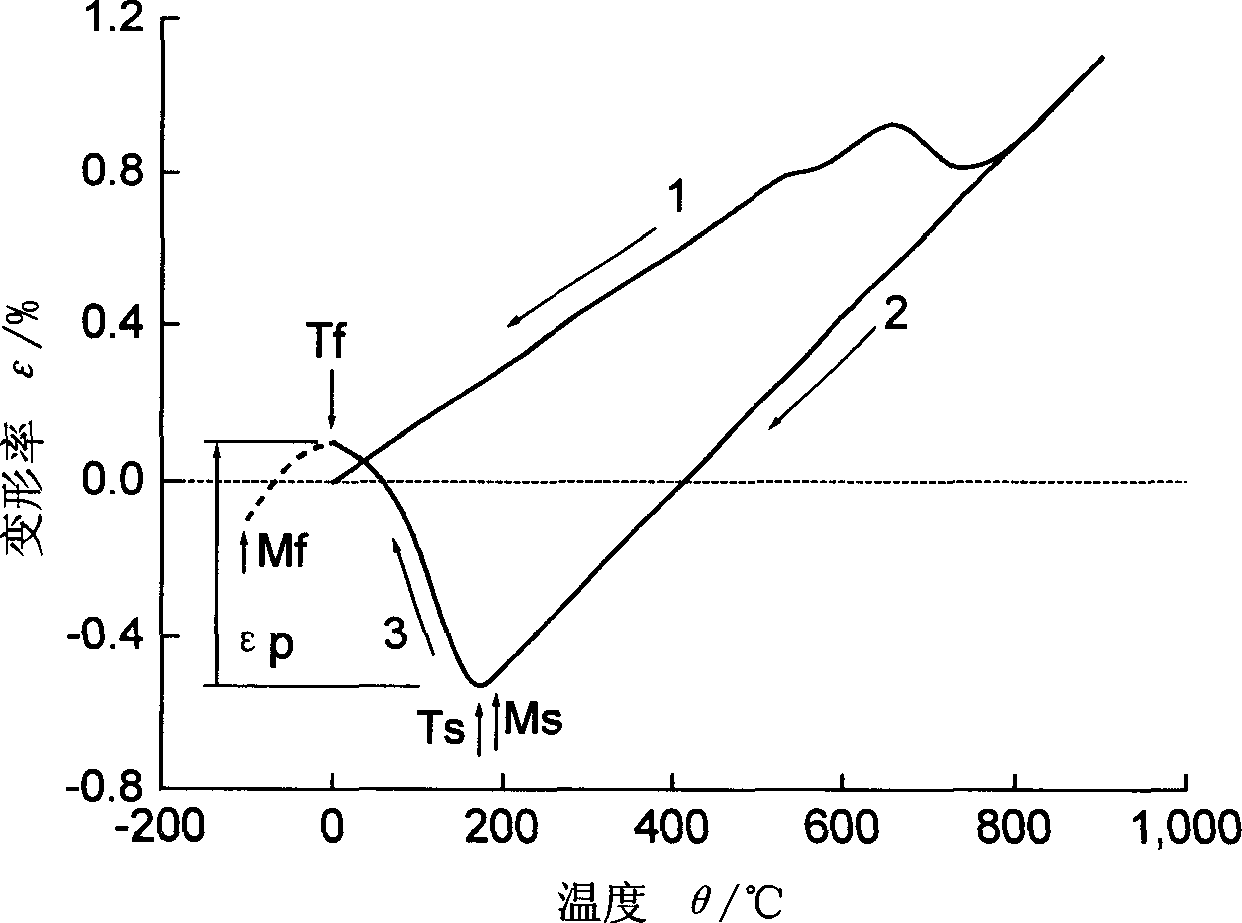

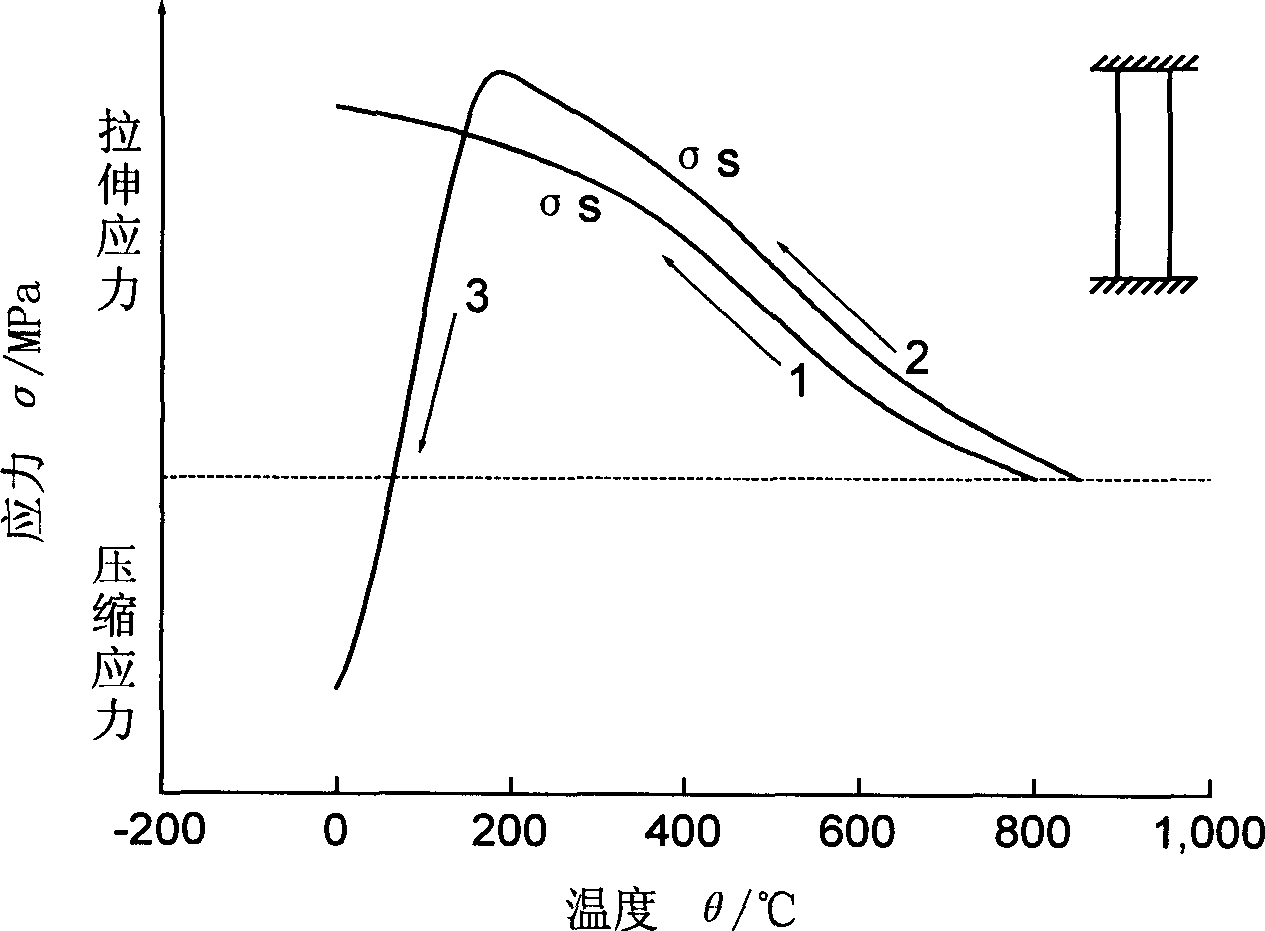

Welding process method for improving stress corrosion resistance of stainless steel pipe inner wall welding joint

InactiveCN102581448AImproved resistance to stress corrosion crackingAvoid corrosion damageArc welding apparatusWelding/cutting media/materialsWelding jointStress corrosion cracking

The invention discloses a welding process method for improving stress corrosion resistance of a stainless steel pipe inner wall welding joint. When a stainless steel pipe is welded, a front half section is provided with a common stainless steel wire while a rear half section is provided with a low transformation temperature solid wire to replace an original stainless steel wire, and compressive stress is generated at the weld root of the inner wall of the stainless steel pipe under the action of low-temperature phase transformation expansion. By the aid of the technical scheme, an inner wall seam of the steel pipe contacting with corrosion media has alloy components the same as that of a conventional welding method, and the compressive stress can be generated at the weld root of the inner wall of the steel pipe, so that the stress corrosion cracking resistance of the welding joint is improved.

