Method for preparing high-strength wrought aluminum alloy based on severe plastic deformation

A technology of severe plastic deformation and deformation of aluminum alloy, which is applied in the field of aluminum alloy processing, can solve problems such as unfavorable alloy strength and toughness, weakening of thermal processing effect, and fine grain growth, so as to achieve small grain size, improve processing performance, and reduce content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

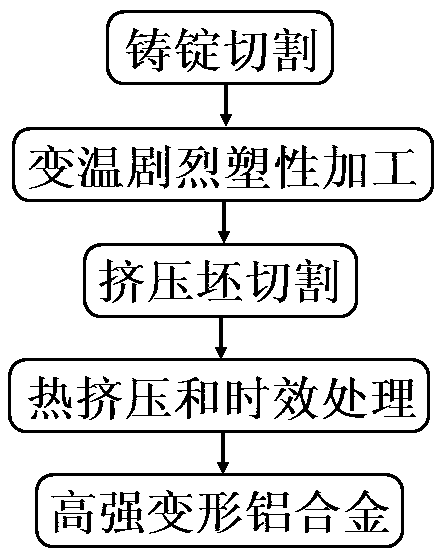

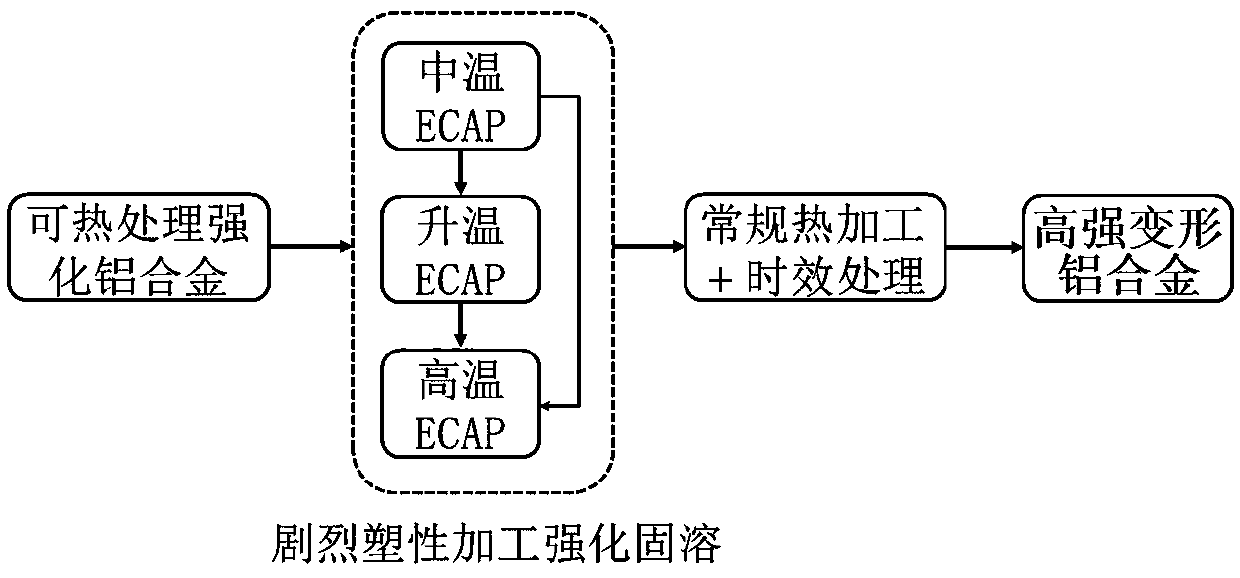

[0030] Such as Figure 1-2 Shown: a preparation method of a high-strength deformed aluminum alloy based on severe plastic deformation, the steps of the preparation method are as follows:

[0031] A. Ingot cutting: Cut a billet with a size of 50mm×50mm×100mm from an aluminum alloy ingot with aging strengthening effect;

[0032] B. Severe plastic processing with variable temperature: Place the billet in the rotary die and other channel angular extrusion molds, and use the multi-temperature steps that gradually increase the temperature to continuously perform equal channel angular extrusion processing, and the medium channel angular extrusion processing is generally divided into three stage; the first stage is equal-channel angular extrusion processing in the middle temperature stage, the processing temperature is 400-420 ° C, and the processing pass is 1 pass; the second stage is equal-channel angular extrusion processing in the heating stage, the processing temperature is 430-4...

Embodiment 1

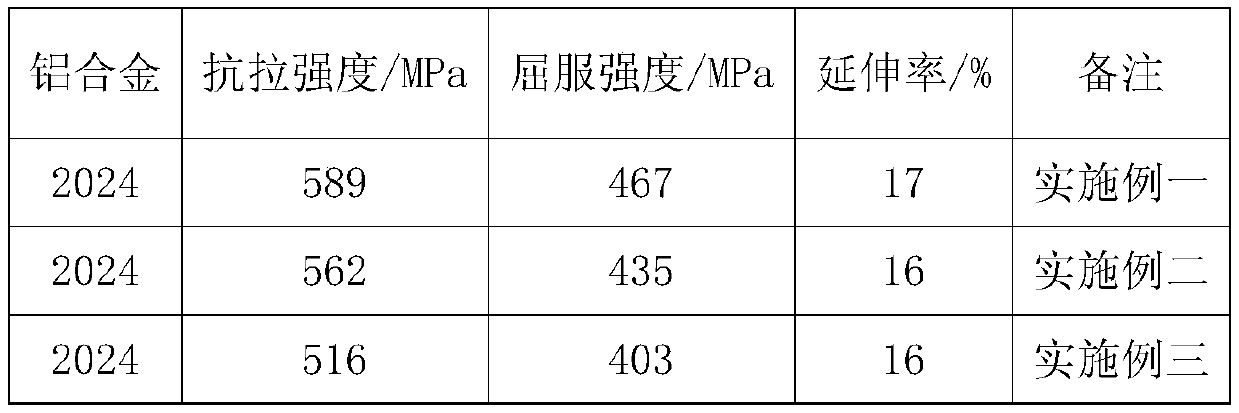

[0038] The 2024 aluminum alloy ingot is cut into a billet with a size of 50mm×50mm×100mm; the billet is placed in a rotary equal-channel angular extrusion die for continuous equal-channel angular extrusion processing, and the first-pass processing temperature is 400°C , The processing temperature of the second pass is 440°C, the processing temperature of the third and fourth passes is 470°C, and then quenched in water to obtain a supersaturated solid solution block extrusion billet; cut out the diameter from the above block extrusion billet It is a 45mm alloy rod, and the length direction of the alloy rod is parallel to the direction of equal channel angular extrusion; the alloy rod is subjected to subsequent conventional hot extrusion processing and aging treatment to obtain a high-strength deformed aluminum alloy based on severe plastic deformation.

Embodiment 2

[0040] Cut the 2024 aluminum alloy ingot into a billet with a size of 50mm×50mm×100mm; the billet is placed in a rotary die and equal channel corner extrusion die for continuous equal channel corner extrusion processing, and the first pass processing temperature is 410°C , The processing temperature of the second pass is 450°C, the processing temperature of the third and fourth passes is 480°C, and then quenched in water to obtain a supersaturated solid solution block extrusion billet; cut out the diameter from the above block extrusion billet It is a 45mm alloy rod, and the length direction of the alloy rod is parallel to the direction of equal channel angular extrusion; the alloy rod is subjected to subsequent conventional hot extrusion processing and aging treatment to obtain a high-strength deformed aluminum alloy based on severe plastic deformation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com