Preparation method of high-molecular polylactic acid (PLA) three-dimensional composite material capable of being crystallized rapidly

A high-molecular-weight, polylactic acid technology, applied in the field of preparation of high-molecular-weight polylactic acid stereocomposite materials, can solve the problems of complex chemical structures of nucleating aids, affecting large-scale applications, and high preparation costs, and achieve large-scale industrial production , Improve nucleation effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

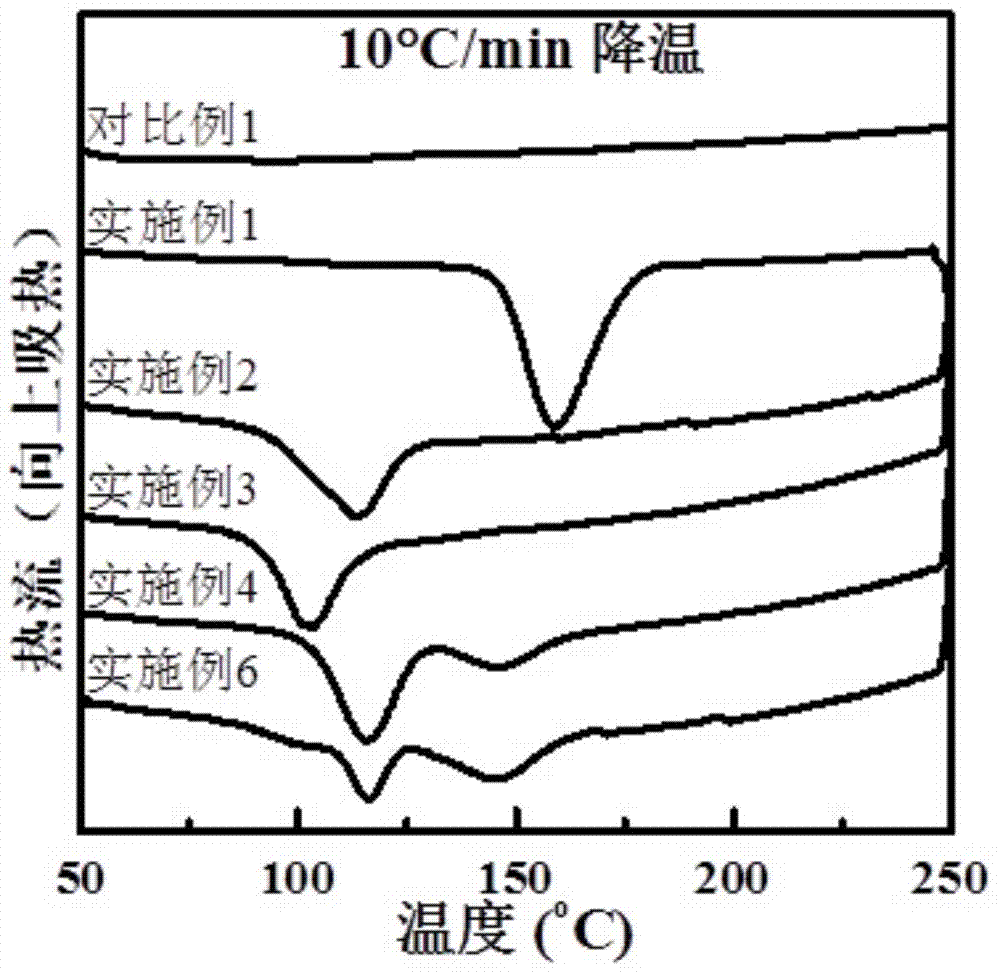

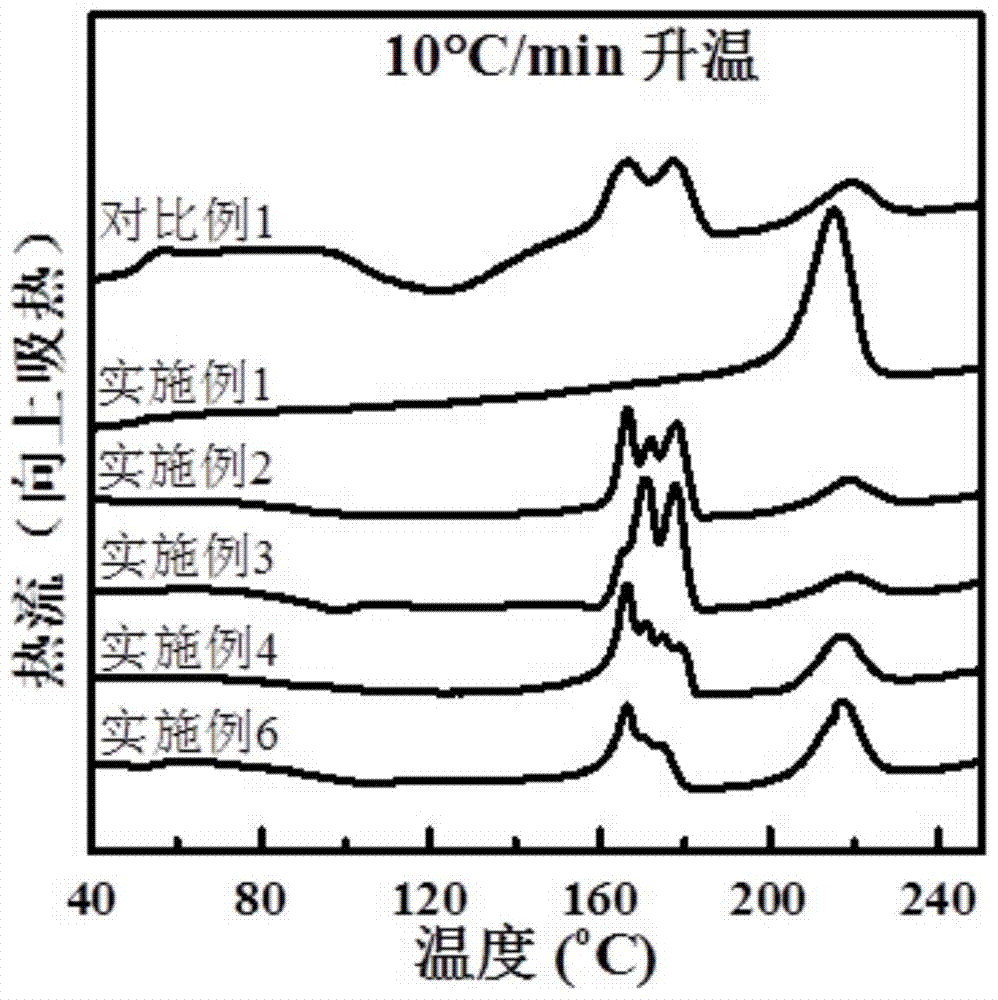

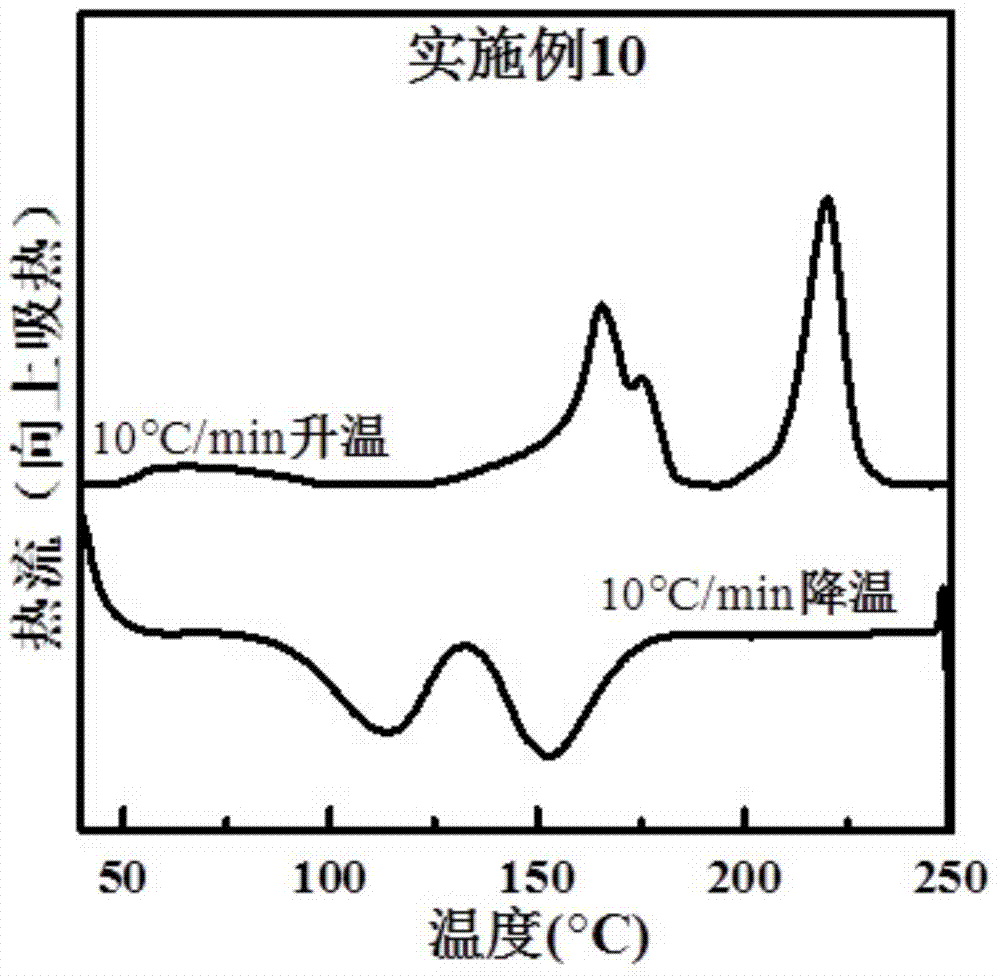

[0039] A method for preparing a rapidly crystallizable high molecular weight polylactic acid stereocomplex material, the specific preparation steps include: taking PLLA, PDLA, and an organometallic phosphonate nucleating agent, and adopting solution or melt blending to obtain a rapidly crystallizable high Molecular weight polylactic acid stereocomposite material; wherein, the mass of the organometallic phosphonate nucleating agent accounts for 0.1% to 3% of the