Method for increasing stress corrosion resistance of Fe-Ni-based anticorrosion alloy oil well pipe

A technology of corrosion-resistant alloys and corrosion performance, which is applied in the field of corrosion-resistant alloy processing and metal materials, can solve problems such as economic loss and safety hazards, stress corrosion, stress corrosion cracking failure, etc., to reduce development costs and improve stress corrosion cracking resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The chemical composition (mass percentage) of the iron-nickel-based corrosion-resistant 028 alloy is as follows:

[0026] C 0.012%

[0027] Si 0.23%

[0028] Mn 0.74%

[0029] P 0.018%

[0030] S 0.001%

[0031] Cr 27.2%

[0032] Ni 31.3%

[0033] Mo 3.7%

[0034] Cu 1.1%

[0035] The balance is Fe and other unavoidable impurities.

[0036] Using the above alloys, the iron-nickel-based corrosion-resistant 028 alloy P110 grade oil well pipes were prepared through the following steps and schemes, and made into the first category:

[0037] (1) Prepare a blank tube with an outer diameter of 250mm and a wall thickness of 25mm by hot extrusion;

[0038] (2) A cold-rolled pipe with an outer diameter of 219 mm and a wall thickness of 16 mm was prepared by using a 350-type Pilger cold rolling mill;

[0039] (3) The chamber-type annealing furnace heated by natural gas is annealed at 1210±5°C for 75±5 minutes by heating with the furnace;

[0040] (4) Use a 350-type Pilg...

Embodiment 2

[0055] The chemical composition (mass percentage) of the iron-nickel-based corrosion-resistant 028 alloy is as follows:

[0056] C 0.015%

[0057] Si 0.19%

[0058] Mn 0.72%

[0059] P 0.020%

[0060] S 0.002%

[0061] Cr 26.7%

[0062] Ni 31.5%

[0063] Mo 3.8%

[0064] Cu 1.2%

[0065] The balance is Fe and other unavoidable impurities.

[0066] Using the above alloys, the iron-nickel-based corrosion-resistant 028 alloy Q125 grade oil well pipes were prepared through the following steps and schemes, and made into the first category:

[0067] (1) Prepare a blank tube with an outer diameter of 250mm and a wall thickness of 25mm by hot extrusion;

[0068] (2) A cold-rolled pipe with an outer diameter of 219 mm and a wall thickness of 16 mm was prepared by using a 350-type Pilger cold rolling mill;

[0069] (3) The chamber-type annealing furnace heated by natural gas is annealed at 1200±5°C for 75±5 minutes by heating with the furnace;

[0070] (4) The 350-type Pilger...

PUM

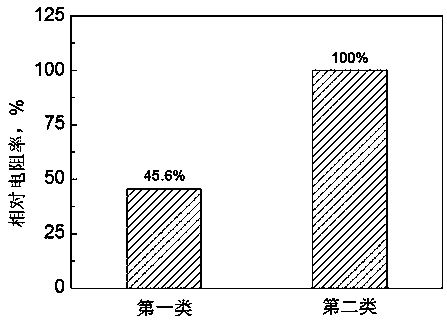

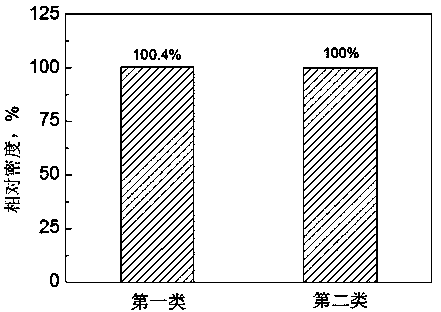

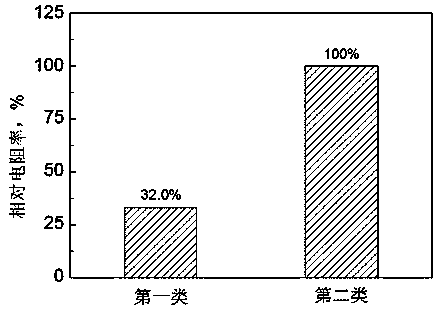

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com