Shot peening system for inner wall of steel cylinder

A shot peening and rust removal, steel cylinder technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc. Fatigue strength limit, the effect of improving stress corrosion cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

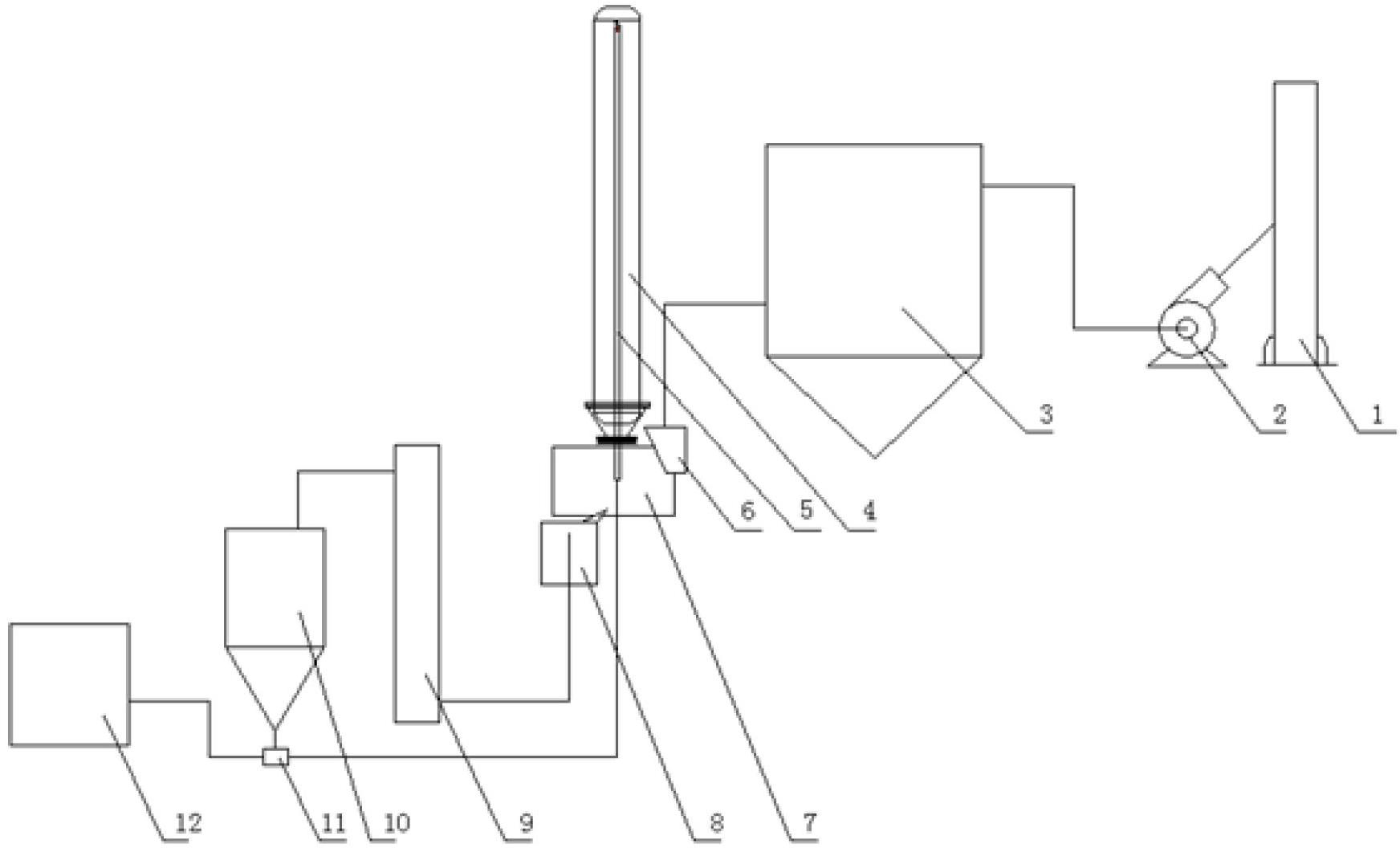

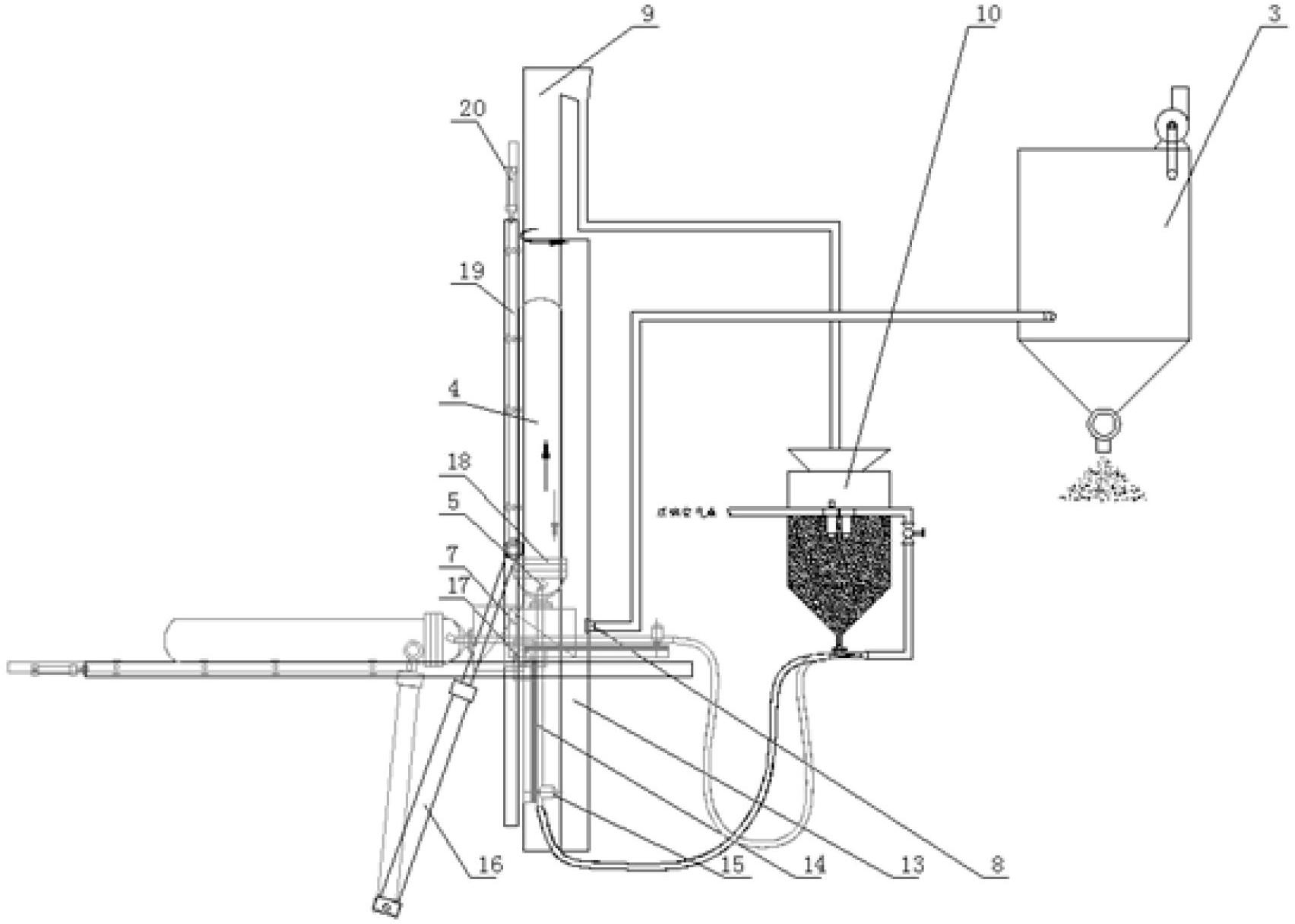

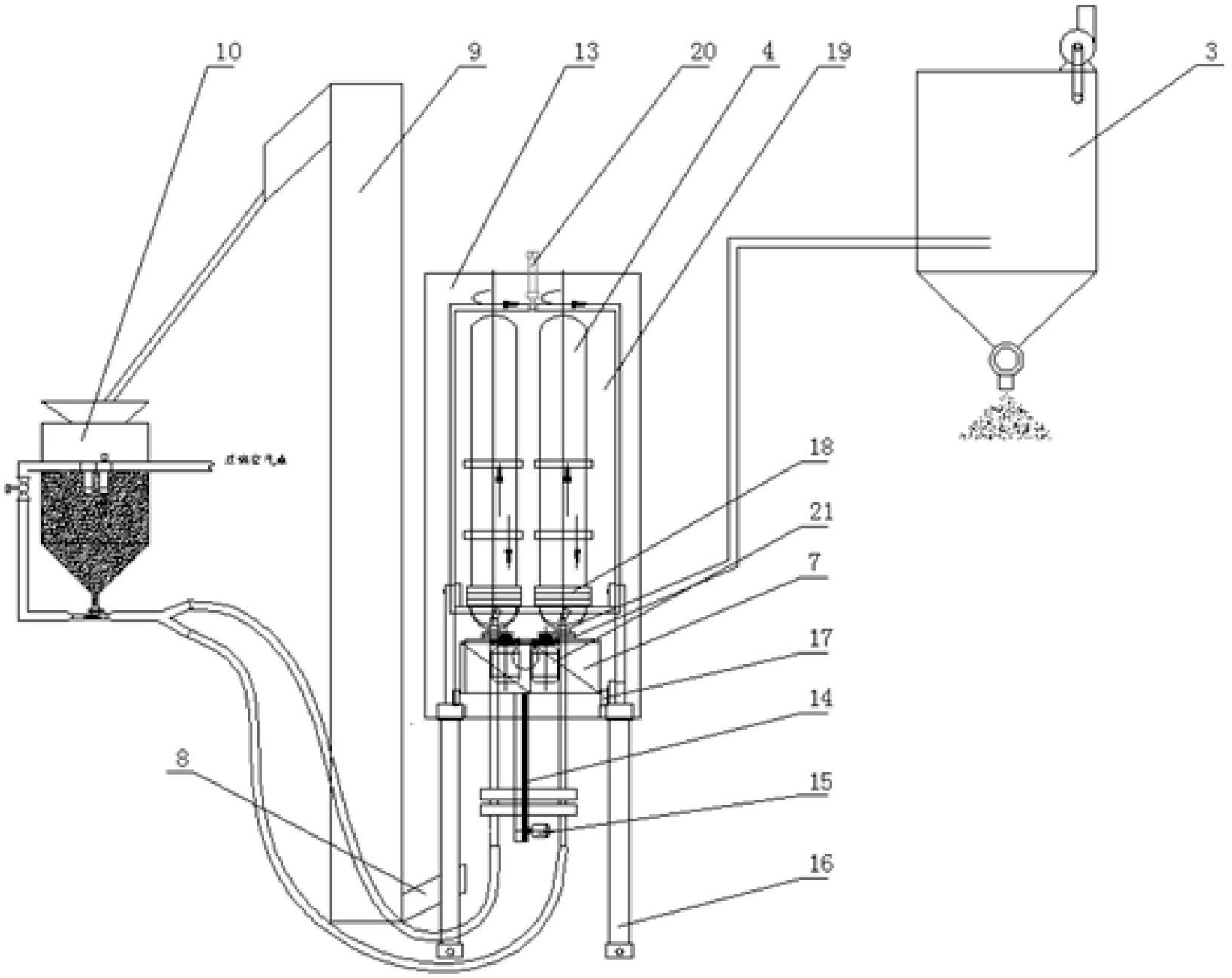

[0018] A shot peening rust removal system for the inner wall of a steel cylinder, including a compressed air source 12, a sandblasting tank 10, a recovery bucket lift 9, a recovery bucket 8, a driving device 7, a dust collection cover 6, a steel cylinder 4, a sandblasting gun 5, and a sandblasting treatment device, dust collector 3, fan 2 and chimney 1, the compressed air source sends the shot blasting in the sand blasting tank to the sand blasting gun of the sand blasting treatment device through the sand blasting valve 11, the sand blasting gun is coaxially placed in the steel cylinder, and the steel cylinder The shot blasting inside is recovered through the recovery hopper, and the shot blasting is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com