Owner:TIANJIN UNIV

A kind of ultra-low carbon high temperature resistant welding wire and preparation method thereof

ActiveCN110551951BReduce formationReduce intergranular corrosionWelding/cutting media/materialsSoldering mediaImpurityMaterials science

The invention relates to an ultralow-carbon high-temperature-resistant welding wire and a preparation method thereof. The ultralow-carbon high-temperature-resistant welding wire comprises the following chemical components, in percentage by mass, of 0.01%-0.04% of C, 22.0%-24.0% of Cr, 1.5%-3.5% of Si, 12.0%-14.0% of Ni, 0.5%-1.2% of Ti, 0.1%-0.4% of Mn, 0.2%-0.5% of Zr, 0.3%-0.6% of Sc, 0.1%-0.3%of Mo, 0.3%-0.5% of Nb, 3.0%-5.0% of Mg, 0.6%-1.2% of Al, 0.03%-0.07% of P, 0.02%-0.05% of S, 0.2%-0.4% of V, 1.3%-1.6% of B, and the balance Fe and other inevitable impurity elements. According to the method, the mechanical property of the welding wire can be improved while the low carbon of the welding wire is ensured.

Owner:常州长海焊材有限公司

A Method for Improving Stress Corrosion Resistance of Iron-Nickel-Based Corrosion-Resistant Alloy Oil Well Pipe

ActiveCN109234500BReduce development costsImproved resistance to stress corrosion crackingFurnace typesHeat treatment furnacesFernicoCold hardening

A method for increasing the stress corrosion resistance of a Fe-Ni-based anticorrosion alloy oil well pipe comprises the following steps: I, preparing a blank pierced billet for a cold hardening typeFe-Ni-based anti-corrosion alloy oil well pipe through hot working modes such as hot extrusion or hot rolling; II, preparing the cold hardening type Fe-Ni-based anti-corrosion alloy oil well by adopting a two-pass or multi-pass Pilger cold rolling mode; III, carrying out solid-solution annealing among all passes of cold working, and removing a cold hardening effect of a pipe; IV, enabling the deformation rate of final-pass cold rolling to be 56.5 percent or more; V, enabling the feeding amount of the final-pass cold rolling to be 5mm every time or more and the rolling frequency to be 20 per minute or more; VI, slowly cooling an oil well pipe prepared through the final-pass cold rolling to room temperature through an asbestos covering or sand covering mode. According to the method disclosedby the invention, the stress corrosion cracking resistance of the cold hardening type Fe-Ni-based anti-corrosion alloy oil well in H2S medium environment can be remarkably increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material

InactiveCN103131982BReduce solubilityGood casting performanceHot-dipping/immersion processesInterfacial reactionCerium

The invention discloses a multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material. The alloy comprises the following components: by weight, smaller than or equal to 15% of zinc (Zn), 0.5%-2.5% of silicon (Si), 3% of alloy enhancer copper (Cu), 0.5% of polarization alterant gold (Au), 0.5% of solvent passivator chrome (Cr), 0.3% of sediment hardening agent cadmium (Cd), 0.5% of grain refiner titanium (Ti), 0.5% of rare earth addition cerium (Ce), 1% of matrix interfacial reaction buffering agent, with the balance being aluminum (Al) and inevitable trace impurities. The Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material effectively solves the problem that the proportion of the hot-dip galvanizing occupying the zinc is high, and the zinc resource is saved. A great quantity of the aluminum is added to replace the zinc in the aluminum alloy coating material for hot dipping, due to the fact that the aluminum resource is rich and the cost is low, the comprehensive cost of the coating material is reduced.

