Method for manufacturing bacterial corrosion resistant X65 high efficiency welded pipe (HFW)

A manufacturing method and anti-bacterial technology, applied in the field of oil and gas pipes, can solve the problems of research and development of anti-bacterial corrosion welded pipes and product report information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment: Take the manufacture of X65 steel grade Φ219.1×6.3mm anti-bacterial corrosion HFW welded pipe as an example.

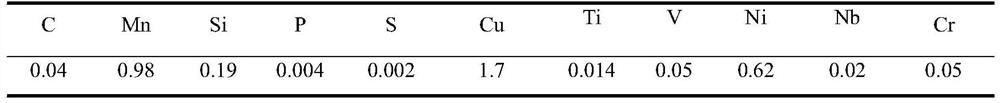

[0021] Table 1 Analysis of chemical composition of X65 coil (wt%)

[0022]

[0023] (1) Raw materials: X65 anti-bacterial corrosion coil with a wall thickness of 6.3 mm is used, and its chemical composition is shown in Table 1.

[0024] (2) Manufacture of welded pipe: Anti-bacterial corrosion X65 hot-rolled coils are used to produce HFW welded steel pipes with an outer diameter of 219.1mm and a wall thickness of 6.3mm. After uncoiling, leveling, and edge milling, the width of the strip steel is accurately controlled at 691.3-691.7mm, and then the head and tail of the strip steel are butt-welded, and the edge of the strip steel is ±0.25mm.

[0025] Forming: roll forming is used to control the edge waveform of the board.

[0026] Gas-shielded high-frequency induction resistance welding: When using high-frequency induction resistance welding, in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com