Steel sheet applicable to ultrahigh heat input welding and manufacturing method thereof

A manufacturing method and technology of super-large wire, applied in the field of low-alloy high-strength steel, to achieve the effect of being conducive to popularization and application, microstructure refinement, and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

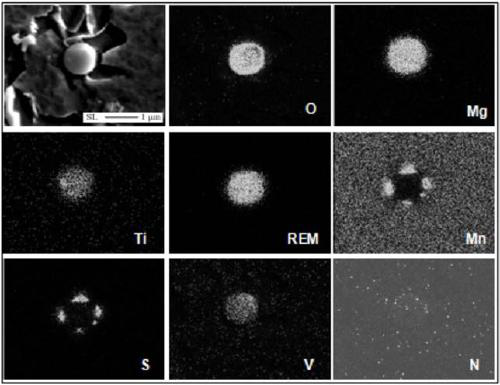

[0026] In this embodiment, the steel plate suitable for ultra-large heat input welding, its chemical composition includes by weight percentage: C 0.1%, Si 0.2%, Mn 1.1%, Nb 0.015%, V 0.025%, Ti 0.025%, P 0.003% , S 0.003%, Cu 0.02%, Ni 0.1%, Cr 0.1%, Mo 0.05%, B 0.0001%, N 0.005%, O 0.002%, Al 0.005%, Mg 0.001%, Zr 0.01%, the balance is Fe ; Among the inclusions with a size of 0.5-5 μm in the steel plate, the number of Ti-Mg-Zr-O-Mn-S composite inclusions accounts for 40%; among the inclusions with a size of 0.02-0.5 μm in the steel plate, the number of MgO type The number accounts for 35%; 35% of the number of inclusions in the steel plate have V carbonitrides precipitated.

[0027]The manufacturing method of the above-mentioned steel plate: pre-deoxidize silicon manganese aluminum in the molten steel smelting process, add Ti and V when the oxygen is set to 20ppm, add Zr when the oxygen is further set to 10ppm at 1.5min, and add Mg when the oxygen is set to 5ppm again after 1...

Embodiment 2

[0030] In this embodiment, the steel plate suitable for ultra-large heat input welding, its chemical composition includes by weight percentage: C 0.15%, Si 0.1%, Mn 2.0%, Nb 0.05%, V 0.1%, Ti 0.015%, P 0.002% , S 0.005%, Cu0.5%, Ni 0.5%, Cr 0.01%, Mo 0.5%, B 0.002%, N 0.008%, O 0.005%, Al 0.015%, Mg0.0005%, REM (rare earth elements) 0.01% , the balance is Fe; among the inclusions with a size of 0.5-5 μm in the steel plate, the number of Ti-Mg-REM-O-Mn-S composite inclusions accounts for 30%; among the inclusions with a size of 0.02-0.5 μm in the steel plate, The number of MgO-type inclusions accounts for 15%; 50% of the number of inclusions in the steel plate have V carbonitrides precipitated.

[0031] The manufacturing method of the above-mentioned steel plate: during the molten steel smelting process, silicon-manganese-aluminum pre-deoxidation is used, Ti and V are added when the oxygen is set to 200 ppm, REM is further added when the oxygen is set to 90 ppm in 8 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com