Owner:GUIZHOU ACAD OF SCI

A kind of anti-corrosion method of rare earth alloy coating for grounding grid protection

InactiveCN104831225BQuality improvementImprove corrosion resistanceMolten spray coatingCeriumManganese

The invention discloses a corrosion prevention method of a rare earth-containing alloy coating used for ground net protection, and relates to the conductive coating corrosion prevention field, according to the method, plasma spraying technology is used, carbon steel is used as a ground net material, and the ground net surface is successively sprayed with a cohesive bottom layer with the thickness of 60-100 microns and a lanthanum, cerium, praseodymium, neodymium and other rare earth-containing functional alloy surface layer with the thickness of 150-200 microns. The method comprises the following steps: (1) purification decontamination and sandblasting processing of the ground net surface; (2) allocation of lanthanum, cerium, praseodymium, neodymium and other rare earth-containing alloy powder in zinc, aluminum, magnesium, nickel, manganese, silicon, chromium, beryllium and titanium alloy powder of a surface layer coating; and (3) formation of the rare earth-containing alloy corrosion prevention coating. The electric power ground net surface is sprayed with the rare earth-containing alloy corrosion prevention coating, so that the ground net service life is improved, the ground net work cost is reduced, and the method is simple and reliable in process, green, low-carbon, non-pollution, and friendly to environment.

Owner:STATE GRID CORP OF CHINA +3

Metal additive manufacturing device and method based on high-speed shot peening

PendingCN111185599AOptimize the surface tissue structureImproved resistance to stress corrosion crackingAdditive manufacturing apparatusIncreasing energy efficiencyCorrosionScanning mirror

The invention discloses a metal additive manufacturing device and method based on high-speed shot peening. The metal additive manufacturing device includes peening shot, a shot peening adjustment mechanism, a recycling material box, a forming box, a material storage box, a metal powder preheater, an X-Y scanning mirror, a controller and a continuous laser. According to the metal additive manufacturing device, SLS or DMLS and a shot peening technology are comprehensively used, by precisely controlling continuous laser parameters (including continuous laser spot shape, continuous laser scanningspeed and the like), nozzle diameter, nozzle distance, coverage rate, shot peening speed, quality flow rate, shot peening time and action areas, the surfaces of parts are impacted within a certain period of time, so that the surface structure is refined, residual compressive stress is introduced, and a surface structure is optimized, so that the surface strength and hardness, fatigue-resistance performance, stress-resistance corrosion cracking and high-temperature-oxidation resistance of a metal material can be significantly improved.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

Re modified low-zinc hot-dipped aluminum alloy coating material

InactiveCN103147025AHigh strengthImproved resistance to stress corrosion crackingHot-dipping/immersion processesAlloy coatingZinc

The invention discloses a Re modified low-zinc hot-dipped aluminum alloy coating material. On basis of weight percentage of elements, the alloy comprises 20-25% of Zn, 0.03-0.05% of Sr, 1.5%-2.0% of Mg, 0.1%-0.2% of Cr, 0.05%-0.08% of Cd, 0.4%-0.5% of Si, and the balance being Al and inevitable trace impurities; and a modifier Re2 (CO)10 accounts for 0.001%-0.01% of the total amount of furnace charging materials. In the coating material provided by the invention, the amount of Al that substitutes Zn is greatly improved, thereby reducing dependence on Zn resources.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

A preparation method of high-strength deformed aluminum alloy based on severe plastic deformation

The invention discloses a method for preparing a high-strength deformed aluminum alloy based on severe plastic deformation. The steps of the method are: A. cutting a green body from an aluminum alloy ingot; In the press die, the equal-channel angular extrusion process is carried out continuously with multi-temperature steps that gradually increase in temperature, and the severe plastic deformation technology is used to achieve enhanced solution treatment, and after the end of the water quenching treatment, a supersaturated solid solution block extrusion billet is obtained; C, cutting The alloy rod whose length direction is parallel to the direction of equal-channel angular extrusion is produced; the alloy rod is subjected to conventional hot extrusion processing and aging treatment to obtain high-strength deformed aluminum alloy. The present invention utilizes stage-by-stage severe plastic deformation of gradual heating to realize enhanced solid solution treatment, effectively promotes the dissolution of the second phase, and obtains a single-phase solid solution alloy with fine grain size, high-density defects, and high supersaturation, and then through thermal processing And aging treatment promotes the uniform precipitation of nano-precipitated phases, and obtains high-strength deformed aluminum alloys.