total composition, the mass of the polylactic acid matrix accounts for 99.9 to 97% of the total composition, and the mass percentage of each component The sum is 100%; the mass percentage of PLLA in the polylactic acid matrix is 50% to 90%, and the mass percentage of PDLA is 10% to 50%. The solution and melt blending method of PLLA, PDLA and crystallization nucleating agent in the present invention are not particularly limited, and known methods can be used.

[0040] When using the solution blending method to prepare,...

Embodiment 1~7

[0060] Embodiment 1~7 is prepared by solution method blending

[0061] The mass percentage of the polylactic acid matrix is 99%, and the mass percentage of different types of nucleating agents is 1%. PLLA, PDLA and nucleating agent were weighed according to the composition mass ratio in Table 1, and then dissolved in chloroform, the concentration of the polymer solution was 50g / L, stirred to make it evenly mixed, and then cast in a polytetrafluoroethylene petri dish, The solvent was completely evaporated at room temperature, and then dried in a vacuum oven at 60 °C for 6 h. Wherein, if chloroform is replaced by dichloromethane, the preparation of this embodiment can also be completed.

Embodiment 8

[0062] Embodiment 8 is prepared by melt blending

[0063] The mass percentage of the polylactic acid matrix is 99%, and the mass percentage of the nucleating agent is 1%. Premix 49.5 parts by mass of PLLA, 49.5 parts by mass of PDLA, and 1 part by mass of PPZn according to the composition and mass ratio in Table 1, and then add them to the HAAKE MiniLab II twin-screw mixer, knead at 230°C for 3 minutes, and then extrude and pelletize.

[0064] In order to further illustrate the nucleating effect of the nucleating agent in the blend system of equal amounts of PLLA and PDLA, in Comparative Example 1, only the same amount of PLLA and PDLA were blended by solution method. Weigh 50 parts by mass of PLLA and 50 parts by mass of PDLA according to the composition and mass ratio in Table 1. In the solution chloroform, the concentration of the polymer solution is 50g / L, stir to make it evenly mixed, and then cast it on a polytetrafluoroethylene petri dish The solvent was completely e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com