Owner:江苏江南创佳型材有限公司

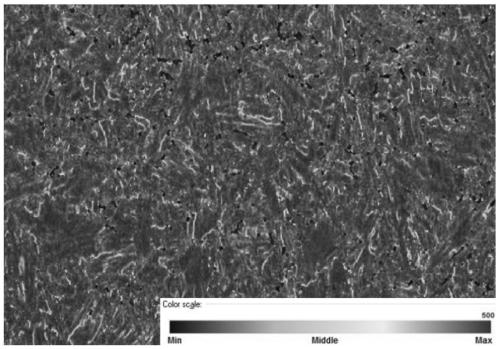

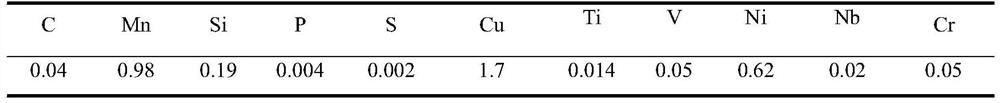

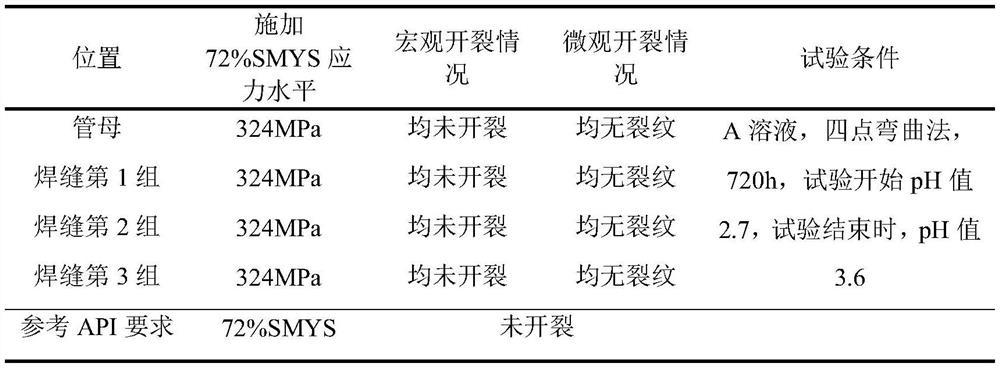

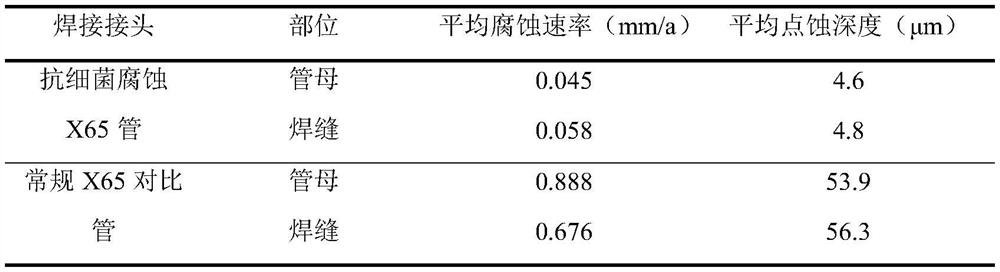

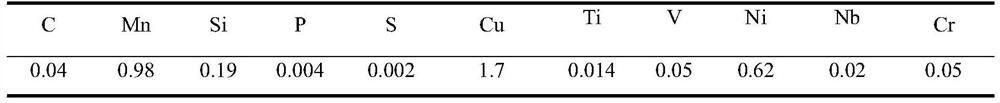

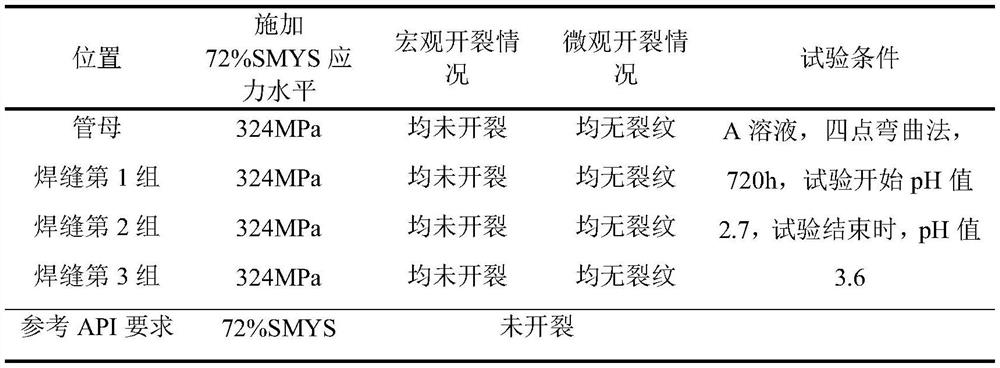

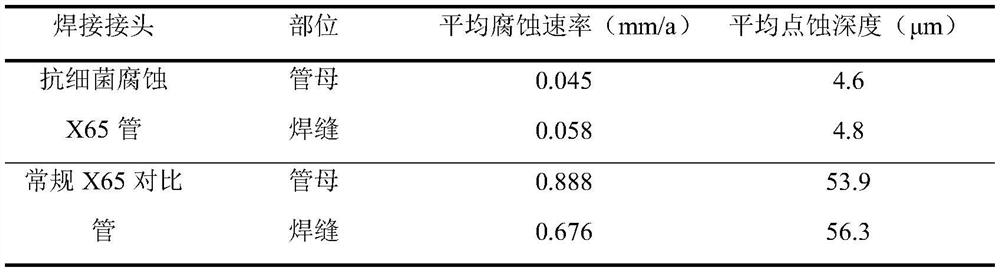

Method for manufacturing bacterial corrosion resistant X65 high efficiency welded pipe (HFW)

The invention discloses a method for manufacturing a bacterial corrosion resistant X65 high efficiency welded pipe (HFW). The method sequentially includes the steps of unwinding butt welding, edge planing, molding, gas shielded high-frequency induction electric resistance welding, welded joint normalizing heat treatment, full pipe body aging heat treatment, sizing flying shear, straightening, ultrasonic inspection, X-ray inspection, water pressing, pipe end chamfering and finished product inspection. Small extrusion amount and small opening angle processes are adopted during forming, after aging heat treatment is combined, the welded pipe has small residual stress, the circumferential opening amount of the pipe body is only measured by a slit-ring method as -20mm - 0mm, low stress and negative value residual stress forming is realized, and the occurrence of sulfide stress corrosion cracking (SSCC) and other corrosion cracking situations of the pipe under the stress action can be prevented. After normalizing heat treatment, the pipe body is subjected to aging heat treatment, so that solid-soluble Cu in the pipe body and a welded joint diffusely precipitates a nanometer Cu-rich phase, and the nanometer Cu-rich phase is the key to improve the antimicrobial corrosion resistance of the welded pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of heat treatment method of al-cu-li alloy pre-aging re-solution re-aging

ActiveCN112281092BPrevent re-precipitationQuenching transfer time is shortSolution treatmentElectrochemical corrosion

The invention discloses a heat treatment method for Al-Cu-Li alloy pre-aging, re-solution and re-aging, which belongs to the field of material heat treatment. Starting from controlling the heat treatment process system and its parameters, the Al-Cu-Li alloy extruded plate is conventionally Solution, pre-aging, heavy solution and re-aging treatments. The conventional solid solution and heavy solution treatment temperature is 515±10°C, heat preservation for 60-90 minutes, and then water quenching, and the quenching transfer time is <5s. The temperature for pre-aging and re-aging treatment is 160-180°C, keep warm for 24-48 hours, and air-cool after taking it out. Re-solution treatment can reduce the strength of the alloy, improve the plasticity of the alloy, and is beneficial to the orthopedic and reprocessing processes; re-aging treatment can effectively control the type, density and distribution of precipitates, and improve the strength of the alloy. Coupled with the coarsening of discontinuous grain boundary precipitates and the increase of copper content in the alloy, the performance of stress corrosion resistance, intergranular corrosion and electrochemical corrosion is improved under the premise of maintaining the strength of the alloy. Increased plasticity. The process is simple and easy and is not limited by the thickness of the plate.

Owner:SHANDONG UNIV

Method for producing 180 aluminium alloy sections

A method for producing 180 aluminium alloy sections relates to a method for producing aluminium alloy sections. The method is used for solving the technical problems that the aluminium alloy section which is produced by the prior art has unstable alloy ingot casting strength, low shear strength, weak tensile strength, low elongation percentage, bad corrosion resistance and bad plasticity. The method for producing 180 aluminium alloy sections comprises the following steps of: 1, weighing raw materials; 2, preparing aluminium alloy melt; 3, producing an aluminium alloy round ingot; 4, homogenizing annealing; 5, producing the aluminium alloy section through extrusion forming; and 6, producing the 180 aluminium alloy section. The 180 aluminium alloy section which is produced by the method has the tensile strength of 310-380 MPa, the shear strength of 200-236MPa and the elongation percentage of 16.0-20.0A, and can be applied in the ship field as the ideal material of ship structures, warship radars and the like.

Owner:哈尔滨东轻特种材料有限责任公司

Alloy powder capable of producing compression stress in the fused-on layer

The alloy powder capable of producing compression stress in the fused-on layer consists of Cr 6.0-12.0 wt%, Ni 5.0-11.0 wt%, Mn 0.5-1.8 wt%, Mo 0.1-0.9 wt%, Nb 0.1- 0.9 wt%, Ti 0.1-0.9 wt%, Si 0.1-0.9 wt%, except Fe. It has grain size of 50-200 microns, solid phase change temperature after melting and solidifying of 100-300 deg.c, and structure comprising martensite in 50-90 % and austenite in 10-50 %. The present invention is used in raising the fatigue resistance, stress corrosion resistance, safety and service life of iron and steel material, mechanical structure and equipment. The method and material of the present invention may be used in producing composite material product with compression stress in the surface.

Owner:TIANJIN UNIV

A steel core wire anti-corrosion alloy coating for overhead wires and preparation method thereof

ActiveCN109371285BImprove adhesionLong corrosion lifeHot-dipping/immersion processesSalt spray testManganese

The present invention is a steel core wire anti-corrosion alloy coating for overhead wires and a preparation method thereof, which contains 5-10% aluminum, 0.005-0.2% rare earth, 0.005-0.2% silver, 0.05-0.5% manganese, 0.05‑1.0% chromium, balance zinc and unavoidable impurities. The alloy coating prepared by adopting the proportioning of the present invention has better corrosion resistance: taking the yellow rust occurrence time as the failure standard of the alloy coating, under the same condition of coating thickness, the corrosion resistance of the alloy coating of the present invention is better than that of hot-plated coating. The pure zinc coating is improved by more than 15 times; with the salt spray test weight loss as the corrosion resistance assessment standard of the alloy coating, under the same condition of the coating thickness, the corrosion resistance of the alloy coating of the present invention is more than 15 times higher than that of the industrial hot-dip pure zinc coating.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +3

Sand cast high pressure pump head aluminum bronze

InactiveCN103088231BImprove compactnessImproved resistance to stress corrosion crackingNonferrous metalSand casting

The invention provides aluminium bronze of a sand-casting high-pressure pump head, belonging to the technical field of new non-ferrous materials. The aluminium bronze comprises 9-11.5 % of Al, 2.5-5.0 % of Fe, less than or equal to 3.5 % of Mn, 3.0-6.0 % of Ni, 0.05-0.2 % of Sn, 0.01-0.5 % of Cr, 0.5-1.0 % of Zn, 0.015-0.2 %, and the balance being Cu and less than 1 % of usual impurities. The alloy is high in mechanical properties and pressure resistance of castings, and can be used in related fields of high-voltage submersible pump heads.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

A kind of manufacturing method of anti-bacterial corrosion x65 HFW welded pipe

The invention discloses a method for manufacturing an anti-bacterial corrosion X65HFW welded pipe, which sequentially includes uncoiling butt welding, planing, forming, gas-protected high-frequency induction resistance welding, normalizing heat treatment of weld seams, aging heat treatment of the whole pipe body, sizing and flying Trimming, straightening, ultrasonic inspection, X-ray inspection, hydraulic pressure, pipe end chamfering and finished product inspection. The present invention adopts small extrusion amount and small opening angle technology when forming, combined with aging heat treatment, the welded pipe has small residual stress, and the circumferential opening of the pipe body measured by the cutting ring method is only -20 ~ 0mm, low stress and negative residual stress forming , can prevent corrosion and cracking of pipes such as SSCC under stress. After the normalizing heat treatment, aging heat treatment is performed on the pipe body, so that the solid solution Cu in the pipe body and welded joints is dispersed and precipitated into a nano-Cu-rich phase. This nano-Cu-rich phase is the core key to improving the anti-microbial corrosion performance of the welded pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com